Ultra-low-loss lithium magnesium titanate microwave dielectric ceramic material and preparation method thereof

A technology of microwave dielectric ceramics and magnesium lithium titanate, which is applied in the field of electronic information materials and their devices, can solve the problems of increasing the dielectric loss of materials and being difficult to use, and achieves the effects of low cost, simple preparation method, and abundant raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

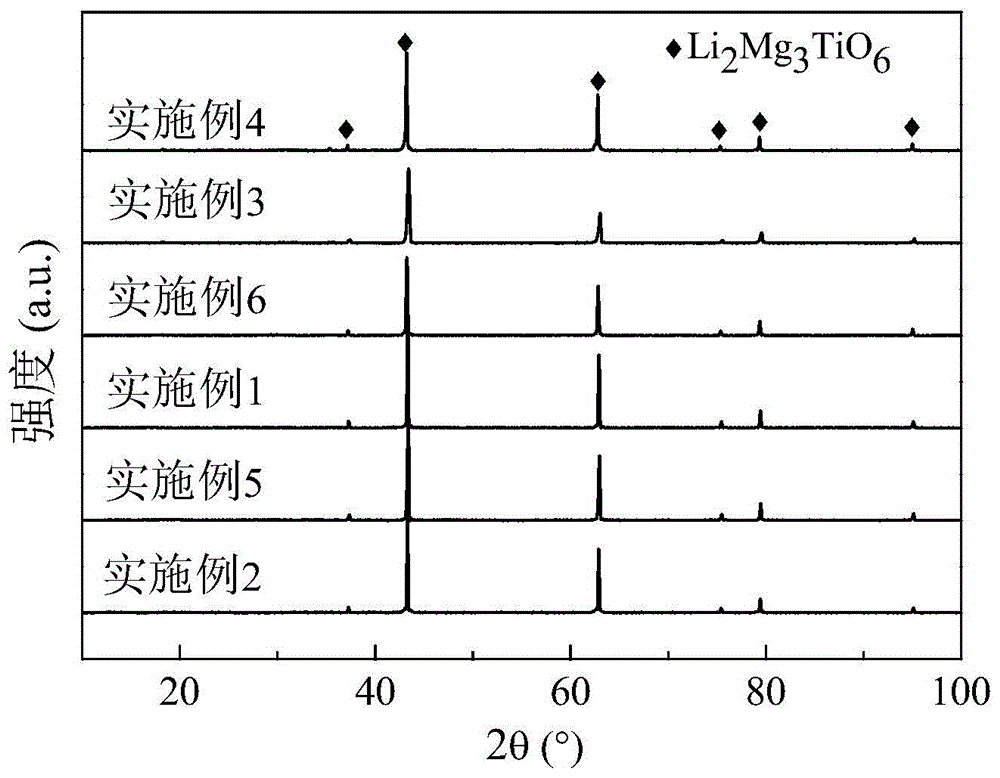

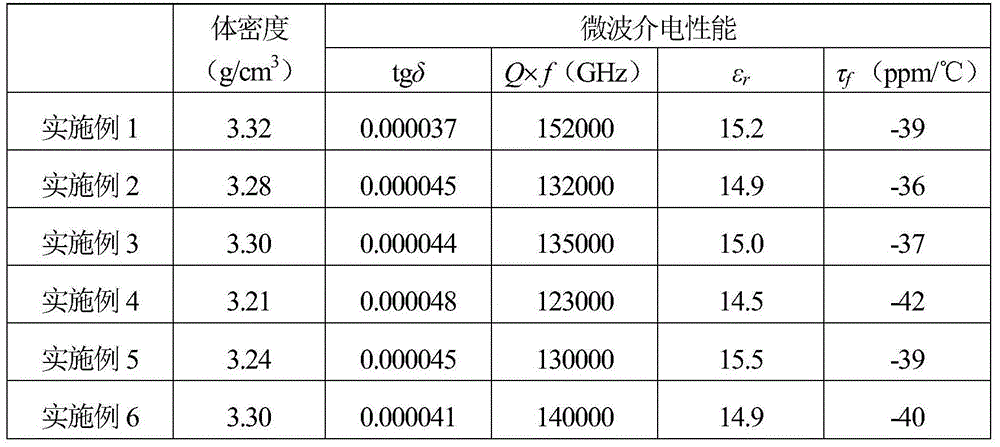

Examples

Embodiment 1

[0023] 1. Mixing

[0024] According to Li 2 Mg 3 TiO 6 The stoichiometric ratio, weigh the Li 2 CO 3 Powder 3.268g, MgO powder 5.243g, TiO 2 Powder 3.462g, the raw material and zirconia balls, absolute ethanol are packed in the ball mill tank with the mass ratio of 1:2:2, 360 rev / min fully mixed ball mill for 8 hours, and dried at 80~100°C for 12 hours.

[0025] 2. Pre-burning

[0026] Put the dried mixture in step 1 into an alumina crucible, raise the temperature to 1000°C at a heating rate of 2°C / min, and pre-fire at a constant temperature for 4 hours to prepare calcined powder.

[0027] 3. Secondary mixing

[0028] Put calcined powder, zirconia balls, and absolute ethanol in a mass ratio of 1:2:2 into a ball mill jar, mix thoroughly and ball mill for 8 hours, and dry at 80-100°C for 12 hours.

[0029] 4. Granulation and molding

[0030] Add its mass fraction to the calcined powder after step 3 drying and be 5% polyvinyl alcohol aqueous solution to granulate, cross ...

Embodiment 2

[0034] In Step 5 of Example 1, the cylindrical green body was sintered at 1260° C. for 6 hours, and other steps were the same as in Example 1 to obtain an ultra-low loss magnesium lithium titanate microwave dielectric ceramic material.

Embodiment 3

[0036] In Step 5 of Example 1, the cylindrical green body was sintered at 1300° C. for 6 hours, and other steps were the same as in Example 1 to obtain an ultra-low loss magnesium lithium titanate microwave dielectric ceramic material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com