Novel lepidolite floating selecting method, collecting agent and application thereof

A technology of lepidolite and collector, applied in the field of collectors, can solve the problems of low recovery efficiency of lepidolite concentrate, high cost of chemicals, environmental pollution, etc., and achieves improved comprehensive utilization value, low consumption of chemicals, and environmental friendliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in further detail now in conjunction with embodiment.

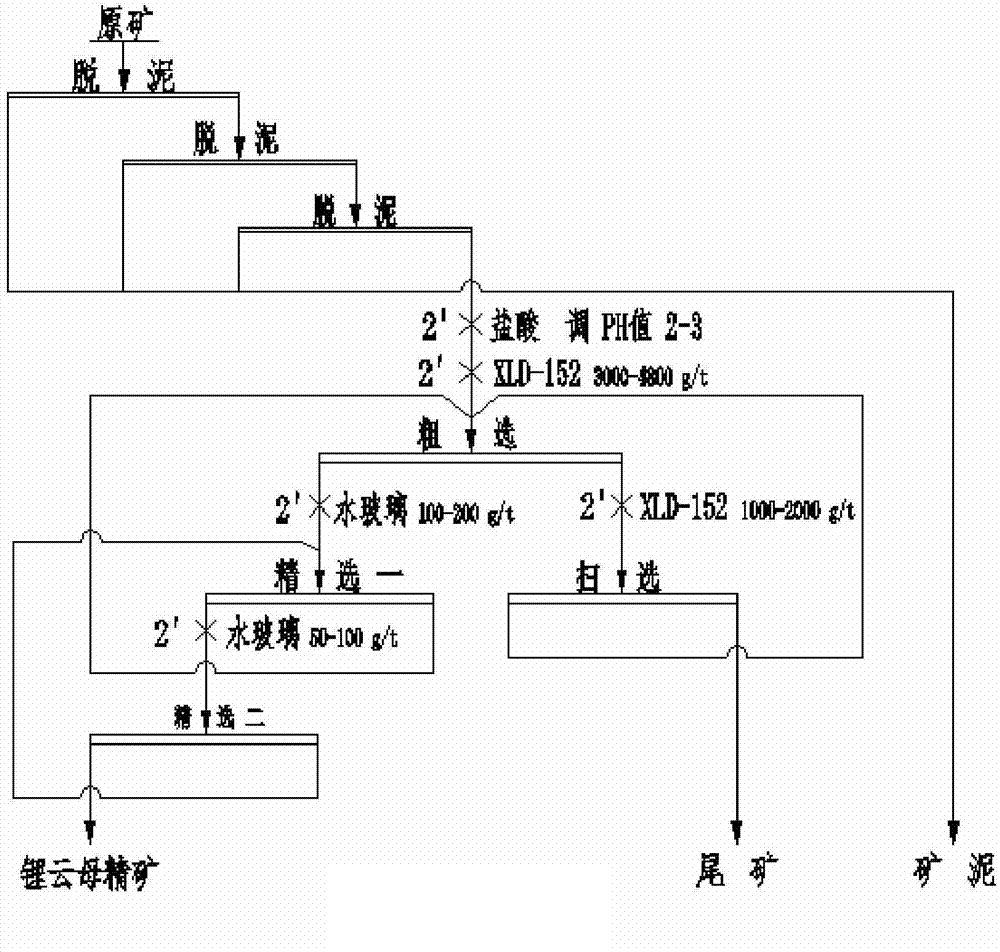

[0032] A novel lepidolite flotation method, such as figure 1 As shown, it mainly includes three desliming, one roughing, two refining and one sweeping.

[0033] Specific steps are as follows:

[0034] 1 desliming three times

[0035] 1.1 The first desliming of raw ore with cyclone

[0036] 1.2 The first desliming product uses a hydraulic classifier for the second desliming

[0037] 1.3 Use the hydraulic classifier again for the third desliming

[0038] After the above three times of desliming, more than 90% of the slime less than 0.010mm is removed, and it becomes the ore feed for roughing

[0039] 2 rough selection

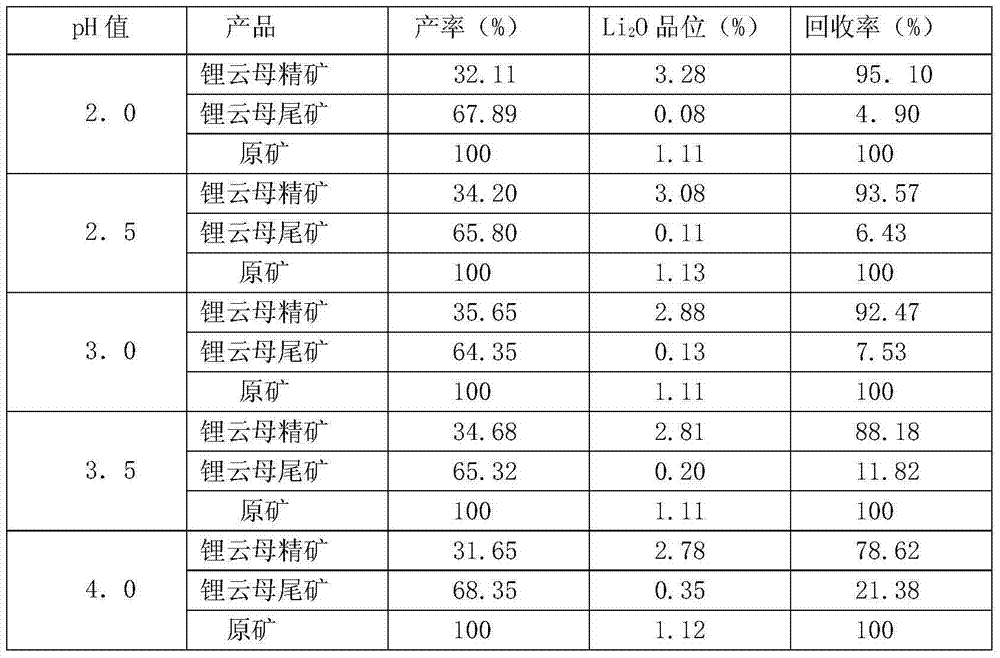

[0040] 2.1 Use a mechanical flotation machine to float the deslimed product, add hydrochloric acid 3000-5000g / t, stir for 2-6 minutes, and adjust the pH value of the pulp to 2-3.

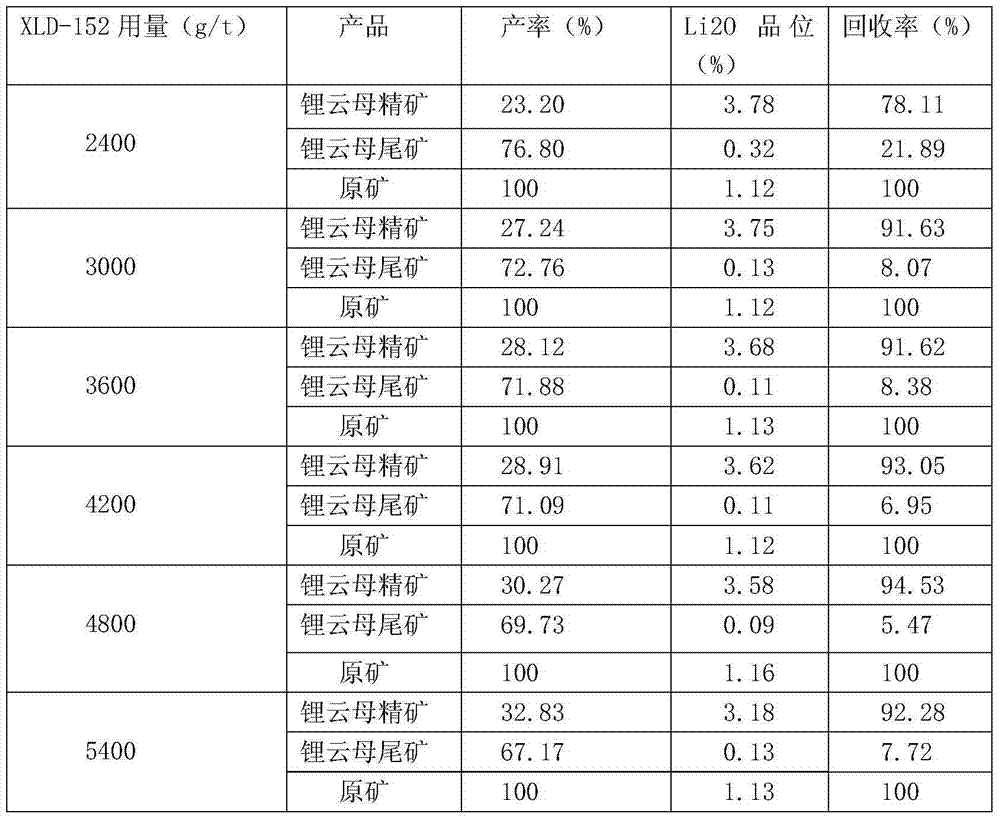

[0041] 2.2 Then add 3000-4800g / t collector XLD-152 and stir for 1-2 minutes. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com