Ordered gas diffusion electrode, and production method and application thereof

A gas diffusion electrode and gas diffusion layer technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of large mass transfer resistance and affect the overall performance of the battery, achieve high utilization rate, improve the oxygen reduction capacity per unit mass, Practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Preparation of gas diffusion layer:

[0038] Soak Toray carbon paper in 20% PTFE aqueous solution, take it out and air dry after fully soaking, and weigh it. Repeat the above steps until the PTFE load is about 15%. Mix Vulcan XC-72 carbon powder with 10% PTFE aqueous solution relative to the total mass, dilute with ethanol, disperse under ultrasonic conditions for 20 minutes, and stir evenly. The above-mentioned hydrophobized carbon paper was placed on a glass plate and fixed, and the above-mentioned slurry was scraped on the surface of the carbon paper and weighed until the carbon powder loading was 1 mg cm -2 , that is, the gas diffusion layer is obtained.

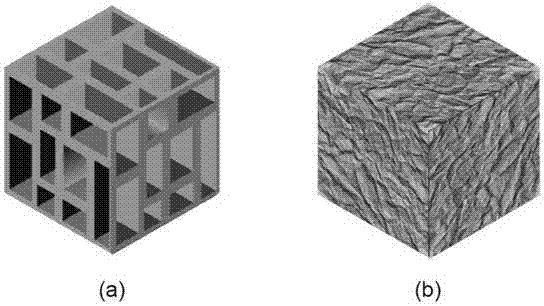

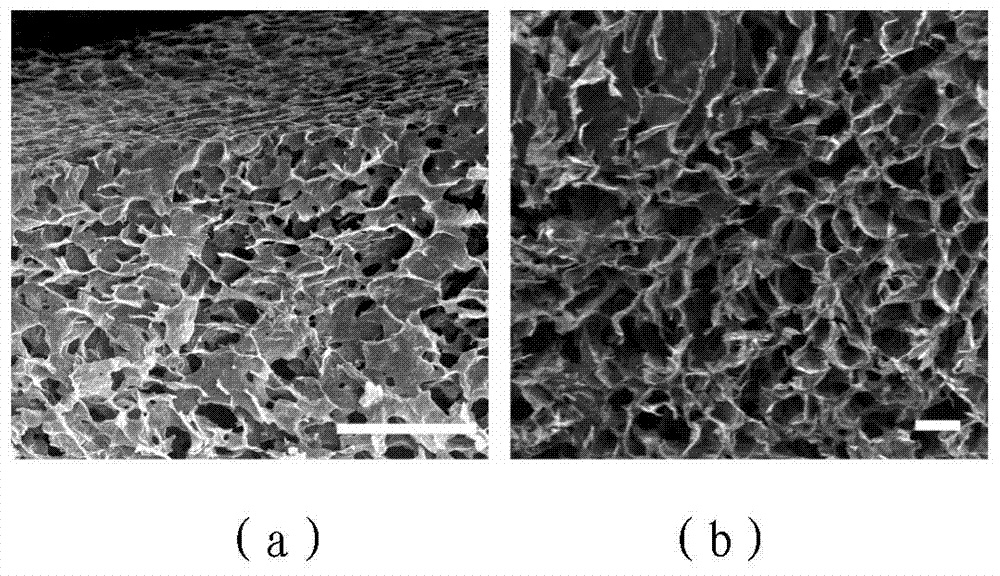

[0039] 2) Preparation of gas diffusion electrode with porous skeleton structure:

[0040] a. Preparation of composite precursor slurry with porous framework structure

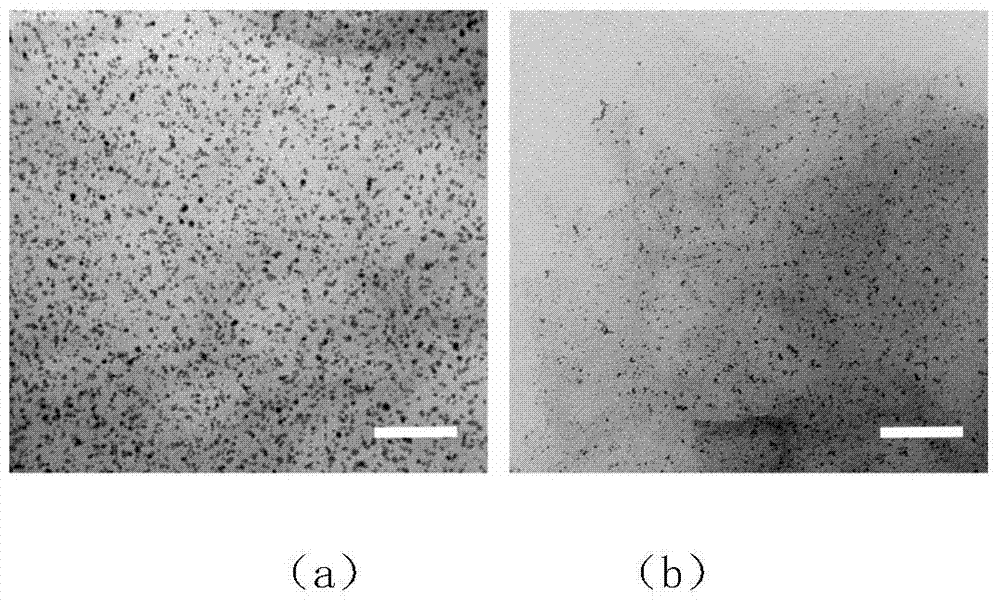

[0041] Disperse 50mg of graphite oxide in 100mL of deionized water, and disperse evenly by ultrasonic; add 80mg of dinitrosodiamine platinu...

Embodiment 2

[0045] 1) Preparation of gas diffusion layer:

[0046] Soak Toray carbon paper in 20% PTFE aqueous solution, take it out and air dry after fully soaking, and weigh it. Repeat the above steps until the PTFE load is about 15%. Mix Vulcan XC-72 carbon powder with 10% PTFE aqueous solution relative to the total mass, dilute with ethanol, disperse under ultrasonic conditions for 20 minutes, and stir evenly. The above-mentioned hydrophobized carbon paper was placed on a glass plate and fixed, and the above-mentioned slurry was scraped on the surface of the carbon paper and weighed until the carbon powder loading was 1 mg cm -2 , that is, the gas diffusion layer is obtained.

[0047] 2) Preparation of gas diffusion electrode with porous skeleton structure:

[0048] a. Preparation of composite precursor slurry with porous framework structure

[0049] Disperse 80mg of graphite oxide in 100mL of deionized water, and ultrasonically disperse evenly; add 80mg of dinitrosodiamine platin...

Embodiment 3

[0053] 1) Preparation of gas diffusion layer:

[0054] Soak Toray carbon paper in 20% PTFE aqueous solution, take it out and air dry after fully soaking, and weigh it. Repeat the above steps until the PTFE load is about 15%. Mix Vulcan XC-72 carbon powder with 10% PTFE aqueous solution relative to the total mass, dilute with ethanol, disperse under ultrasonic conditions for 20 minutes, and stir evenly. The above-mentioned hydrophobized carbon paper was placed on a glass plate and fixed, and the above-mentioned slurry was scraped on the surface of the carbon paper and weighed until the carbon powder loading was 1 mg cm -2 , that is, the gas diffusion layer is obtained.

[0055] 2) Preparation of gas diffusion electrode with porous skeleton structure:

[0056] a. Preparation of composite precursor slurry with porous framework structure

[0057] Disperse 100mg of graphite oxide in 100mL of deionized water, and ultrasonically disperse evenly; add 80mg of dinitrosodiamine plati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com