Preparation method of filtering core material for air purifier for eliminating formaldehyde in long-acting manner

An air purifier and formaldehyde technology, applied in chemical instruments and methods, separation methods, other chemical processes, etc., can solve the problems of poor adsorption of polar molecule formaldehyde, low utilization efficiency of visible light, easy re-release, etc., to achieve environmental protection and remove formaldehyde Performance, long-lasting catalytic purification of formaldehyde, not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

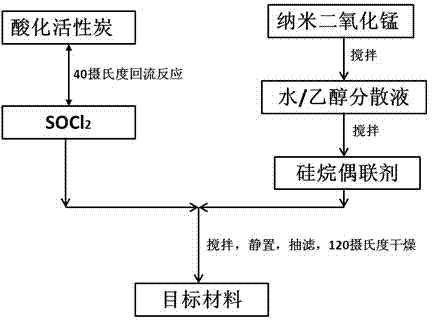

[0024] 1) Add 20 g of acidified activated carbon to 10 ml of SOCl 2 In the liquid and reflux reaction at 40 degrees Celsius for 2 hours, acid chloride activated carbon will be obtained;

[0025] 2) Put 1 gram of nano-manganese dioxide into 100 ml of ethanol / water (the volume ratio of ethanol and water is 4:1) dispersant, and stir for 30 minutes to obtain a manganese dioxide solution;

[0026] 3) Add 0.02 g of aminosilane coupling agent to the manganese dioxide solution to obtain nano manganese dioxide solution modified by silane coupling agent;

[0027] 4) Add the above acid chloride activated carbon into the nano-manganese dioxide solution modified by silane coupling agent, stir for 1 hour, and vacuum filter;

[0028] 5) Vacuum-dry the product of step 4) at 120 degrees Celsius for 12 hours to obtain a long-term formaldehyde-removing air purifier filter element material.

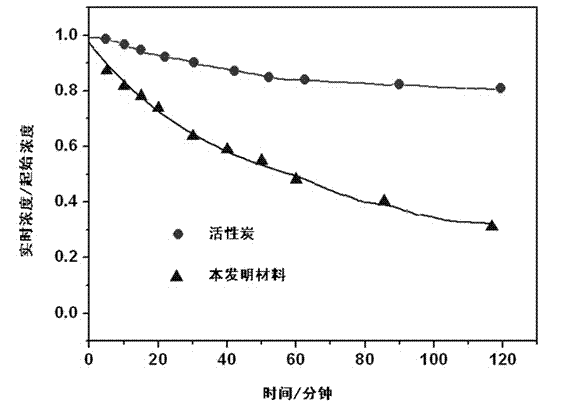

[0029] The filter element material obtained above and the activated carbon of the same quality are put ...

Embodiment 2

[0031] 1) Add 20 g of acidified activated carbon to 20 ml of SOCl 2 Liquid and reflux reaction at 50 degrees centigrade for 2 hours to obtain activated carbon acid chloride;

[0032] 2) Put 1 g of manganese dioxide into 200 ml of ethanol / water (the volume ratio of ethanol and water is 4:1) dispersant, and stir for 30 minutes to obtain a manganese dioxide solution;

[0033] 3) Add 0.02 g of aminosilane coupling agent to the manganese dioxide solution to obtain nano manganese dioxide solution modified by silane coupling agent;

[0034] 4) Add the above acid chloride activated carbon into the nano-manganese dioxide solution modified by silane coupling agent, stir for 1 hour, and vacuum filter;

[0035] 5) Vacuum-dry the product of step 4) at 130 degrees Celsius for 12 hours to obtain a long-term formaldehyde-removing air purifier filter element material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com