Environment-friendly composite textile finishing agent and preparation method thereof

A textile finishing, environmentally friendly technology, applied in textiles, papermaking, fiber processing, etc., can solve problems such as environmental damage, and achieve the effect of improving antibacterial properties and improving wrinkle resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

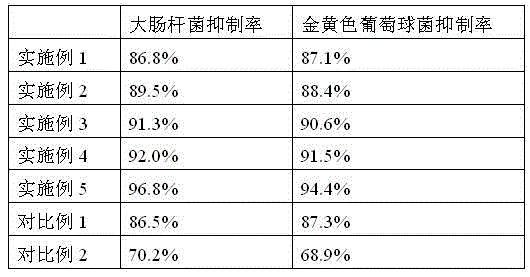

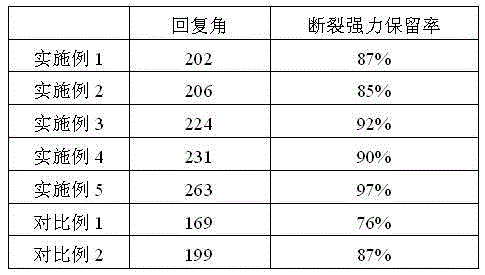

Examples

Embodiment 1

[0046] Step 1: Take water and 1,4-butanediol separately, and mechanically stir the water and 1,4-butanediol until uniform; Step 2: Heat to 50°C, then add xylitol anhydride monostearate, succinate Sodium dioctyl sulfonate, lauryltrimethylammonium chloride, mechanically stirred until uniformly mixed; step 3: finally add almond water extract, chitosan, Burnet 40wt% ethanol water extract, cattail Yellow ethanol extract, then stir until uniform, after stirring evenly, xylitol anhydride monostearate in the finishing solution is 5wt%, dioctyl sodium succinate sulfonate is 3wt%, lauryl trimethyl chloride Ammonium is 3.5wt%, almond water extract is 7wt%, chitosan is 8wt%, Burnet 40wt% ethanol water extract is 9wt%, Pollen ethanol extract is 8wt%, 1,4-butanediol is 12wt%, the balance being water.

Embodiment 2

[0048] Step 1: Take water and 1,4-butanediol separately, and mechanically stir the water and 1,4-butanediol until uniform; Step 2: Heat to 50°C, then add xylitol anhydride monostearate, succinate Sodium dioctyl sulfonate, lauryltrimethylammonium chloride, mechanically stirred until uniformly mixed; step 3: finally add almond water extract, chitosan, Burnet 40wt% ethanol water extract, cattail Yellow ethanol extract, then stirred until uniform, after stirring evenly, xylitol anhydride monostearate in the finishing solution was 2.5wt%, dioctyl sodium succinate sulfonate was 6wt%, dodecyl trimethyl chloride Ammonium chloride 5.5wt%, almond water extract 4wt%, chitosan 4wt%, Burnet 40wt% ethanol water extract 5wt%, Puhuang ethanol extract 3wt%, 1,4-butanediol It is 6wt%, and the balance is water.

Embodiment 3

[0050] Step 1: Take water and 1,4-butanediol separately, and mechanically stir the water and 1,4-butanediol until uniform; Step 2: Heat to 50°C, then add xylitol anhydride monostearate, succinate Sodium dioctyl sulfonate, lauryltrimethylammonium chloride, mechanically stirred until uniformly mixed; step 3: finally add almond water extract, chitosan, Burnet 40wt% ethanol water extract, cattail Yellow ethanol extract, then stir until uniform, and after stirring evenly, xylitol anhydride monostearate in the finishing liquid is 4.5wt%, dioctyl sodium succinate sulfonate is 5wt%, dodecyl trimethyl chloride Ammonium chloride 4.5wt%, almond water extract 6wt%, chitosan 7wt%, Burnet 40wt% ethanol water extract 6wt%, Puhuang ethanol extract 7wt%, 1,4-butanediol It is 10wt%, and the balance is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com