Nano-sphere with elements of silicon, cobalt and like as well as synergetic ammonium polyphosphate flame resistant polypropylene material thereof

A technology of flame-retardant polypropylene and nano-microspheres, which is applied in the field of flame-retardant polypropylene materials, can solve the problems of endangering life and property safety, polypropylene is flammable, and has a fast burning speed, and achieves less secondary pollution and flame retardant. Efficiency enhancement and dosage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

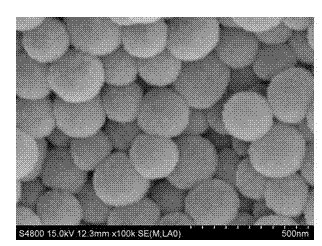

Image

Examples

Embodiment 1

[0029] Embodiment 1: take by weighing 600 grams of polypropylene pellets, 260 grams of ammonium polyphosphate, 30 grams of pentaerythritol, 110 grams of nano-microspheres containing elements such as silicon and cobalt, and mix the above pellets in a high-speed mixer. Under the conditions of conventional feeding speed, temperature and screw speed, feed into a twin-screw extruder, extrude, cool, and granulate to obtain the nano-microspheres containing silicon, cobalt and other elements of the present invention synergistically with ammonium polyphosphate flame-retardant polypropylene. The limiting oxygen index is 35.5%, the vertical combustion is V-0, the carbon residue rate at 600°C is 32.7%, and there is no droplet phenomenon.

Embodiment 2

[0030] Embodiment 2: take by weighing 700 grams of polypropylene pellets, 220 grams of ammonium polyphosphate, 30 grams of pentaerythritol, 50 grams of nano-microspheres containing elements such as silicon and cobalt, and mix the above pellets in a high-speed mixer. Under the conditions of conventional feeding speed, temperature and screw speed, feed into a twin-screw extruder, extrude, cool, and granulate to obtain the nano-microspheres containing silicon, cobalt and other elements of the present invention synergistically with ammonium polyphosphate flame-retardant polypropylene. The limiting oxygen index is 29.3%, the vertical combustion is V-0, the carbon residue rate at 600°C is 10.8%, and there is no droplet phenomenon.

Embodiment 3

[0031]Embodiment 3: take by weighing 700 grams of polypropylene pellets, 190 grams of ammonium polyphosphate, 30 grams of pentaerythritol, 80 grams of nano-microspheres containing elements such as silicon and cobalt, and mix the above pellets in a high-speed mixer. Under the conditions of conventional feeding speed, temperature and screw speed, feed into a twin-screw extruder, extrude, cool, and granulate to obtain the nano-microspheres containing silicon, cobalt and other elements of the present invention synergistically with ammonium polyphosphate flame-retardant polypropylene. The limiting oxygen index is 26.3%, the vertical combustion is V-2, the carbon residue rate at 600°C is 22.1%, and there is no obvious droplet phenomenon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com