Microstructured devices for producing monodisperse droplets and bubbles and methods of use thereof

A microstructure, monodisperse technology, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve the problems of complex fabrication of hydraulic focusing channels, difficult stable operation, instability, etc., to achieve structural Simple, easy-to-adjust, and mass-produced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

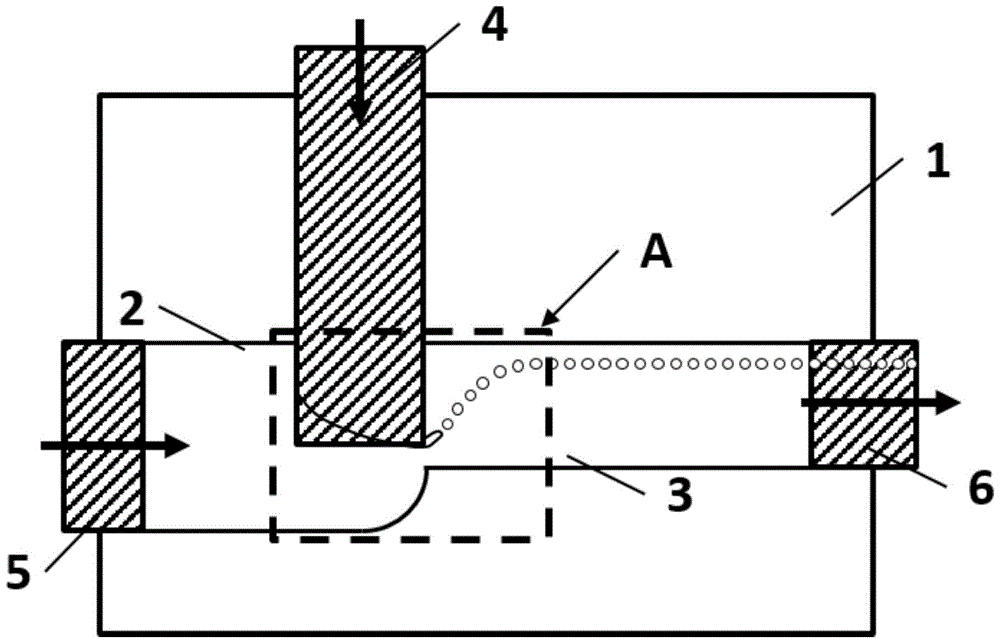

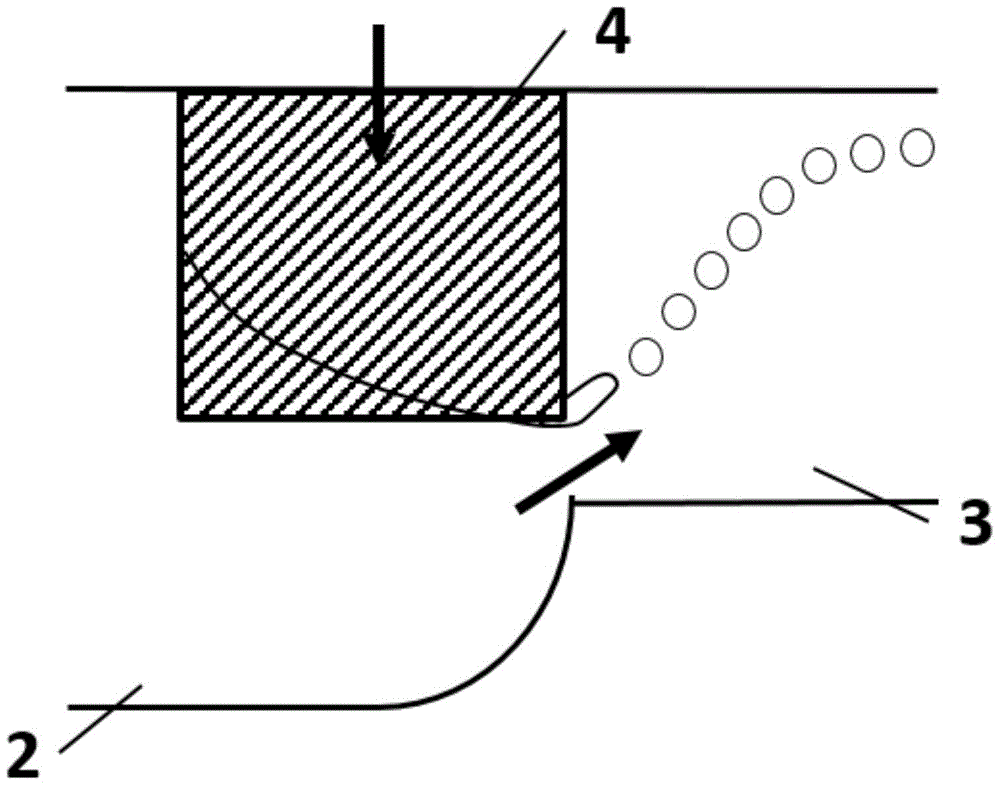

[0042] The width of the main channel with PMMA as the substrate is 1200 microns, the width of the downstream is 750 microns, and the width of the bypass channel is 750 microns. Both the main channel and the bypass channel are square grooves with a depth of 750 microns. A flat-headed quartz capillary with a diameter of 750 microns and an inner diameter of 530 microns is embedded in the bypass channel and protrudes to one side of the main channel with a protruding length of 520 microns. The continuous phase was injected using Teflon tubing and the two-phase fluid was collected. Add sodium dodecyl sulfate (SDS, the mass fraction in the continuous phase is 0.01wt%~2wt%) or cetyltrimethylammonium bromide (CTAB, the mass fraction in the continuous phase is 0.01wt%) ~2wt%) and other aqueous solutions of water-soluble surfactants are used as the continuous phase, and glycerin (mass fraction in the continuous phase is 1wt% ~ 70wt%) is added with different mass concentrations to adjust ...

Embodiment 2

[0044]The width of the main channel with stainless steel as the substrate is 1400 microns, the width of the downstream is 750 microns, the width of the bypass channel is 540 microns, the main channel and the bypass channel are square grooves, and the depth is 540 microns. A stainless steel capillary with an outer diameter of 540 microns and an inner diameter of 310 microns is embedded in the bypass channel and protrudes to one side of the main channel with a length of 520 microns. The continuous phase was injected using Teflon tubing and the two-phase fluid was collected. Add sodium dodecyl sulfate (SDS, the mass fraction in the continuous phase is 0.01wt%~2wt%) or cetyltrimethylammonium bromide (CTAB, the mass fraction in the continuous phase is 0.01wt%) ~2wt%) and other aqueous solutions of water-soluble surfactants are used as the continuous phase, and glycerin (mass fraction in the continuous phase is 1wt% ~ 70wt%) is added with different mass concentrations to adjust the ...

Embodiment 3

[0046] The width of the wide-diameter area of the main channel made of polytetrafluoroethylene is 1400 microns, the width of the narrow-diameter area is 750 microns, and the width of the bypass channel is 540 microns. Both the main channel and the bypass channel are square grooves with the same depth. A stainless steel capillary with an outer diameter of 540 microns and an inner diameter of 310 microns is embedded in the bypass channel and protrudes to the side of the main channel with a length of 520 microns. The continuous phase was injected using Teflon tubing and the two-phase fluid was collected. Add sodium dodecyl sulfate (SDS, the mass fraction in the continuous phase is 0.01wt%~2wt%) or cetyltrimethylammonium bromide (CTAB, the mass fraction in the continuous phase is 0.01wt%) ~2wt%) and other aqueous solutions of water-soluble surfactants are used as the continuous phase, and glycerin (mass fraction in the continuous phase is 1wt% ~ 70wt%) is added with different ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com