Two-stage micro/nano aeration and catalytic ozonation wastewater treatment system

A wastewater treatment system, micro-nano aeration technology, applied in the direction of oxidation water/sewage treatment, water/sludge/sewage treatment, water pollutants, etc., can solve the discount of micro-nano aeration effectiveness, has not been fully developed and other issues, to achieve the effect of improving ozone utilization efficiency, reducing consumption, and achieving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

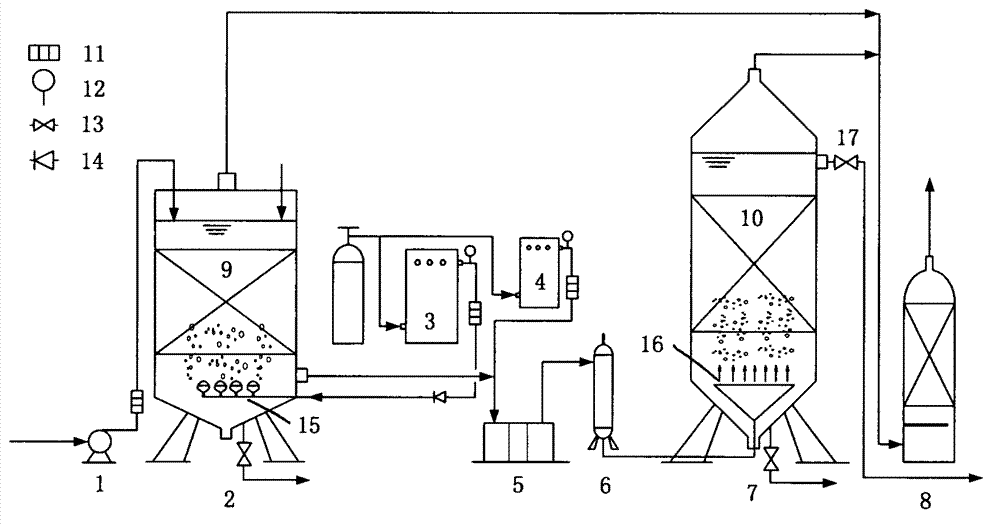

[0033] 1) Turn on the lift pump 1, and the raw water is pumped into the water inlet of the first-stage catalytic reactor 2 through the lift pump 1;

[0034] 2) Turn on the first-stage ozone generator, the raw water enters from top to bottom in the first-stage catalytic reactor 2, and cross-flow mixes with the micron ozone aeration liquid in the first-stage ozone reactor 3, and the effluent of the first-stage catalytic reactor 2 It mainly flows into the micro-nano bubble generator through the water inlet of the micro-nano bubble generator 5, and the bottom of the primary catalytic reactor 2 is provided with a sewage outlet for regular backwashing and sewage discharge;

[0035] 3) Turn on the ozone generator 7 and the micro-nano bubble generator 5. The micro-nano bubble generator 5 fully mixes the effluent in the primary catalytic reactor with the ozone generated by the secondary ozone generator, and generates a large amount of ozone micro-nano bubbles. The gas-water mixture flows...

Embodiment 2

[0044] 1) Turn on the lift pump 1, and the raw water is pumped into the water inlet of the first-stage catalytic reactor 2 through the lift pump 1;

[0045] 2) Turn on the first-stage ozone generator, the raw water enters from top to bottom in the first-stage catalytic reactor 2, and cross-flow mixes with the micron ozone aeration liquid in the first-stage ozone reactor 3, and the effluent of the first-stage catalytic reactor 2 It mainly flows into the micro-nano bubble generator through the water inlet of the micro-nano bubble generator 5, and the bottom of the primary catalytic reactor 2 is provided with a sewage outlet for regular backwashing and sewage discharge;

[0046] 3) Turn on the ozone generator 7 and the micro-nano bubble generator 5. The micro-nano bubble generator 5 fully mixes the effluent in the primary catalytic reactor with the ozone generated by the secondary ozone generator, and generates a large amount of ozone micro-nano bubbles. The gas-water mixture flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com