X-ray flat panel detector and preparation method thereof as well as white insulation material

A technology of flat-panel detectors and insulating materials, applied in X/γ/cosmic radiation measurement, radiation measurement, radiation control devices, etc., can solve the problems of reducing photodiode conversion efficiency, photoelectric conversion efficiency decline, and light-induced degradation. Achieve high quantum detection efficiency and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

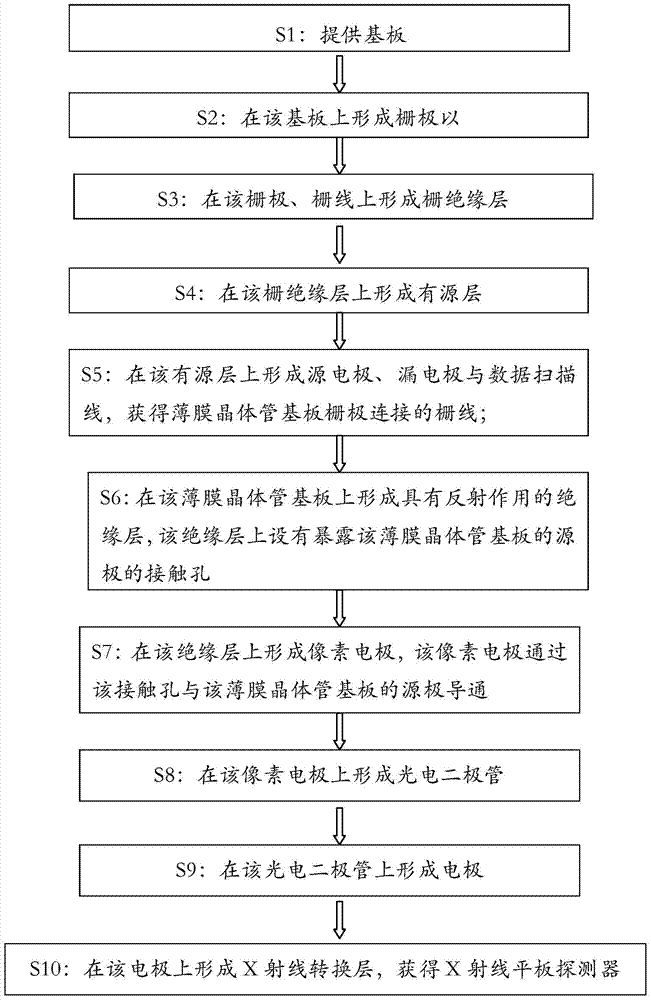

[0080] Prepare X-ray flat panel detectors, such as figure 2 shown, including the following steps

[0081] S1: Provide the substrate;

[0082] Wherein, the substrate may be a glass plate, a quartz plate or the like.

[0083] S2: forming a gate and a gate line connected to the gate on the substrate;

[0084] A thin film of a gate line layer is deposited on the substrate, and a gate and a gate line connected to the gate are formed through a patterning process.

[0085] Specifically, at first, a gate line layer film can be deposited on the substrate by sputtering or thermal evaporation, and the gate line layer film can use metals such as Cr, W, Ti, Ta, Mo, Al, Cu and alloys thereof, and then A mask plate is used to etch the gate line layer film through a patterning process, and a gate and a gate line connected to the gate are formed on the substrate.

[0086] The patterning process usually includes processes such as substrate cleaning, film formation, photoresist coating, exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com