Inorganic passivation material, method for forming the same, and inorganic passivation protective film produced therefrom

A protective film and inorganic technology, applied in the direction of anti-corrosion coatings, coatings, metal material coating technology, etc., can solve the problems of insufficient weather resistance and heat resistance, and achieve good heat resistance, good adhesion and compactness, The effect of high corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

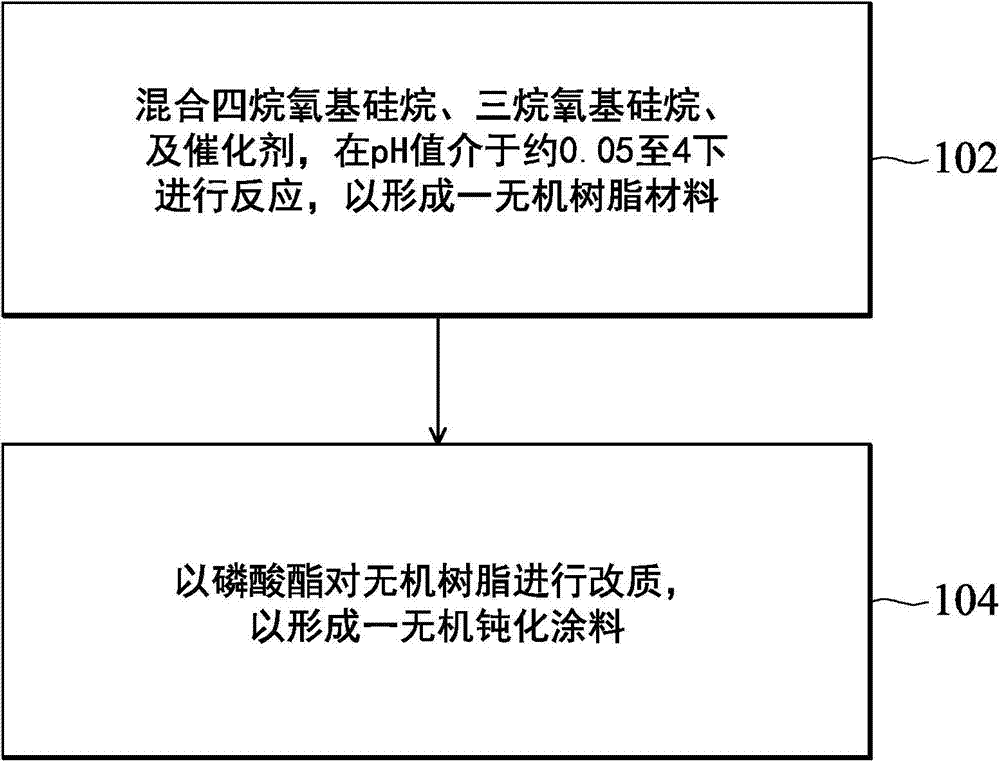

Method used

Image

Examples

Embodiment 1

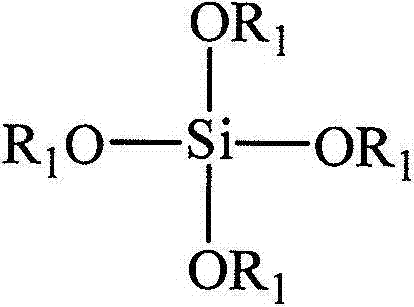

[0047] Mix tetraethoxysilane (TEOS), methyltriethylsilane (MTES), and epoxypropyltriethoxysilane (3-glycidoxypropyltrimethoxysilane; GPTMS) uniformly according to the ratio in Table 3, and stir at room temperature for 10 minutes Finally, water and 0.1N hydrochloric acid were added according to the ratio in Table 3, and then the sol-gel (sol-gel) reaction was carried out at room temperature for 16 hours, then the temperature was raised to 60°C, and the reaction was continued for 8 hours. An inorganic resin material with a partial network structure. Then add isopropyl alcohol (IPA), butyl phosphate titanoxane (Titanium, Bu phosphate Et alc.iso-Pr alc.Complexes; TBEP) (CAS NO.109037 -78-7) and uniformly mixed, stirred and reacted at room temperature for 16 hours, an inorganic passivation coating was formed.

Embodiment 2

[0049] The manufacturing process is the same as in Example 1, except that butyl titanoxane phosphate (TBEP) is replaced by diethylphosphatoethyl triethoxysilane (PHS).

[0050] The inorganic passivation coating formed in Examples 1-2 was further heated up to 800-C with a thermal gravimetric analysis (TGA) to analyze the inorganic content (Char yield) of the inorganic passivation coating. In addition, film formation evaluation was performed. After drying for 5 minutes, drop a drop of water on the test piece, wipe it off after 1 minute, and observe whether there are traces. If there is no, it is ο, indicating that the coating can form a film and dry completely.

[0051] The inorganic passivation coatings of Examples 1-2 were coated with a rod (bar-coating) on a commercially available blank hot-dip galvanized steel sheet (Yehui Iron and Steel; Model SGC-CZSWX Z-12), and dried at 200°C for 5 Minutes to form an inorganic passivation protective film. The salt spray test is carrie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com