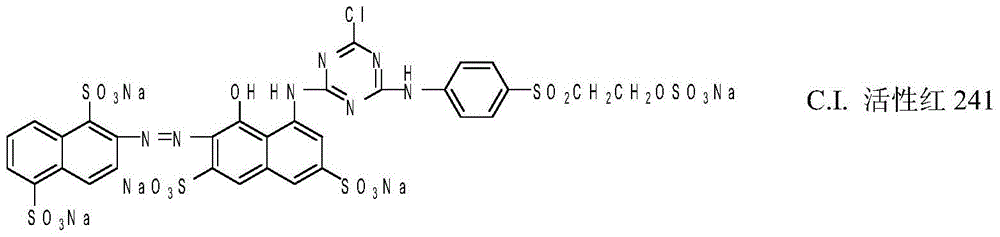

A kind of red reactive dye and its application

A technology of reactive dyes and reactive red dyes, applied in the field of fine chemicals, can solve the problems affecting the development of polyamide fibers, the fixation rate is only 70%, and the environmental pollution, etc., and achieves excellent color fastness, high color fastness, and excellent fastness. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

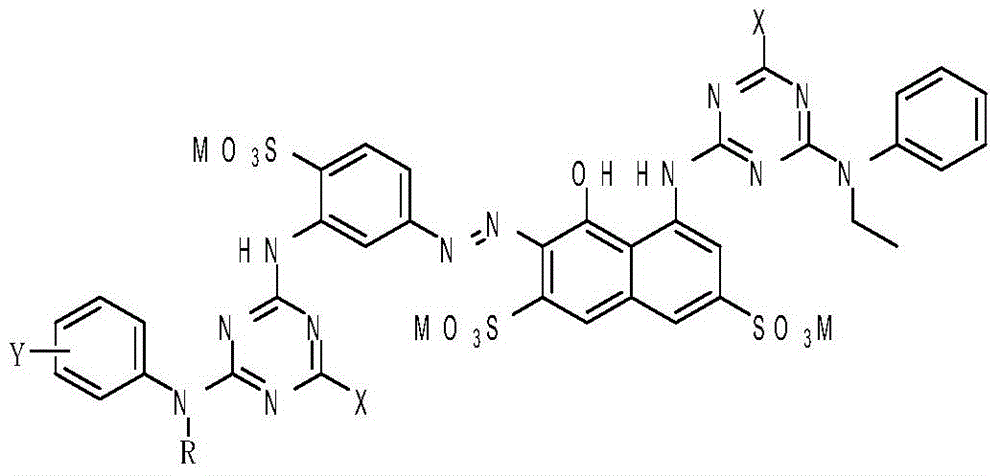

Method used

Image

Examples

Embodiment 1

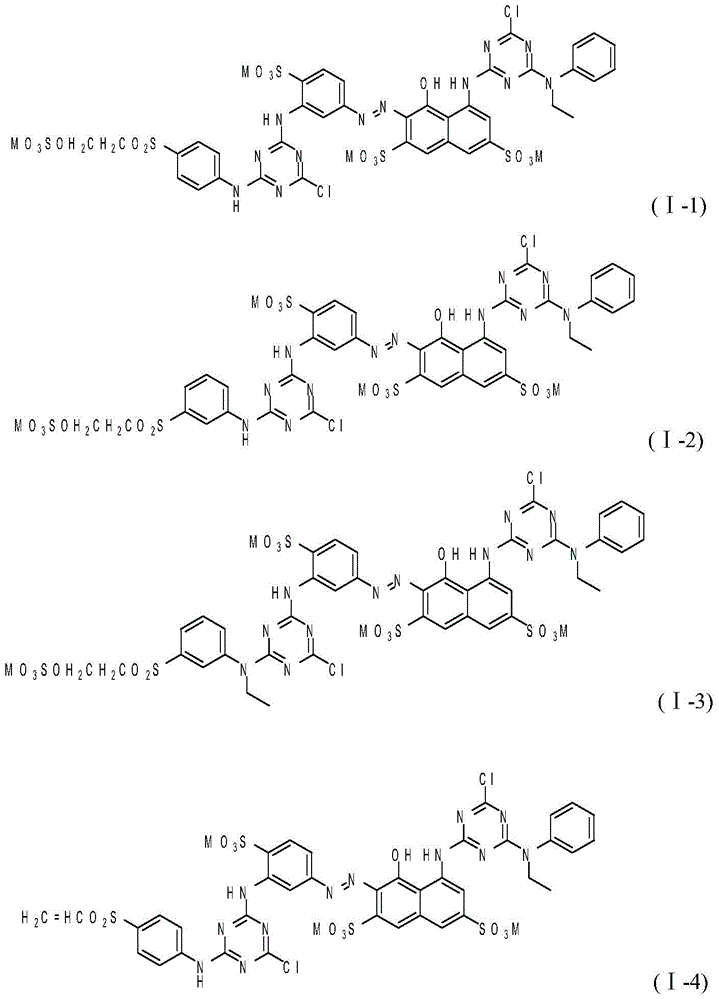

[0046] Prepare the following dyes:

[0047]

[0048] a) Primary condensation reaction of cyanuric chloride and H acid

[0049] Weigh 1.88 parts of cyanuric chloride, add 18 parts of water and crushed ice, and beat at 0-5°C for 30 minutes. At the same time, weigh 3.41 parts of H acid in 15 parts of water, adjust the pH to 6-7 with sodium carbonate, and dissolve it completely. After the beating is finished, drop the above-mentioned H acid solution into the cyanuric chloride suspension within 1 hour. After the dropwise addition, adjust the pH value of the reaction to 2-3 with sodium carbonate, and react until there is no free H acid, which is the end point.

[0050] b) Secondary condensation reaction

[0051] Weigh 1.21 parts of N-ethylaniline and add it to the above-mentioned primary condensation reaction solution, and at the same time raise the temperature to 35-40°C, adjust the pH value to 5-5.5 with sodium carbonate, and keep the temperature and pH value for about 4 hou...

Embodiment 2、3

[0063] In a method similar to that described in Example 1, respectively select m-beta-hydroxyethylsulfone aniline sulfate and 3-N-ethylaminophenyl (2-sulfonic acid oxygen ethyl) sulfone as raw materials to replace p-beta- Ethylsulfone aniline sulfate, dye 2 and dye 3 can be obtained as shown below:

[0064]

Embodiment 4

[0066] Prepare the following dyes:

[0067]

[0068] The condensation solution obtained in e) of Example 1, that is, the dye (1) solution, was adjusted to pH=10 with sodium hydroxide, and the temperature was kept at 40-50°C for reaction, and the reaction was followed by HPLC until the condensate disappeared. Then adjust the pH=7.0 with 30% hydrochloric acid solution, and dry directly to obtain 17.5 parts of the red reactive dye product of the above-mentioned dye (4).

[0069] Dyeing the above-mentioned dye (4) on polyamide fibers yields a bright red color with a color absorption rate of 98.1% and a color fixation rate of 92.3%.

[0070] The synthesized dye (4) compound was subjected to high resolution mass spectrometry, the calculated molecular weight of the dye was M=1044.04, and the measured molecular weight of the dye was 1044.10. The calculated value is [M-1] / 1=1043.04, and the measured value is 1043.10; the calculated value is [M-2] / 2=521.02, and the measured value is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com