Synchronous decortication method for lobsters

A lobster, ultraviolet technology, applied in food science, climate change adaptation, processing crustaceans, etc., can solve the problems of no implementation results, no implementation cases, etc., to achieve the effect of accelerating the peeling frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

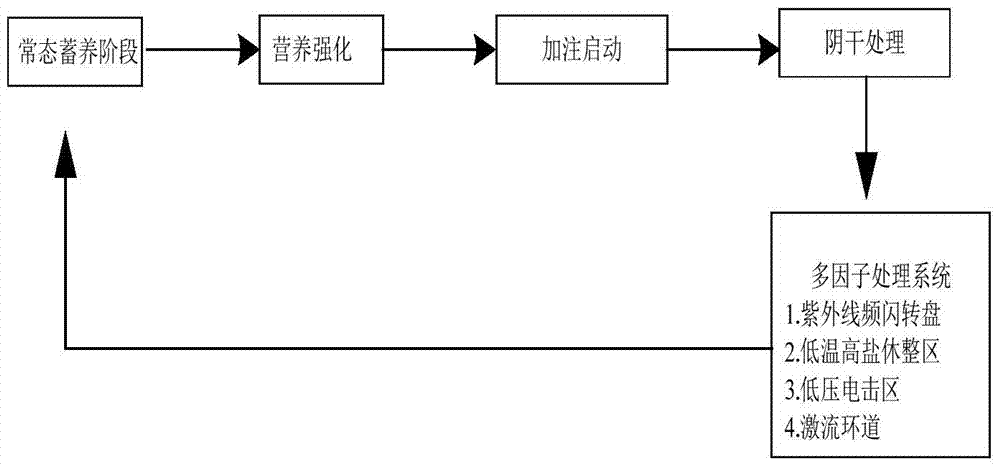

[0035] Step 1. Nutrient intensive treatment: Before the implementation of synchronous peeling technology, the cultured lobster must be cultured with nutritional enrichment to create the physiological needs of lobster peeling from the internal cause. Concentrate and feed the lobsters in sufficient quantities within 3 days with the lobster-specific compound feed developed by Longkeyuan Company, supplemented by chilled feed with 20% by weight of crustaceans or shellfish to complete the nutrient accumulation required for peeling ;

[0036] Step 2. Injection of priming elements: After the nutritional fortification treatment is completed, premix the priming elements (the main component is acidified shell powder) with the self-made special lobster compound feed at a weight ratio of 20% through the feed binder Feed for one day, once in the morning and once in the evening;

[0037] Step 3. Drying in the shade: After 24 hours of fasting the lobsters that ingested the starter elements, ...

Embodiment 2

[0047]Step 1. Nutrient intensive treatment: Before the implementation of synchronous peeling technology, the cultured lobster must be cultured with nutritional enrichment to create the physiological needs of lobster peeling from the internal cause. Concentrate and feed the lobsters in sufficient quantities in 3 days with the lobster-specific compound feed developed by Longkeyuan Company, supplemented by chilled feed with a weight ratio of 20% crustaceans, to complete the nutrient accumulation required for peeling;

[0048] Step 2. Injection of priming elements: After the nutritional fortification treatment is completed, premix the priming elements (the main component is acidified shell powder) with the self-made special lobster compound feed at a weight ratio of 20% through the feed binder Feed for one day, once in the morning and once in the evening;

[0049] Step 3. Drying in the shade: After 24 hours of fasting the lobsters that ingested the starter elements, they were conc...

Embodiment 3

[0059] Step 1. Nutrient intensive treatment: Before the implementation of synchronous peeling technology, the cultured lobster must be cultured with nutritional enrichment to create the physiological needs of lobster peeling from the internal cause. Concentrate and feed the lobsters in sufficient quantities in 3 days with the lobster-specific compound feed developed by Longkeyuan Company, supplemented with 20% crustacean or shellfish-based chilled feed, to complete the nutrient accumulation required for peeling;

[0060] Step 2. Injection of priming elements: After the nutritional fortification treatment is completed, premix the priming elements (the main component is acidified shell powder) with the self-made special lobster compound feed at a weight ratio of 20% through the feed binder Feed for one day, once in the morning and once in the evening;

[0061] Step 3. Drying in the shade: After 24 hours of fasting the lobsters that ingested the starter elements, they were concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com