A continuous jet dispersion method for micron and nanometer dry powder particles

A granule and dry powder technology, applied in conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of small geometric mean deviation, difficulty in dispersion of nanoparticles, and inappropriate dispersion of nanoparticles, achieving strong applicability, spraying Diffuse control for convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further explained below with reference to the drawings and examples.

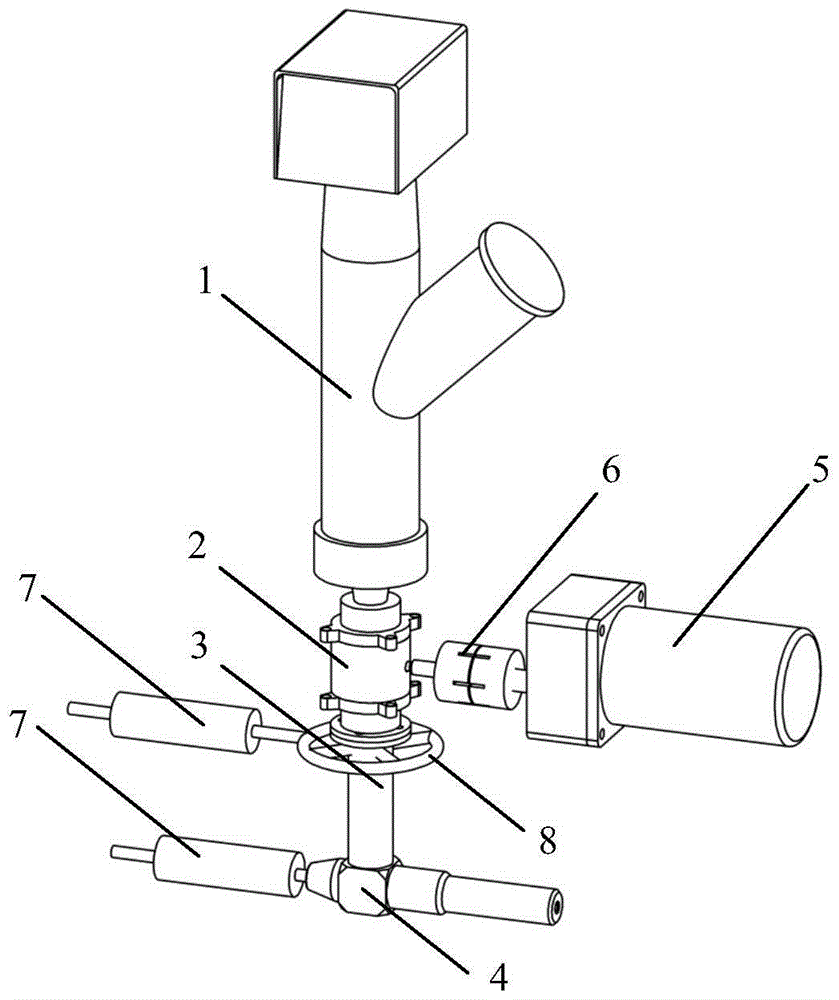

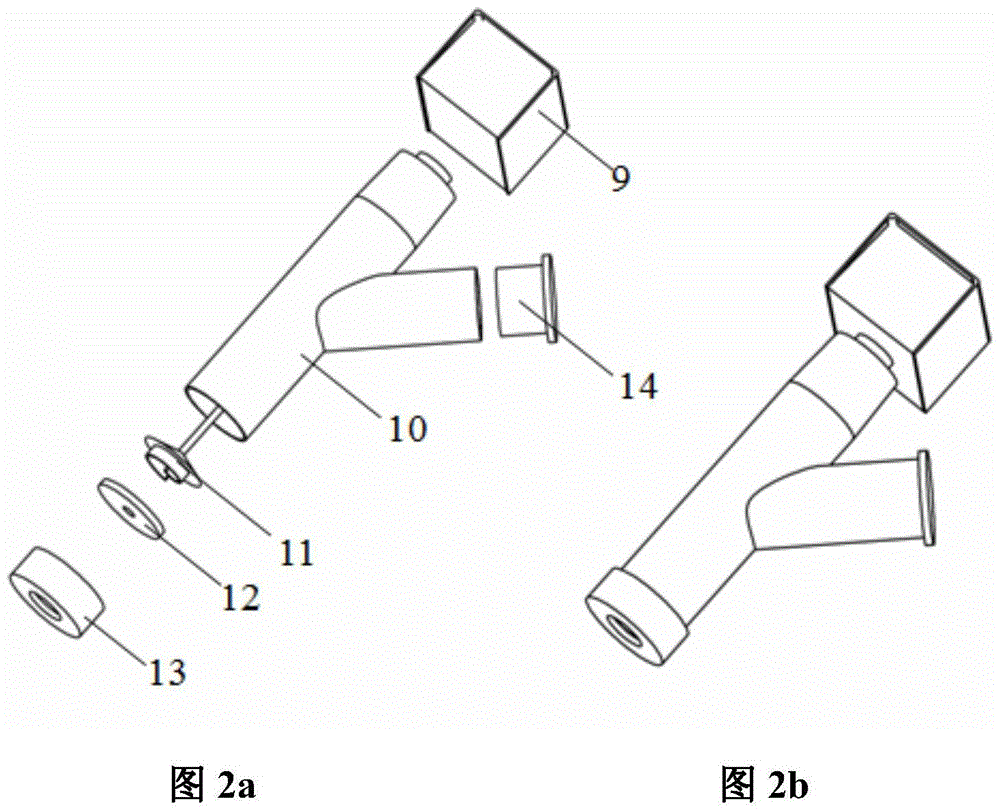

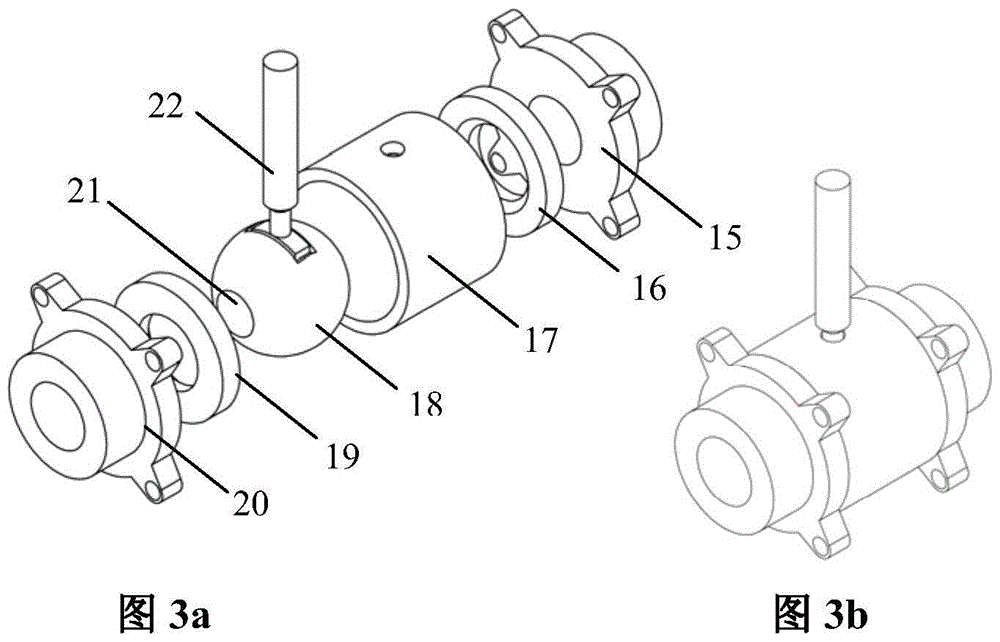

[0031] As shown in the figure, the overall implementation of the present invention is:

[0032] Put a certain amount of granular powder into the remaining material container 10 from the feeding port of the feeder 1 and smooth it slightly; adjust the speed of the geared motor 5, generally 30rpm or 60rpm can meet the requirements; in the equalizing tube Install an air purification unit 7, such as a filter cartridge or a high-efficiency filter, at the gas inlet of 8 to prevent the impure gas from entering the vacuum end of the vacuum generator through the catcher 3 from polluting dispersed aerosols; when running, turn on the vacuum generator 4 first The upstream valve of the inlet causes compressed air to enter the vacuum generator 4, and its vacuum end 27 then begins to generate negative pressure; the feed rate is set by controlling the speed of the feeder stepping motor 9, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com