Method for preparing organic modified clay for removing organic pollutants from wastewater

A technology of organic pollutants and clay, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve problems such as application limitations, and achieve the effect of strengthening the distribution of adsorption and enhancing the adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

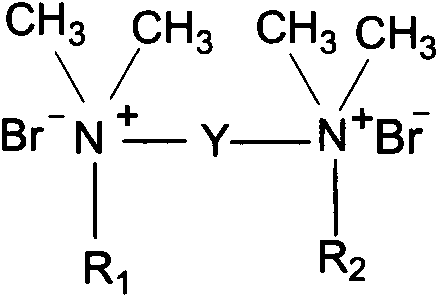

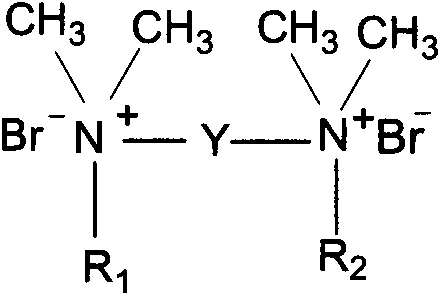

[0015] In a 1000mL beaker, add 10g of montmorillonite dried and crushed through a 20-mesh sieve and 500mL of 0.05mol / L Gemini surfactant (C 12 h 25 N + BrCH 2 ) 2 The solution was magnetically stirred at 60° C. for 18 hours, centrifuged to obtain a solid product, dried at 80° C., ground, and passed through a 100-mesh sieve to obtain an organically modified montmorillonite.

[0016] Will make (C 12 h 25 N + BrCH 2 ) 2 Add 0.1 g of modified organic montmorillonite to 200 mL of 100 mg / L phenol solution and mix. The temperature was 25°C and the rotational speed was 190r / min. The adsorption was oscillating for 6h, centrifuged, and the supernatant was taken to measure the remaining phenol concentration by UV-Vis spectrophotometry. The calculated phenol removal rate was 81%.

Embodiment 2

[0018] In a 500mL beaker, add 5g of bentonite that was dried and crushed through a 50-mesh sieve and 300mL of 0.005mol / L Gemini surfactant (C 16 h 33 N + BrCH 2 CHOH) 2 The solution was magnetically stirred at 80°C for 24 hours, centrifuged to obtain a solid product, dried at 80°C, ground, and passed through a 100-mesh sieve to obtain an organically modified bentonite.

[0019] Will make (C 16 h 33 N + BrCH 2 CHOH) 2 Add 0.2 g of modified organic bentonite to 200 mL of 200 mg / L phenol solution and mix. The temperature was 25°C, and the rotation speed was 190r / min. The adsorption was shaken for 6h, and the supernatant was taken to measure the remaining phenol concentration by UV-Vis spectrophotometry. The calculated phenol removal rate was 86%.

Embodiment 3

[0021] In a 1000mL beaker, add 5g of montmorillonite dried and crushed through a 100-mesh sieve and 500mL of 0.0001mol / L Gemini surfactant (C 18 h 37 N + BrCHOH) 2 The solution was magnetically stirred at 70°C for 36 hours, centrifuged to obtain a solid product, dried at 80°C, ground, and passed through a 100-mesh sieve to obtain an organically modified montmorillonite.

[0022] Will make (C 16 h 33 N + BrCH 2 CHOH) 2 Add 0.3 g of modified organic montmorillonite to 200 mL of 200 mg / L phenol solution and mix. The temperature was 25°C and the rotational speed was 190r / min. The adsorption was oscillated for 6h, centrifuged, and the supernatant was taken to measure the remaining phenol concentration by UV-Vis spectrophotometry. The calculated phenol removal rate was 88%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com