Molybdenum disulfide-antimony sulfide composite material and its preparation method and application

A technology of molybdenum disulfide and composite materials, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of low photocatalytic activity, low quantum efficiency, narrow band gap energy, etc., and achieve High photocatalytic activity, fast electron transfer rate, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

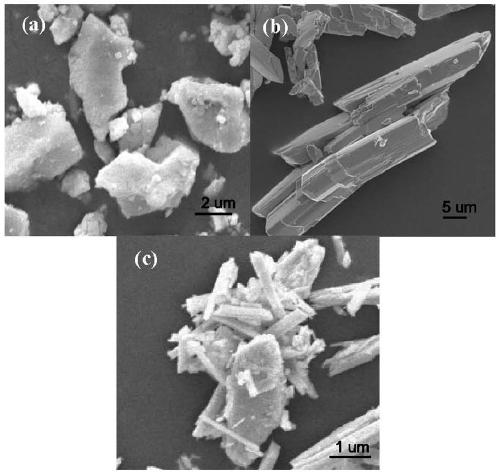

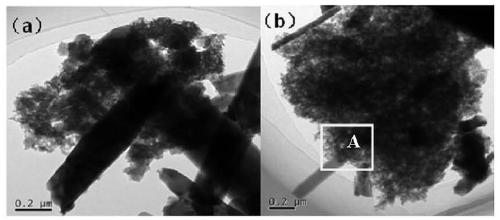

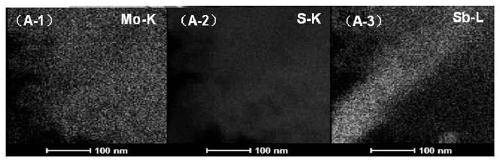

[0037] A molybdenum disulfide-antimony sulfide composite material of the present invention, the composite material includes molybdenum disulfide and antimony sulfide, wherein the molybdenum disulfide is in the form of blocks, the antimony sulfide is in the form of rods, and the block-shaped molybdenum disulfide is doped in the rod-shaped sulfide Antimony surface and middle, wherein the mass fraction of molybdenum disulfide is 8%.

[0038] A method for preparing the molybdenum disulfide-antimony sulfide composite material of the above-mentioned present embodiment, comprising the following steps:

[0039] (1) Dissolve 242mg of sodium molybdate and 601mg of thioacetamide (the molar ratio of the two is 1:8) in deionized water, transfer to a polytetrafluoroethylene tank, heat to 180°C for hydrothermal synthesis, and maintain for 24 Hours later, cool naturally. The reaction product was washed successively with deionized water and absolute ethanol, and then centrifuged at a centrifu...

Embodiment 2

[0047] A molybdenum disulfide-antimony sulfide composite material of the present invention comprises molybdenum disulfide and antimony sulfide, wherein the molybdenum disulfide is block-shaped, the antimony sulfide is rod-shaped, and the block-shaped molybdenum disulfide is doped on the rod-shaped antimony sulfide surface and In the middle, the mass fraction of molybdenum disulfide is 5%.

[0048] A method for preparing the molybdenum disulfide-antimony sulfide composite material of the above-mentioned embodiment differs from the preparation method of embodiment 1 only in that the amount of molybdenum disulfide in step (2) is 10 mg, and the rest of the steps are the same.

Embodiment 3

[0050] A molybdenum disulfide-antimony sulfide composite material of the present invention comprises molybdenum disulfide and antimony sulfide, wherein the molybdenum disulfide is block-shaped, the antimony sulfide is rod-shaped, and the block-shaped molybdenum disulfide is doped on the rod-shaped antimony sulfide surface and In the middle, the mass fraction of molybdenum disulfide is 11%.

[0051] A preparation method of the molybdenum disulfide-antimony sulfide composite material of the above-mentioned embodiment is different from the preparation method of embodiment 1 only in that the amount of molybdenum disulfide in step (2) is 20 mg, and the rest of the steps are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com