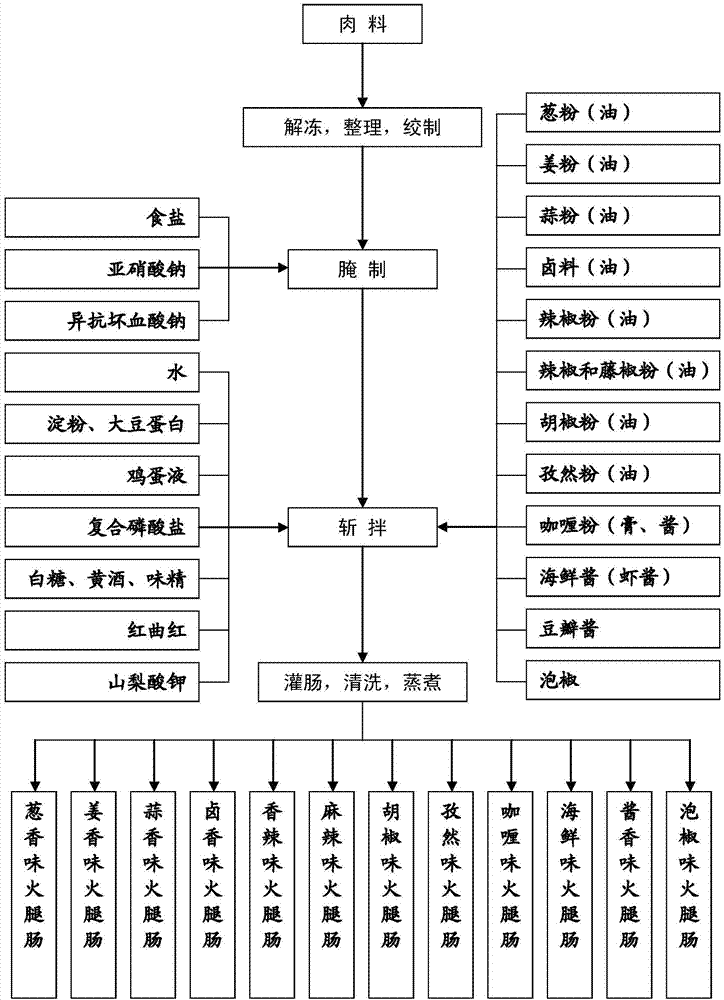

Processing method of series flavor ham sausages

A processing method and ham sausage technology are applied in the processing field of a series of flavored ham sausages, which can solve the problems of limiting the development potential and market prospects of ham sausages, and achieve the effects of promoting the growth of the market, the development of the industry, and improving the flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0024] Embodiment 1: A processing method of braised-flavored ham sausage

[0025] (1) Take 10 kg of pork with skin and bone removed (lean: fat = 7:3), wash it, and mince it (about 0.05 cm 3 ).

[0026] (2) Add table salt (200 g), sodium nitrite (0.3 g) and sodium erythorbate (2 g) to the minced meat, stir well, seal, and marinate at 4-10°C for 36 h.

[0027] (3) Add borneol (2000 g), starch (800 g), soybean protein (500 g), egg liquid (200 g), compound phosphate (10 g), white sugar (100 g) to the marinated minced meat ), rice wine (100 g), monosodium glutamate (10 g), red yeast rice (1 g), potassium sorbate (0.5 g) and marinated material (20 g) or marinated oil (100 g), first chop and mix in a low-speed vacuum for 5 min, and then high-speed vacuum emulsification for 7 min to make minced meat.

[0028] (4) Pour the chopped and mixed minced meat into PVDC plastic casings, remove the air, ligate the aluminum wire, and wash the remaining minced meat on the surface with tap wa...

Embodiment approach 2

[0030] Embodiment 2: A processing method of spicy-flavored ham sausage

[0031] (1) Take 50 kg of chicken with skin and bone removed (lean: fat = 8.5:1.5), wash and grind into minced meat (about 0.02 cm 3 ).

[0032] (2) Add table salt (1250 g), sodium nitrite (3 g) and sodium erythorbate (30 g) to the minced meat, stir well, seal, and marinate at 4-10°C for 24 h.

[0033] (3) Add borneol (15000 g), starch (7500 g), soybean protein (4000 g), egg liquid (1750 g), compound phosphate (150 g), white sugar (1500 g) to the marinated minced meat ), rice wine (1000 g), monosodium glutamate (100 g), red yeast rice (7.5 g), potassium sorbate (5 g), chili powder (500 g) or chili oil (1000 g), rattan pepper powder (250 g ) or rattan pepper oil (500 g), chop and mix in a low-speed vacuum for 3 minutes, and then emulsify in a high-speed vacuum for 5 minutes to make minced meat.

[0034] (4) Pour the chopped and mixed minced meat into PVDC plastic casings, remove the air, ligate the alu...

Embodiment approach 3

[0036] Embodiment 3: A processing method of pickled pepper-flavored ham sausage

[0037] (1) Take 20 kg of fish meat without skin, scales, bones, and fins, wash it, and grind it into minced meat (about 0.01 cm 3 ).

[0038] (2) Add table salt (600 g), sodium nitrite (2 g) and sodium erythorbate (20 g) to the minced meat, stir well, seal, and marinate at 4-10°C for 12 h.

[0039] (3) Add borneol (8000 g), starch (5000 g), soybean protein (2000 g), egg liquid (1000 g), compound phosphate (100 g), white sugar (1000 g) to the marinated minced meat ), yellow rice wine (600 g), monosodium glutamate (60 g), red yeast rice (4 g), potassium sorbate (3 g), homogenized pickled pepper (1500 g), chop and mix in a low-speed vacuum for 2 min, and then High-speed vacuum emulsification for 3 minutes to make minced meat.

[0040] (4) Pour the chopped and mixed minced meat into PVDC plastic casings, remove the air, ligate the aluminum wire, wash with tap water, and remove the remaining minc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com