A kind of preparation method of metallic graphene

A graphene and metallic technology, applied in the field of preparation of metallic graphene, can solve problems such as unfavorable applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of metallic graphene provided by the invention, the method comprises the steps:

[0032] Step a. Put the clean copper sheet into the chemical vapor deposition furnace that has been vacuumed, and feed the hydrogen gas with a flow rate of 40 standard milliliters per minute. After the chemical vapor deposition furnace is heated up to 1000 degrees Celsius, the flow rate is 60 Standard milliliters of methane gas per minute, shut off the methane gas after 15 minutes, cool down the chemical vapor deposition furnace to room temperature, take out the copper sheet, spin-coat polymethyl methacrylate on the copper sheet on the side that contacts the methane gas, and then Put the copper sheet into the ferric chloride solution, and after 30 minutes, use a clean silicon chip to remove the film suspended on the ferric chloride solution, and wash the film on the silicon chip with acetone to obtain Graphene on a sheet;

[0033]Step b. Metals such as gold, copper, ...

Embodiment 1

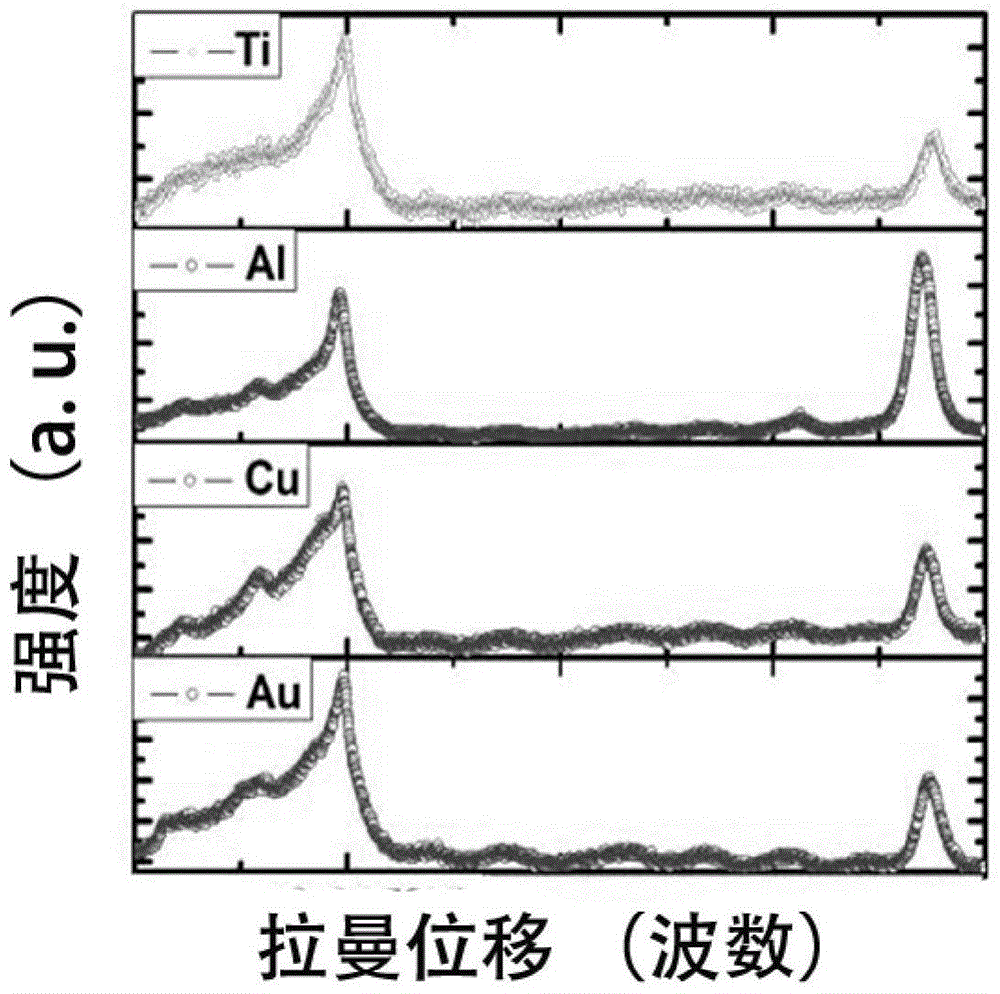

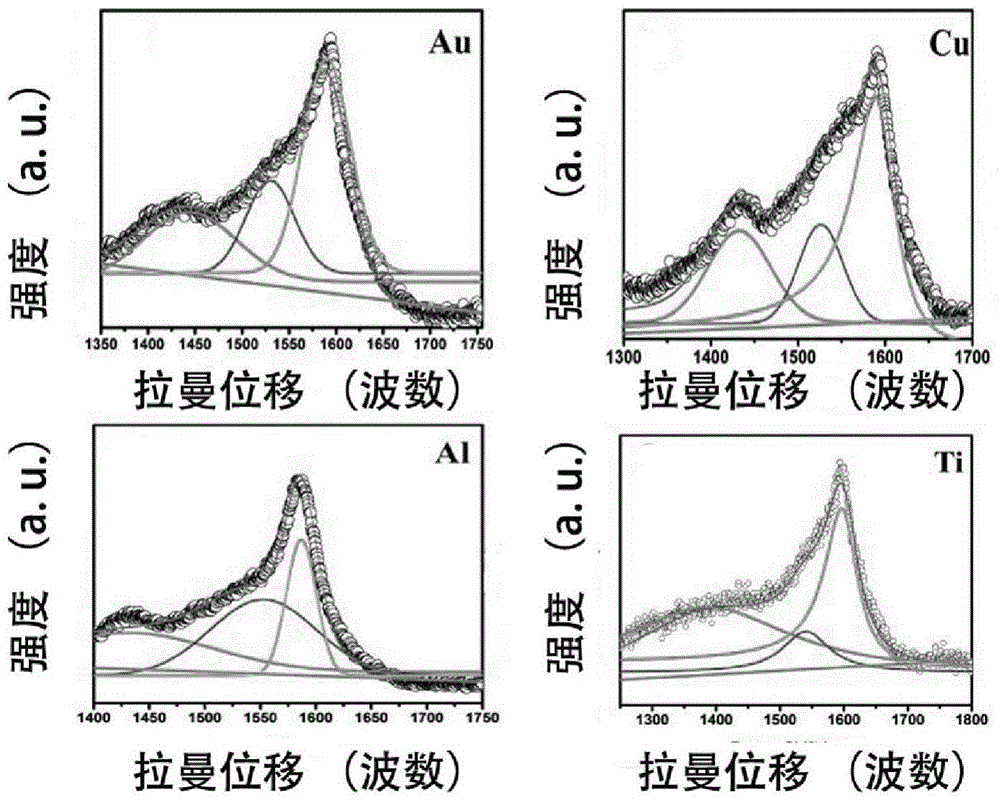

[0038] Put the clean copper sheet into the chemical vapor deposition furnace that has been vacuumed, and feed the hydrogen gas with a flow rate of 40 standard milliliters per minute. After the chemical vapor deposition furnace is heated up to 1000 degrees Celsius, the flow rate is 60 standard milliliters per minute. Minutes of methane gas, after 15 minutes, turn off the methane gas, cool down the chemical vapor deposition furnace to room temperature, take out the copper sheet, spin-coat polymethyl methacrylate on the copper sheet that is in contact with the methane gas, and then apply the copper After 30 minutes, the thin film suspended on the ferric chloride solution was taken out with a clean silicon wafer, and the thin film on the silicon wafer was washed with acetone to obtain the growth on the silicon wafer. Graphene; then 4 nanometers of gold are deposited on the graphene obtained by magnetron sputtering, and finally the graphene obtained by depositing 4 nanometers of gol...

Embodiment 2

[0040] Put the clean copper sheet into the chemical vapor deposition furnace that has been vacuumed, and feed the hydrogen gas with a flow rate of 40 standard milliliters per minute. After the chemical vapor deposition furnace is heated up to 1000 degrees Celsius, the flow rate is 60 standard milliliters per minute. Minutes of methane gas, after 15 minutes, turn off the methane gas, cool down the chemical vapor deposition furnace to room temperature, take out the copper sheet, spin-coat polymethyl methacrylate on the copper sheet that is in contact with the methane gas, and then apply the copper After 30 minutes, the thin film suspended on the ferric chloride solution was taken out with a clean silicon wafer, and the thin film on the silicon wafer was washed with acetone to obtain the growth on the silicon wafer. Graphene; then 4 nanometers of copper are deposited on the graphene obtained by magnetron sputtering, and finally the graphene obtained by depositing 4 nanometers of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com