Bifocal wave zone plate interference microscopic-inspection apparatus for detecting flat mask defect

A technology of bifocal zone plate and detection plane, which is applied in the directions of measuring devices, optical testing flaws/defects, using optical devices, etc., to achieve the effects of reducing quality requirements, improving utilization rate, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

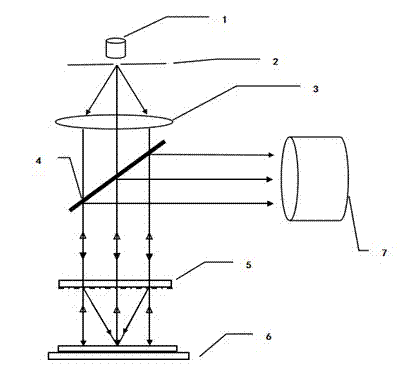

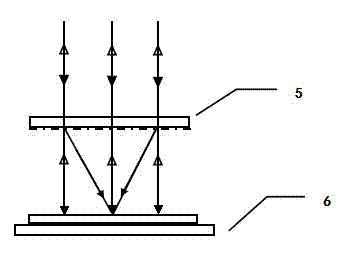

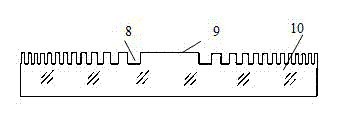

[0027] A device for detecting defects in a planar mask by bifocal zone plate interference microscopy, including a 632.8nm laser light source 1, an aperture stop 2, a positive lens 3 with a focal length of 50 mm, and a semi-transparent and semi-reflective beam splitter 4. Bifocal zone plate 5. Planar mask to be tested 6. CCD detector 7. The polarization-stabilized He-Ne laser has a working wavelength λ=632.8nm, a power of 1.5mw, and an output spot diameter of φ1mm. The laser source 1 is close to the aperture stop 2, and when the laser light is incident, a point light source is formed on the aperture stop 2. The beam splitter 4 is based on k9 glass, coated with a semi-transparent and semi-reflective dielectric film, and the dielectric film material is Sio 2 and Tio 2 . The aperture stop is located at the focal point of the positive lens 3 with a focal length of 50mm. The emitted light is parallel light. The inclination angle of the beamsplitter 4 is 45°. The diffracted light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com