Production technology for extracting eucommia flavonoid from eucommia ulmoides leaves by combining compound enzyme with ultrasound

A technology of Eucommia flavonoids and production process, which is applied in the directions of medical preparations containing active ingredients, food science, plant raw materials, etc., can solve the problems of backward production methods, high equipment costs and high operating temperature, and achieves less impurity content and extraction speed. Fast, easy-to-purify results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

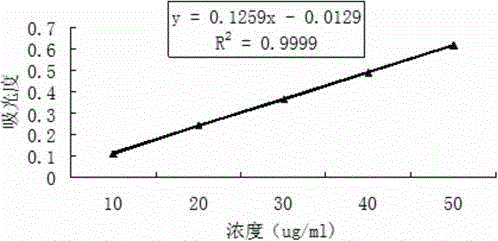

Image

Examples

Embodiment 1

[0019] Weigh 500g of dried leaves of Eucommia ulmoides, crush them, pass through 50 mesh, add water to the powder and soak for half an hour; add 1.2g of cellulase and 3.9g of pectinase to it; adjust the pH to 5.0 with hydrochloric acid solution, and enzymatically hydrolyze at 49°C for 3h , and then boiled for 4min to inactivate the enzyme; add ethanol to the mixed solution until the concentration of ethanol is 50wt%, the ratio of solid to liquid is 1:42 (volume ratio, the same below), ultrasonic extraction for 22min, the temperature is 95 ℃, the power was 76%, the ultrasonic product was filtered, the filtrate was concentrated, and the pH was adjusted to 6.5 to obtain an extract.

[0020] Slowly add the above extract to the D-101 macroporous adsorption resin, and add the sample to 1 / 3 of the column. Water and ethanol with a concentration of 10wt% were selected for elution in sequence, and the eluent was discarded. Then elute with ethanol with a concentration of 90wt%, collect ...

Embodiment 2

[0022] Weigh 500g of dried leaves of Eucommia ulmoides, crush them, pass through 50 mesh, add water to the powder and soak for half an hour; add 0.6g of cellulase and 2.4g of pectinase to it; adjust the pH to 4.0 with hydrochloric acid solution, and enzymatically hydrolyze at 45°C for 2h , and then boiled for 2 minutes to inactivate the enzyme; add ethanol to the mixed solution until the concentration of ethanol is 50wt%, the ratio of solid to liquid is 1:40, ultrasonic leaching for 15min, the temperature is 90°C, the power is 70%, and the ultrasonic product is filtered , the filtrate was concentrated, and the pH was adjusted to 6.2 to obtain an extract.

[0023] Slowly add the above extract to the D-101 macroporous adsorption resin, and add the sample to 1 / 3 of the column. Water and ethanol with a concentration of 10wt% were selected for elution in sequence, and the eluent was discarded. Then elute with ethanol with a concentration of 90wt%, collect the eluent, concentrate, ...

Embodiment 3

[0025] Weigh 500g of dried leaves of Eucommia ulmoides, crush them, pass through 50 mesh, add water to the powder and soak for half an hour; add 1.2g of cellulase and 4.8g of pectinase to it; adjust the pH to 5.0 with hydrochloric acid solution, and enzymatically hydrolyze at 55°C for 3h , and then boiled for 4 minutes to inactivate the enzyme; add ethanol to the mixed solution until the concentration of ethanol is 50wt%, the ratio of solid to liquid is 1:45, ultrasonic extraction is 25min, the temperature is 100°C, the power is 80%, and the ultrasonic product is filtered , the filtrate was concentrated, and the pH was adjusted to 6.5 to obtain an extract.

[0026] Slowly add the above extract to the AB-8 macroporous adsorption resin, and add the sample to 1 / 3 of the column. Water and ethanol with a concentration of 10wt% were selected for elution in sequence, and the eluent was discarded. Then elute with ethanol with a concentration of 90wt%, collect the eluent, concentrate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com