Film resistor material, film resistor and preparation method of film resistor

A thin-film resistor, conductive support technology, used in resistor manufacturing, resistors, non-adjustable metal resistors, etc., can solve problems such as low sheet resistance, and achieve high square resistance value, low resistance temperature coefficient, and high temperature stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a method for preparing a thin-film resistor, comprising: depositing the thin-film resistor material described in the above technical solution on a support by physical vapor deposition to obtain a thin-film resistor.

[0037]In the present invention, thin-film resistor materials are deposited on a support to prepare thin-film resistors by physical vapor deposition; said physical vapor deposition includes but not limited to vacuum evaporation, magnetron sputtering, arc plasma plating, ion plating and molecular Beam epitaxy is preferably one of vacuum evaporation, magnetron sputtering, and ion plating; more preferably one of vacuum evaporation and magnetron sputtering. The support body is a conductive support body or an insulating support body. The present invention is not limited to the conductive support body. A conductive support body well-known to those skilled in the art can be used, preferably copper foil; the insulating support bod...

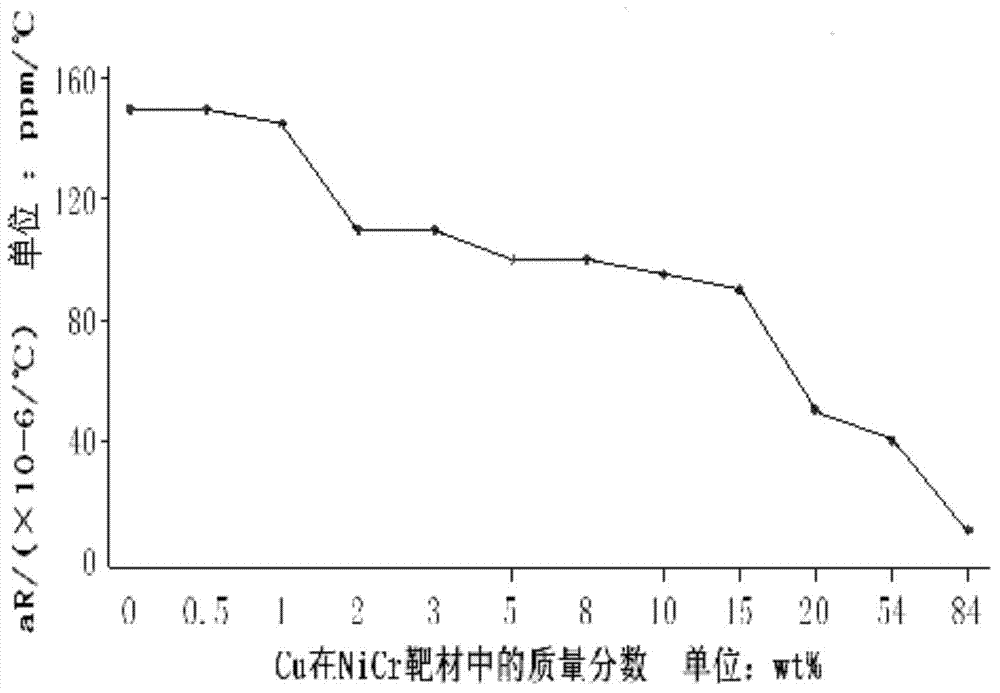

Embodiment 1~11

[0044] Add 0.5%, 1%, 2%, 3%, 5%, 8%, 10%, 15%, 20%, and 54% of the mass percentage of the target to the mixture of Ni and Cr with a mass ratio of 4:1 , 84% Cu to prepare the target material, vacuumize to 1.5×10 after starting up -6 After mbar, adjust the argon flow to make the vacuum in the chamber 1.7×10 -2 mbar, constant current sputtering, current 20A, voltage 300-400V, sputtering time 5min, annealing under nitrogen condition at 300°C after sputtering to prepare thin film resistors. The resistance temperature variation coefficients of the prepared thin film resistors were measured respectively, and the results are as follows: figure 1 as shown, figure 1 The resistance temperature variation coefficient figure of the thin film resistance that is prepared for embodiment 1~11 of the present invention and comparative example 1; figure 1 It can be seen that, compared with the thin-film resistor without adding copper, the addition of copper has a certain effect on reducing the ...

Embodiment 12

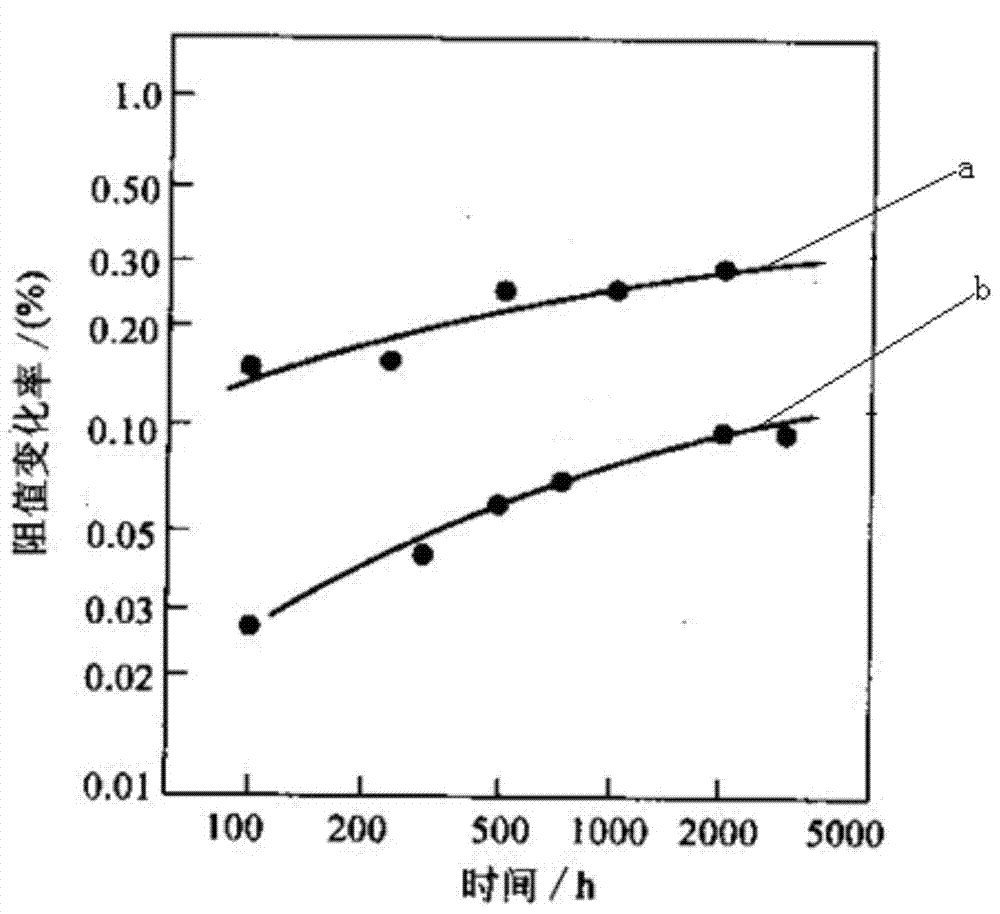

[0048] Under the condition of 150°C, the thin-film resistors composed of Ni, Cr, and Cu with a mass ratio of 78:20:2 were placed for 100-5000 hours, and the change rate of the resistance value was measured. The results are as follows: figure 2 as shown, figure 2 The stability curves of the thin-film resistors provided by Example 12 of the present invention and Comparative Example 2, wherein curve b is the stability curves of the thin-film resistors provided by Example 12 of the present invention; as can be seen from curve b, the embodiment of the present invention 12 provides high stability of thin film resistors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com