Waste catalyst mud water dehydration treatment equipment and waste catalyst mud water dehydration treatment method

A waste catalyst and treatment equipment technology, which is applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problems of high cost and poor treatment effect of waste catalyst muddy water, etc. Achieve the effects of small footprint, clean production waste reduction treatment, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

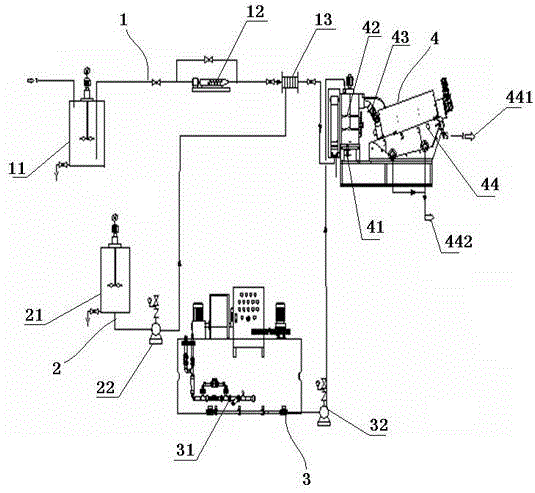

[0039] Such as figure 1 As shown, a waste catalyst sludge dehydration treatment equipment includes a sludge conveying device 1, a complexing agent dosing device 2, a flocculant dosing device 3 and a screw stacking dehydration device 4, and the complexing agent dosing device includes a complexing agent dosing device Mixture preparation tank 21 and complexing agent dosing pump 22, the flocculant dosing device includes a flocculant automatic foaming device 31 and a flocculant dosing pump 32, and the screw stacking dehydration device includes a flocculation mixing tank 41, a stirring Device 42, delivery device 43 and screw stacker main body 44, the sludge conveying device includes an intermediate stirring tank 11, a sludge conveying pump 12 and a pipeline mixer 13, and the waste catalyst muddy water from the bottom of the waste water clarification tank is discharged into the The intermediate stirring tank, after being stirred by the intermediate stirring tank, is fed into the pipe...

Embodiment 2

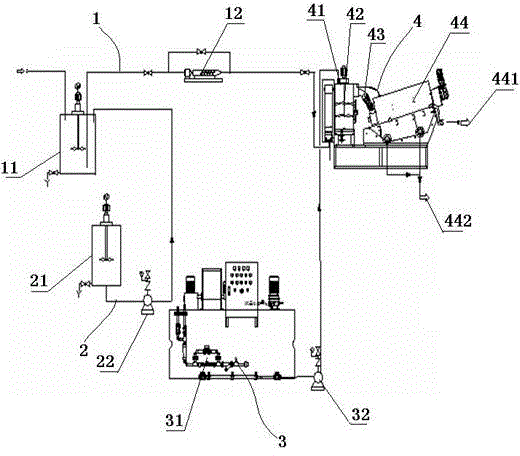

[0057] Such as figure 2 As shown, a waste catalyst sludge dehydration treatment equipment includes a sludge conveying device 1, a complexing agent dosing device 2, a flocculant dosing device 3 and a screw stacking dehydration device 4, and the complexing agent dosing device includes a complexing agent dosing device Mixture preparation tank 21 and complexing agent dosing pump 22, the flocculant dosing device includes a flocculant automatic foaming device 31 and a flocculant dosing pump 32, and the screw stacking dehydration device includes a flocculation mixing tank 41, a stirring Device 42, delivery device 43 and screw stacker main body 44, the sludge conveying device includes an intermediate stirring tank 11 and a sludge conveying pump 12, the waste catalyst muddy water from the bottom of the clarification tank is discharged into the intermediate stirring tank, and network The mixture dosing pump feeds the compounded and screened complexing agent in the complexing agent prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com