Method for synthesizing perovskite LaCoO3 composite oxide material from bagasse

A technology of composite oxide and bagasse, applied in chemical instruments and methods, cobalt oxide/cobalt hydroxide, other chemical processes, etc., can solve the problems of high cost and complicated preparation process, and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

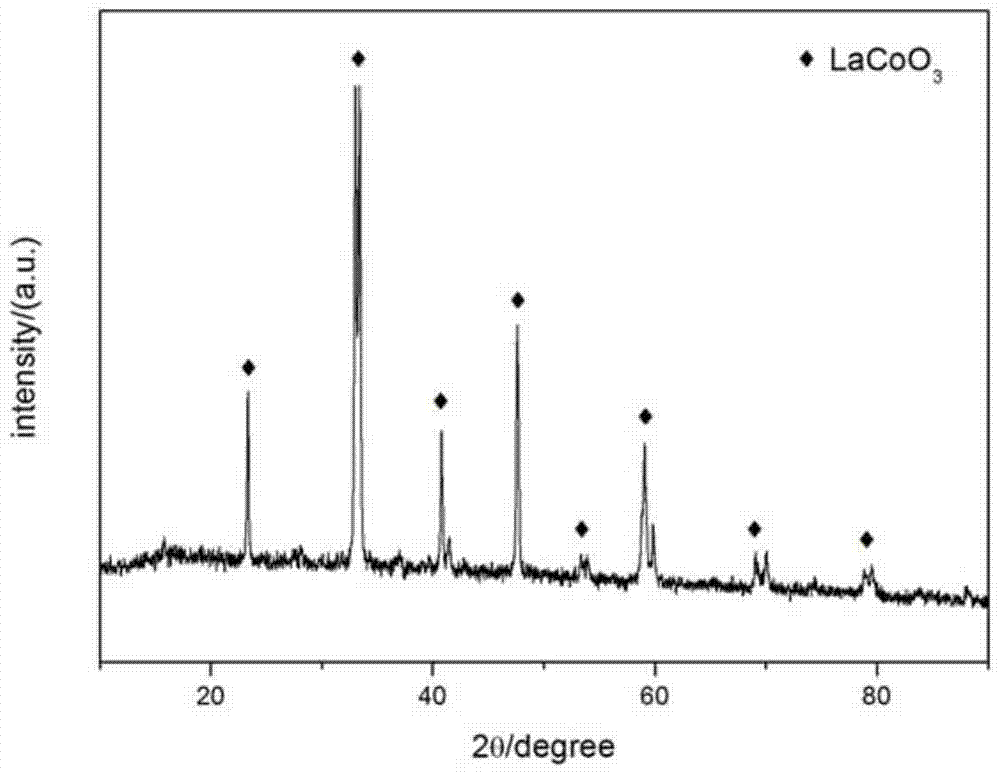

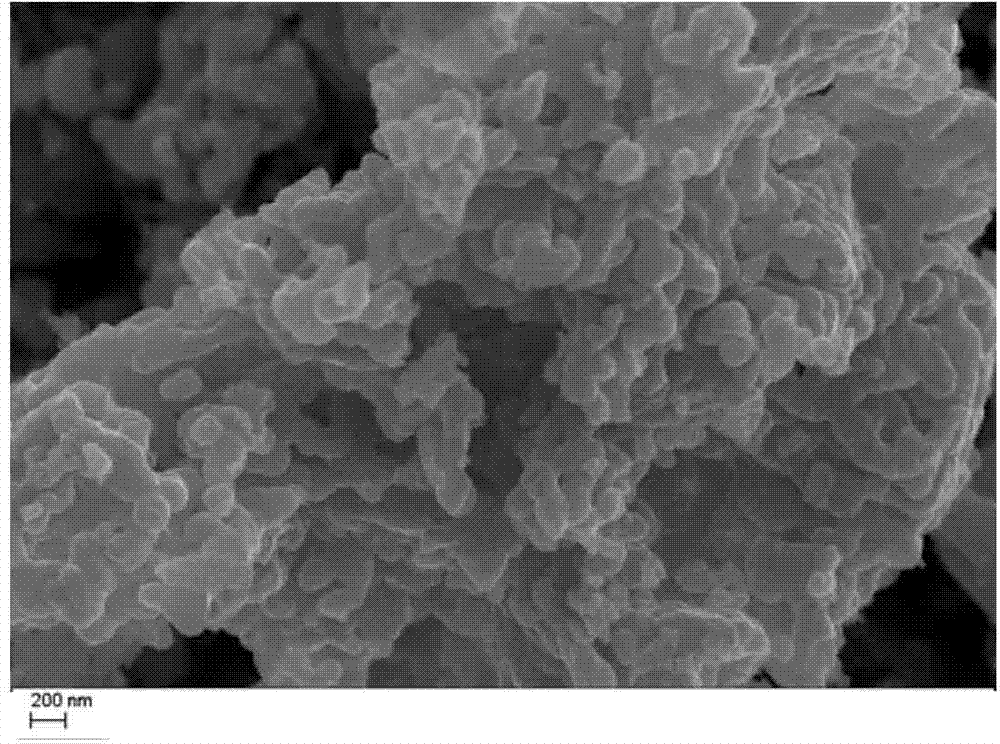

[0014] LaCoO 3 Preparation: The molar ratio of lanthanum nitrate: cobalt nitrate is 1:1. Take 0.04mol metal nitrate and dissolve in 0.1L deionized water, add relative to LaCoO 3 The mass percentage is 10% of 60 mesh bagasse. Stir evenly, dry at 80°C for 24 hours, and heat to burn in an electric furnace. The obtained precursor powder is further decomposed after roasting at 400°C for 2 hours, and then roasted at 800°C for 4 hours to obtain the nano perovskite material LaCoO 3 .

[0015] The specific surface area test was carried out on a Micromeritics TriStar 3000 automatic physical and chemical adsorption instrument. Using high-purity nitrogen as the adsorbate, the adsorption is carried out at liquid nitrogen temperature (77K). Weigh about 0.1 g of the sample, press it into tablets, and vacuumize the sample at 150°C for 5 hours before testing. The specific surface area is 6.97m 2 / g.

Embodiment 2

[0017] LaCoO 3 Preparation: The molar ratio of lanthanum nitrate: cobalt nitrate is 1:1. Take 0.04mol metal nitrate and dissolve in 0.1L deionized water, add relative to LaCoO 3 The mass percentage is 15% of 80 mesh bagasse. Stir evenly, dry at 100°C for 12 hours, and heat to burn in an electric furnace. The obtained precursor powder is further decomposed after roasting at 400°C for 2 hours, and then roasted at 700°C for 4 hours to obtain the nano-perovskite material LaCoO 3 , whose specific surface area is 6.72m 2 / g.

Embodiment 3

[0019] LaCoO 3 Preparation: The molar ratio of lanthanum nitrate: cobalt nitrate is 1:1. Take 0.04mol metal nitrate and dissolve in 0.1L deionized water, add relative to LaCoO 3 The mass percentage is 10% bagasse of 100 mesh. Stir evenly, dry at 90°C for 16 hours, and heat to burn in an electric furnace. The obtained precursor powder is further decomposed after roasting at 400°C for 2 hours, and then roasted at 600°C for 4 hours to obtain the nano-perovskite material LaCoO 3 , its specific surface area is 11.72m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com