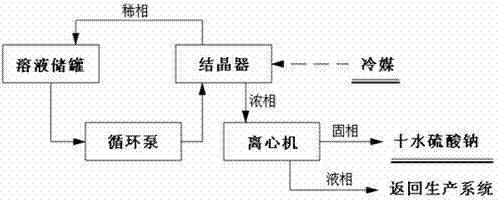

Method and device for crystallizing lead plaster desulphurization by-product sodium sulfate based on localized cooling and rapid crystal precipitation

A desulfurization by-product, cooling crystallization technology, applied in chemical instruments and methods, alkali metal sulfite/sulfite, alkali metal compounds, etc., can solve product scaling and scarring, reduce evaporation efficiency, equipment pipeline blockage, etc. problems, achieve stable operation, overcome high energy consumption, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

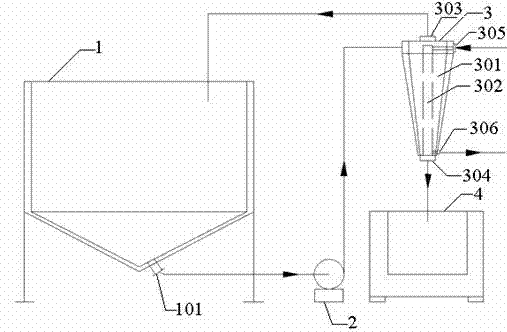

[0023] Such as figure 2 As shown, inject 400kg of sodium sulfate solution (mass fraction: 25%) into the solution storage tank 1 (Φ0.6m, height 0.8m), the temperature of the sodium sulfate solution is 25°C at room temperature, and the refrigeration system is turned on to input refrigerant to the cooling crystallizer 3 , turn on the circulation pump 2, the sodium sulfate solution is pumped into the cooling crystallizer 3 through the outlet 101, the flow rate of the circulation pump 2 is 50L / h, the cooling crystallizer 3 includes a gravity settler 301 and a central column pipe 302, and the refrigerant inlet 305 is adjusted The refrigerant at the outlet 306 of the cooling medium makes the temperature of the dilute phase at the upper outlet 303 of the cooling crystallizer 5°C, and the dilute phase at the upper outlet 303 of the cooling crystallizer returns to the storage tank 1 and brings the refrigerant into the solution in the storage tank 1 to gradually cool down the temperature...

Embodiment 2

[0025] Such as figure 2 As shown, inject 400kg of sodium sulfate solution (mass fraction: 28%) into the solution storage tank 1 (Φ0.6m, height 0.8m), the temperature of the sodium sulfate solution is 20°C, turn on the refrigeration system and input refrigerant to the cooling crystallizer 3, Open circulation pump 2, sodium sulfate solution is pumped in cooling crystallizer 3 through outlet 101, and the flow rate of circulation pump 2 is 50L / h, and cooling crystallizer 3 comprises gravity settler 301 and central column pipe 302, regulates refrigerant inlet 305 and The refrigerant at the refrigerant outlet 306 makes the temperature of the dilute phase at the upper outlet 303 of the cooling crystallizer 0°C, and the dilute phase at the upper outlet 303 of the cooling crystallizer returns to the storage tank 1 and brings the refrigerant into the solution in the storage tank 1 to gradually cool down, and the cooling crystallizer 3 The slurry with 47% dense phase at the bottom enter...

Embodiment 3

[0027] Such as figure 2 As shown, inject 400kg of sodium sulfate solution (mass fraction: 20%) into the solution storage tank 1 (Φ0.6m, height 0.8m), the temperature of the sodium sulfate solution is 25°C at room temperature, and the refrigeration system is turned on to input refrigerant to the cooling crystallizer 3 , turn on the circulation pump 2, the sodium sulfate solution is pumped into the cooling crystallizer 3 through the outlet 101, the flow rate of the circulation pump 2 is 50L / h, the cooling crystallizer 3 includes a gravity settler 301 and a central column pipe 302, and the refrigerant inlet 305 is adjusted The refrigerant at the outlet 306 of the cooling medium makes the temperature of the dilute phase at the upper outlet 303 of the cooling crystallizer 3°C, and the dilute phase at the upper outlet 303 of the cooling crystallizer returns to the storage tank 1 and brings the refrigerant into the solution in the storage tank 1 to gradually cool down the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com