CeO2 (Cerium Oxide) nano-particle/CdS (Cadmium Sulfide) nano-rod composite photo-catalyst as well as preparation method and application thereof

A nanoparticle and nanorod technology, applied in the field of composite photocatalyst preparation, achieves the effects of high strength, high recyclability and strong light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

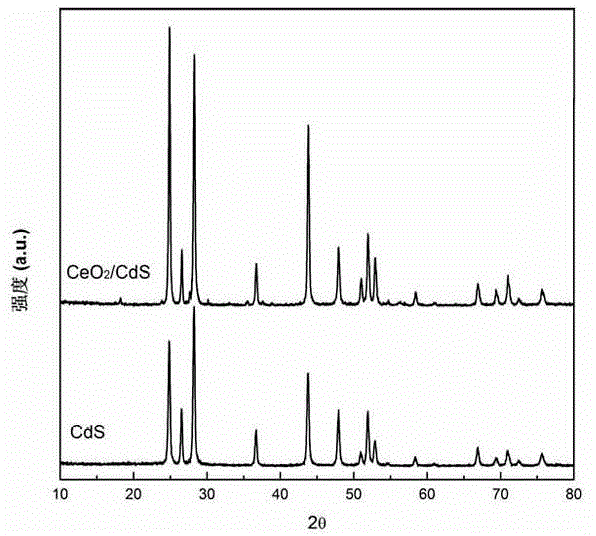

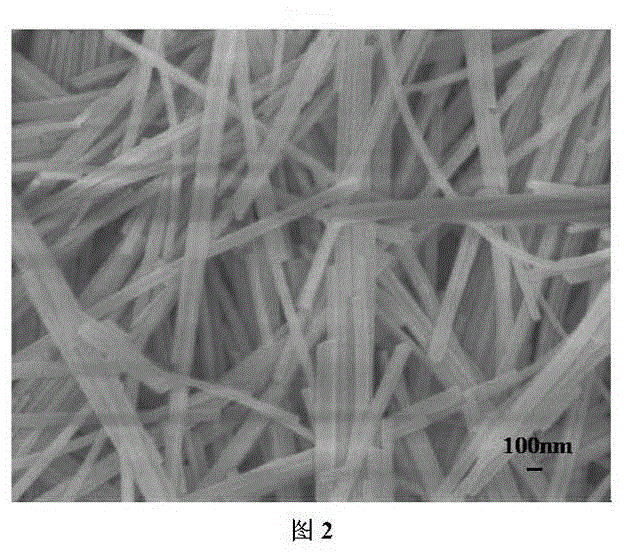

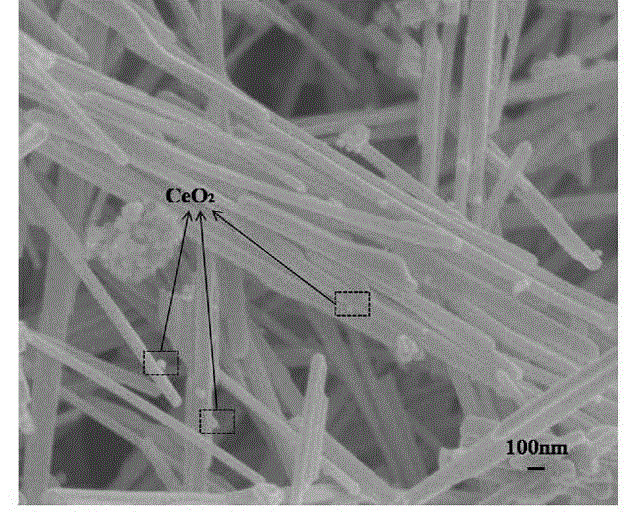

[0045] A kind of CeO of the present invention 2 Nanoparticles / CdS nanorod composite photocatalyst, with one-dimensional structure of CdS nanorods as the matrix, CeO 2 Nanoparticles are decorated on the surface of CdS nanorods.

[0046] where CeO 2 The nanoparticles are spherical crystals with a diameter of 10nm-25nm, and the band gap is 3.2eV; the CdS nanorods are CdS nano-rod crystals with a length of 1μm-2μm and a diameter of 100nm, and a band gap of 2.4eV.

[0047] CeO 2 The preparation method of nanoparticle / CdS nanorod composite photocatalyst comprises the following steps:

[0048] (1) Preparation of CdS nanorods:

[0049] a. Weigh 3.12g sodium diethyldithiocarbamate and 1.269g CdCl respectively 2 2.5H 2 O was poured into a 600ml beaker, and then 450ml of deionized water was added thereto, ultrasonicated for 30min and stirred for 1h to fully react the raw materials.

[0050] b. After fully reacting in step a, the reaction product was left to stand for 30 minutes, a...

Embodiment 2

[0062] This embodiment is basically the same as Example 1, the only difference is that in step (2) Ce(NO 3 ) 3 ·6H 2 O dosage is 6.012mg.

Embodiment 3

[0064] This embodiment is basically the same as Example 1, the only difference is that in step (2) Ce(NO 3 ) 3 ·6H 2 O dosage is 18mg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com