Method for measuring heavy metals in ink based on partial least squares

A partial least square method, heavy metal technology, applied in the direction of material excitation analysis, etc., can solve the problems of obvious matrix effect, limited application, and influence measurement, so as to improve the prediction accuracy and reduce the effect of parameter fluctuation

Inactive Publication Date: 2015-06-24

NORTHWEST UNIV

View PDF1 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this technology has great disadvantages when measuring liquid samples, such as sputtering, quenching and short life of plasma, which will affect the measurement, and the obvious matrix effect of this technology also limits the application of this technology in liquids

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0019] like figure 1 Shown, a kind of mensuration method of heavy metal in ink based on partial least square method, its steps are as follows:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

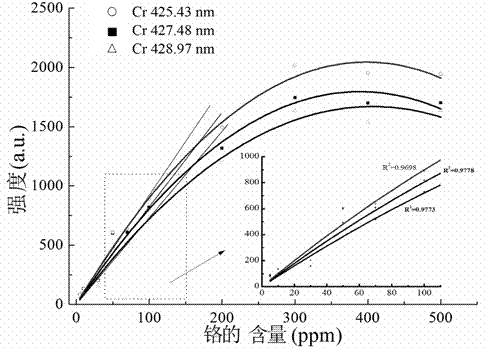

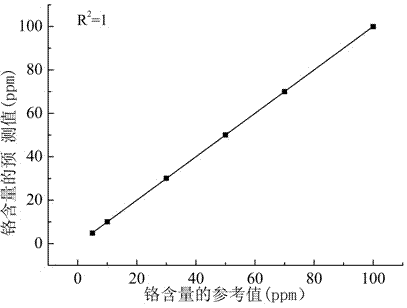

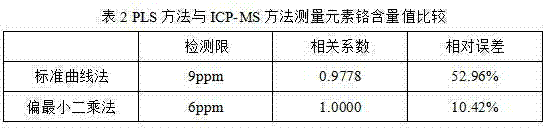

The invention discloses a method for measuring heavy metals in ink based on partial least squares. The method comprises the following steps: at first, attaching ions in a calibration sample to an adsorbent by using zinc oxide as an adsorbent, then detecting the calibration sample with an unknown content by using an LIBS system, and establishing a PLS regression equation of the calibration sample according to an obtained spectral line intensity matrix; and then detecting a sample to be measured and obtaining an LIBS spectrum, substituting the spectral line intensity matrix of the spectrum into the corresponding PLS regression equation to calculate the mass concentrations of elements in the sample to be measured. According to the method, the effective information of the LIBS spectrum is sufficiently utilized, the multiple correlations of the spectral line intensity caused by mutual interference of the elements are overcome, the impact of a matrix effect is reduced, and compared with the traditional single variable calibration method, the method has the advantages of good goodness of fit, strong repeatability and high prediction accuracy.

Description

technical field [0001] The invention relates to a method for quantitatively analyzing heavy metals in ink by combining laser-induced breakdown spectroscopy (LIBS for short) with partial least squares (PLS). Background technique [0002] In the process of collecting samples of plants, geology, and the environment, and in many fields such as the manufacture of electronic circuit boards, batteries, and semiconductor chips, it is often necessary to use marker pens or inks of different colors to mark or label sample specimens and products. The ink or dye in the marker pen writes or prints on the sample or product, and many of these inks or dyes are metal complex dyes, which contain certain metal ions, and these common metals are copper, chromium and cobalt. If care is not taken, these metal ions will remain or infiltrate into samples or products to cause heavy metal pollution and doping. Therefore, it is of great significance to measure the metal ions in these used marking pen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N21/63

Inventor 李华张天龙魏娇

Owner NORTHWEST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com