Method for preparing polymeric silicic acid polymeric titanium chloride inorganic polymer composite flocculant through copolymerization method

An inorganic polymer and composite flocculant technology, applied in the field of environment and chemistry, can solve the problems of effluent pH drop, short storage time, affecting effluent treatment and subsequent utilization, etc., to improve effluent pH, enhance storage time, and avoid stability Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

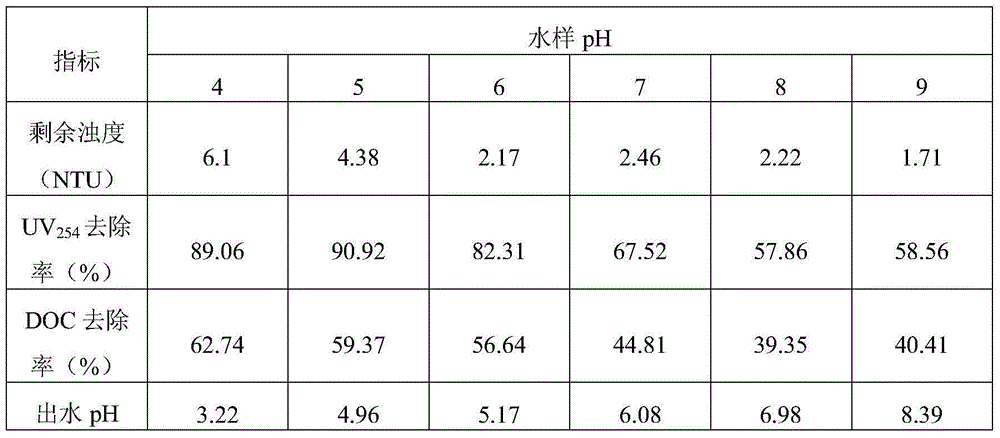

[0033] (1) Weigh 13.6692g Na 2 SiO 3 9H 2 Dissolve the O solid in about 0 mL of water, add it dropwise to 0.5 mol concentration of dilute hydrochloric acid, adjust the pH to always be less than 2 with 0.5 mol / L dilute hydrochloric acid, and control the final pH to 1.5, and after aging for 2 hours, set the volume to 250mL, get 0.192375mol / L (as SiO 2 meter) of polymeric silicic acid solution;

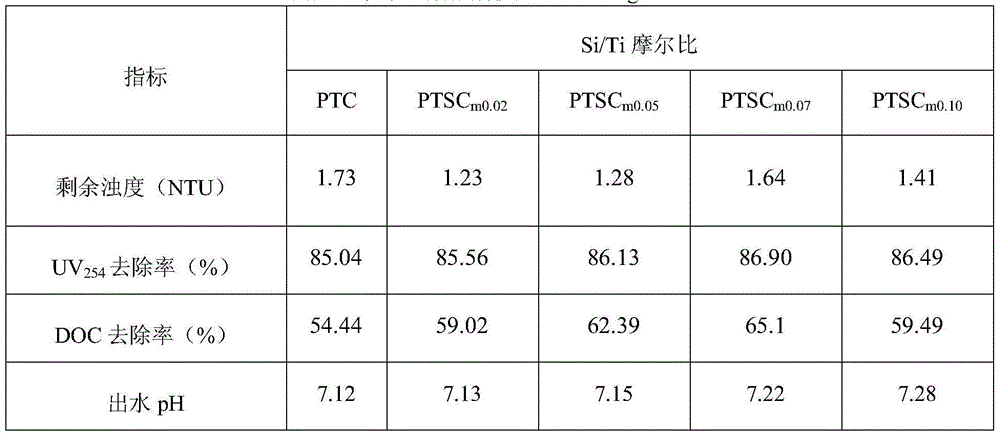

[0034] (2) Measure four parts of 20% titanium tetrachloride solution, each part is 20mL, place them in a magnetic stirrer and stir respectively, and add the prepared fresh poly Silicic acid solution, stirred for 0.5h.

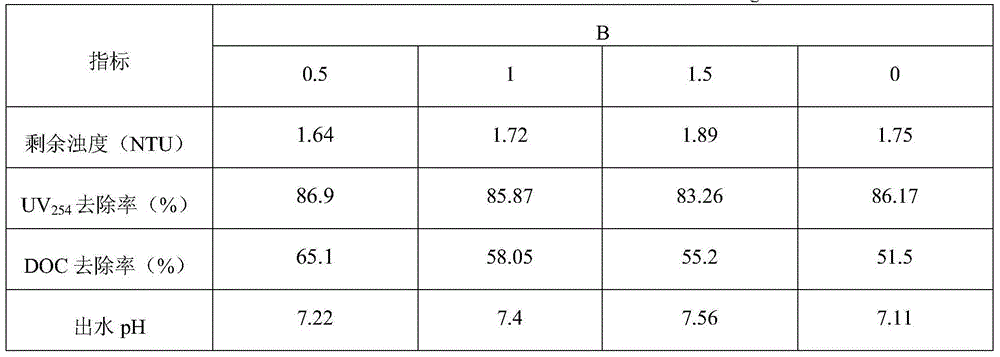

[0035] (3) Divide the mixed solution of different Si / Ti in step (2) into four parts, add the NaOH solution with a concentration of 10wt% dropwise at a rate of 0.3ml / min until the degree of alkalinity is 0.5, 1.0, 1.5 , 0.0 (for comparison), after the dropwise addition, continue to stir for 1h until the solution is colorless and transparent, and the polymeric silicic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com