Semiconductor device and method of forming the same

A technology for semiconductors and devices, applied in the field of semiconductor devices and their formation, can solve problems such as insufficient improvement of the operating speed of semiconductor devices, limited improvement of carrier mobility, and reduction of drain induced barrier, etc., to improve electrical performance, increasing carrier mobility, improving the effect of threshold voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] It can be known from the background art that the improvement of carrier mobility of semiconductor devices formed in the prior art is limited, and there are problems such as reduced drain induced barrier and leakage current.

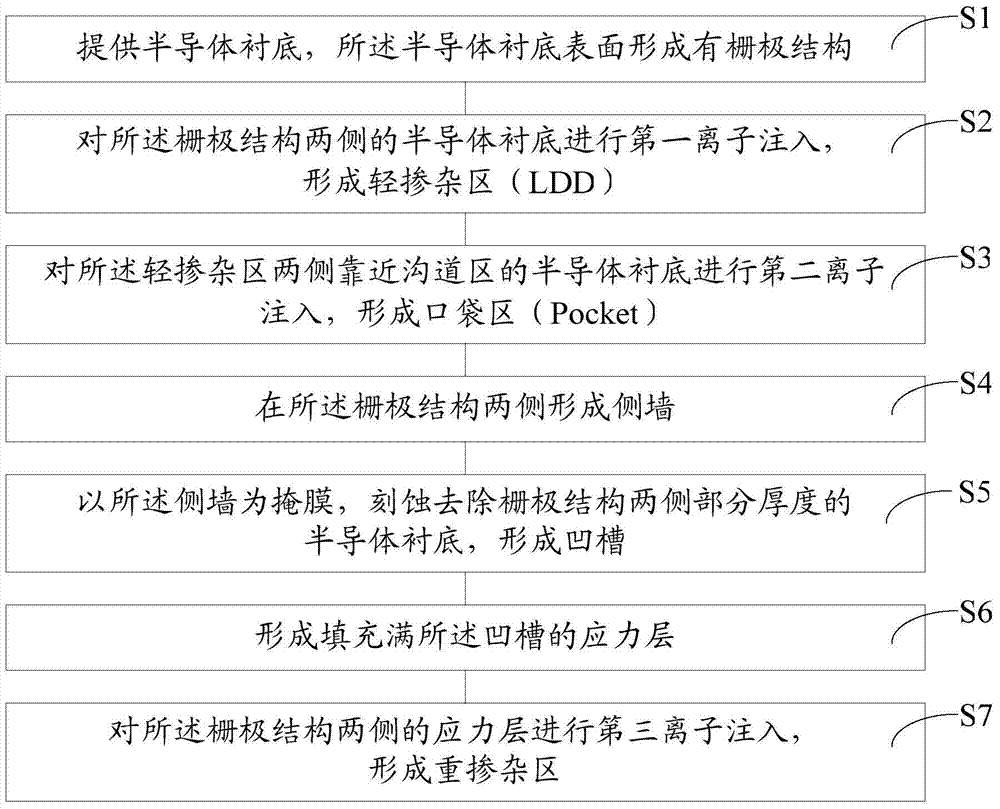

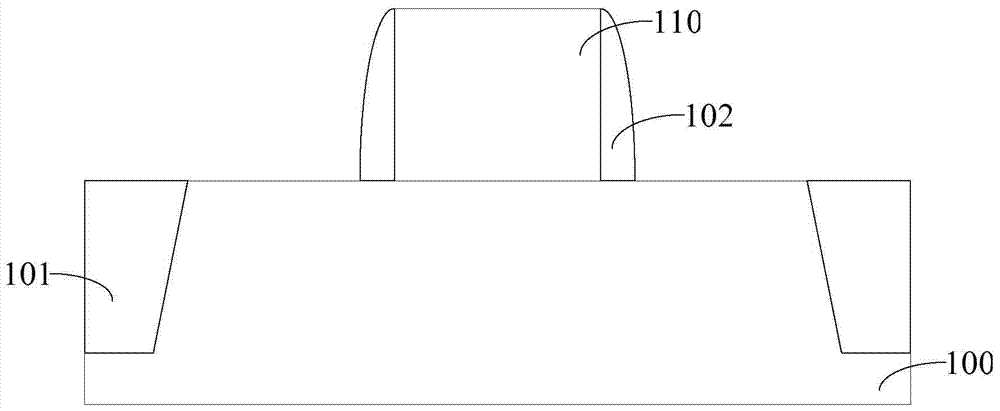

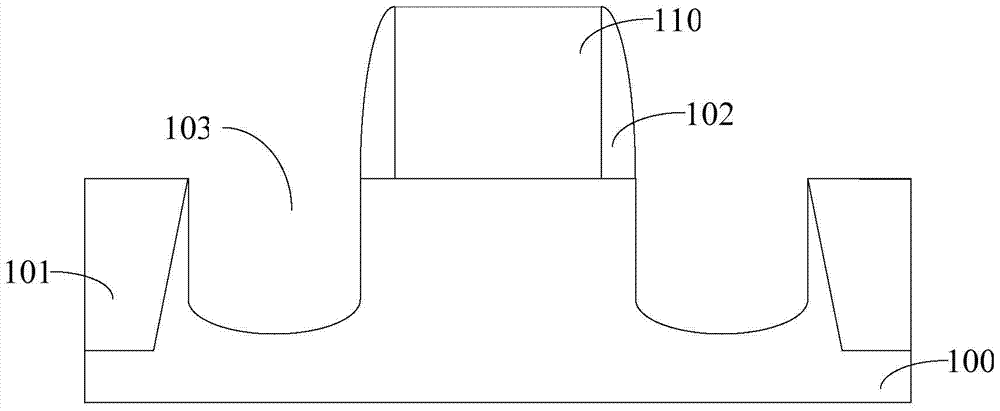

[0037] In order to solve the above-mentioned problems, research has been conducted on the formation process of semiconductor devices. The semiconductor device formation process includes the following steps, please refer to figure 1 : Step S1, providing a semiconductor substrate with a gate structure formed on the surface of the semiconductor substrate; step S2, performing first ion implantation on the semiconductor substrate on both sides of the gate structure to form lightly doped regions (LDD) Step S3, performing a second ion implantation on the semiconductor substrate near the channel region on both sides of the lightly doped region to form a pocket area (Pocket); Step S4, forming sidewalls on both sides of the gate structure; S5. Using the sidewal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com