Novel environment-friendly production process of 1-naphthol-4-sulfonic acid

A new process, sulfonic acid technology, applied in the preparation of sulfonic acid, organic chemistry, etc., can solve the problems of difficult separation of isomers, waste of energy and environment, and many by-products, so as to reduce SO2 pollution and resource waste, and save acid resources. , the effect of increasing the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

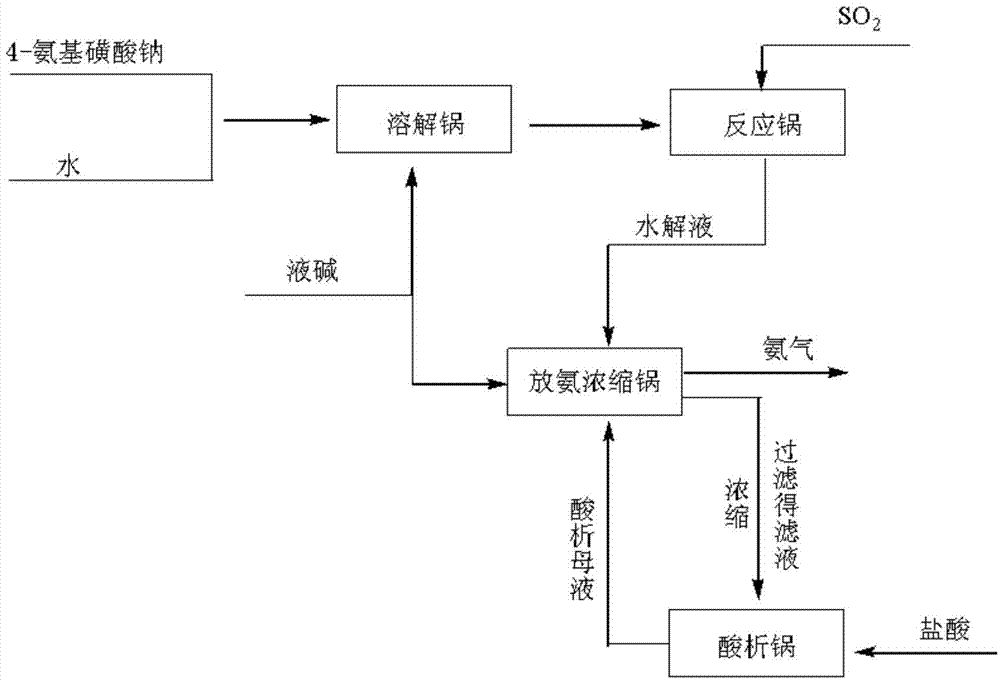

Method used

Image

Examples

Embodiment 1

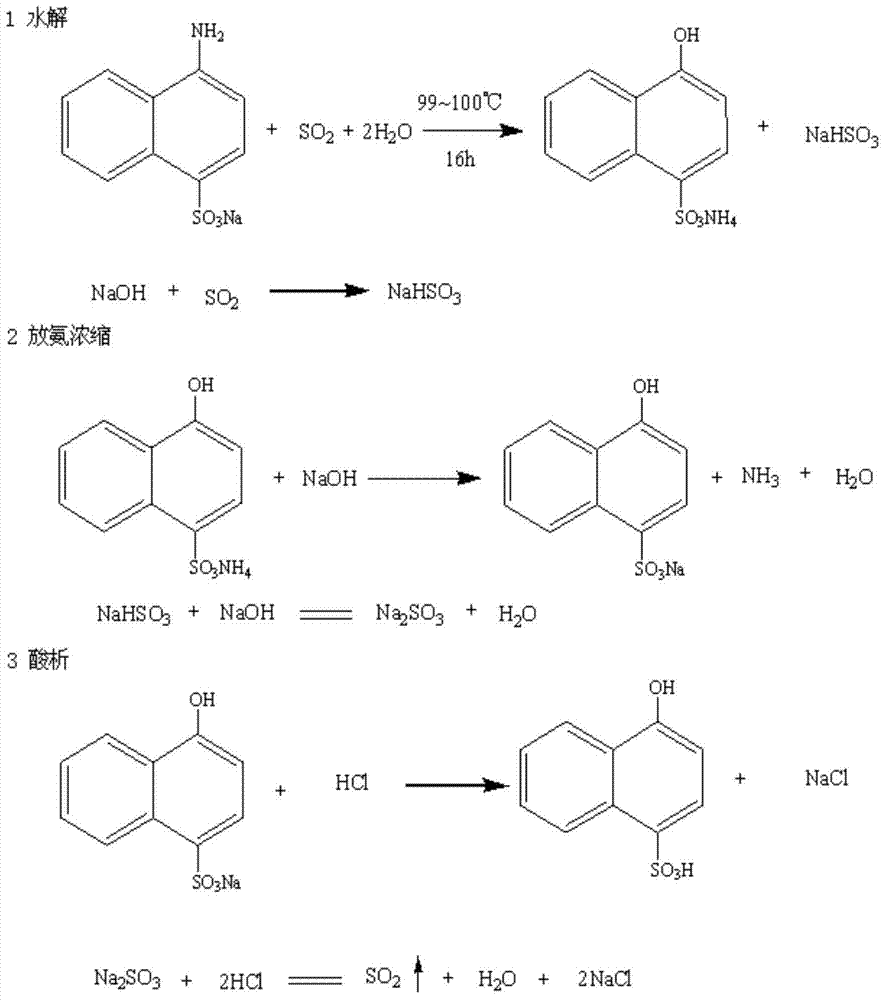

[0025] Add 600kg of sodium 4-sulfamate into the dissolving pot, add 1200kg of water, heat up to 95°C, then add 73.5kg of liquid caustic soda, stir to dissolve completely, then put it into a sealed enamel reaction pot with a volume of 3000L, and heat up to 100°C , feed SO at a flow rate of 10kg / h 2 After 1 hour, samples were taken to determine the end point of the reaction. Then put 450kg of liquid caustic soda with a mass concentration of 40% in the ammonia release concentration pot, heat up to 100°C, press in a certain amount of hydrolyzate to make the pH of the solution reach 12, heat up to 100°C to drive out the ammonia gas, and inject the above A batch of acid analysis of all the mother liquor, concentrated to d = 1.21g / cm 3 , filter to remove impurities. The filtrate was blown dry with steam, poured into an acid analysis kettle, added hydrochloric acid while it was hot until the pH value of the solution was 3, filtered to take the filter cake, blown dry to obtain 391 kg...

Embodiment 2

[0027] Add 600kg of sodium 4-sulfamate into the dissolving pot, add 1200kg of water, heat up to 95°C, then add 73.5kg of liquid caustic soda, stir to dissolve completely, then put it into a sealed enamel reaction pot with a volume of 3000L, and heat up to 100°C , feed SO at a flow rate of 10.5kg / h 2 After 1 hour, samples were taken to determine the end point of the reaction. Then put 450kg of liquid caustic soda with a mass concentration of 40% in the ammonia release concentration pot, heat up to 100°C, press in a certain amount of hydrolyzate to make the pH of the solution reach 12, heat up to 100°C to drive out the ammonia gas, and inject the above A batch of acid analysis of all the mother liquor, concentrated to d = 1.22g / cm 3 , filter to remove impurities. The filtrate was blown dry with steam, poured into an acid analysis kettle, added hydrochloric acid while it was hot until the pH value of the solution was 3, filtered to take the filter cake, blown dry to obtain 395k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com