Self-adhesion reactive, water-swellable and waterproof sealing material and production method thereof

A water-swelling, waterproof sealing technology, applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of solid waste desulfurization gypsum cannot be effectively used, and waterproof sealing products are not available. , to prevent the overall loss of function of the waterproof sealing material, prevent infiltration, and broaden the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

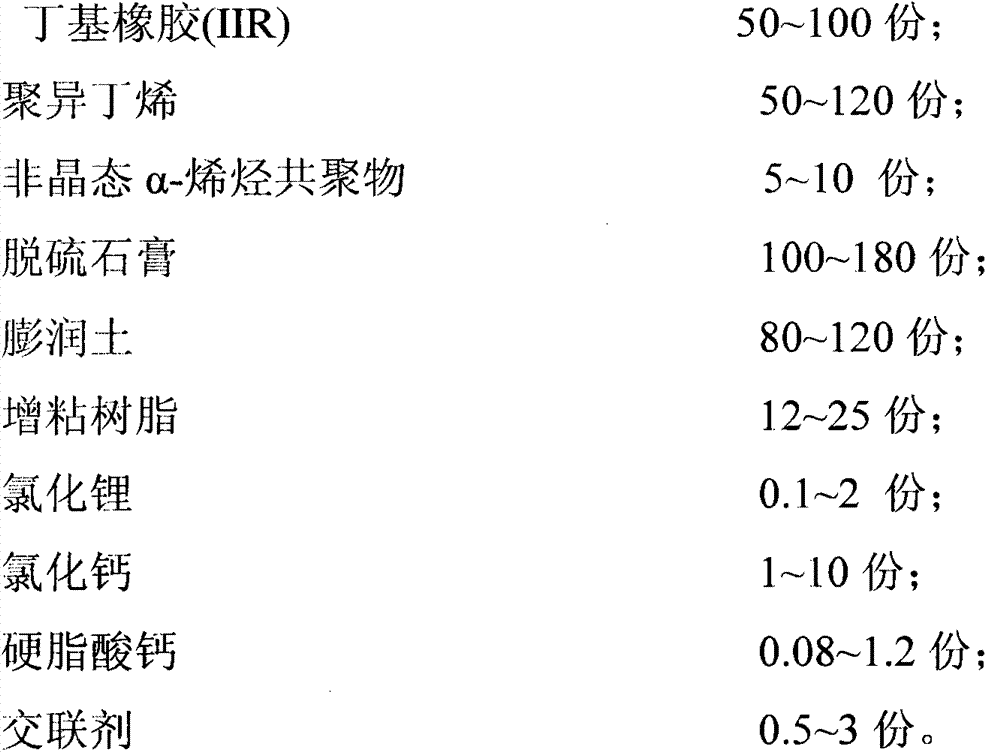

[0023] This self-adhesive reactive water-swellable waterproof sealing material is based on butyl rubber, and other raw materials include polyisobutylene, amorphous α-olefin copolymer, desulfurized gypsum, bentonite, tackifying resin, lithium chloride, calcium chloride , calcium stearate, crosslinking agent, by weight, the proportioning of above-mentioned each component is as follows:

[0024]

[0025] The production method of this self-adhesive reactive water-swellable waterproof sealing material is as follows:

[0026] a. Rubber mixing

[0027] (1), each component of butyl rubber, amorphous α-olefin copolymer, desulfurized gypsum and calcium stearate in the raw material is put into the internal mixer by weight percentage for mixing, and the mixing temperature is controlled at 105 ~120℃, mixing time 3~8 minutes;

[0028] (2) After the mixed rubber is discharged, it is sent to the open mill for heat dissipation, the roller temperature is <55°C, and the roller distance is 6...

Embodiment 2

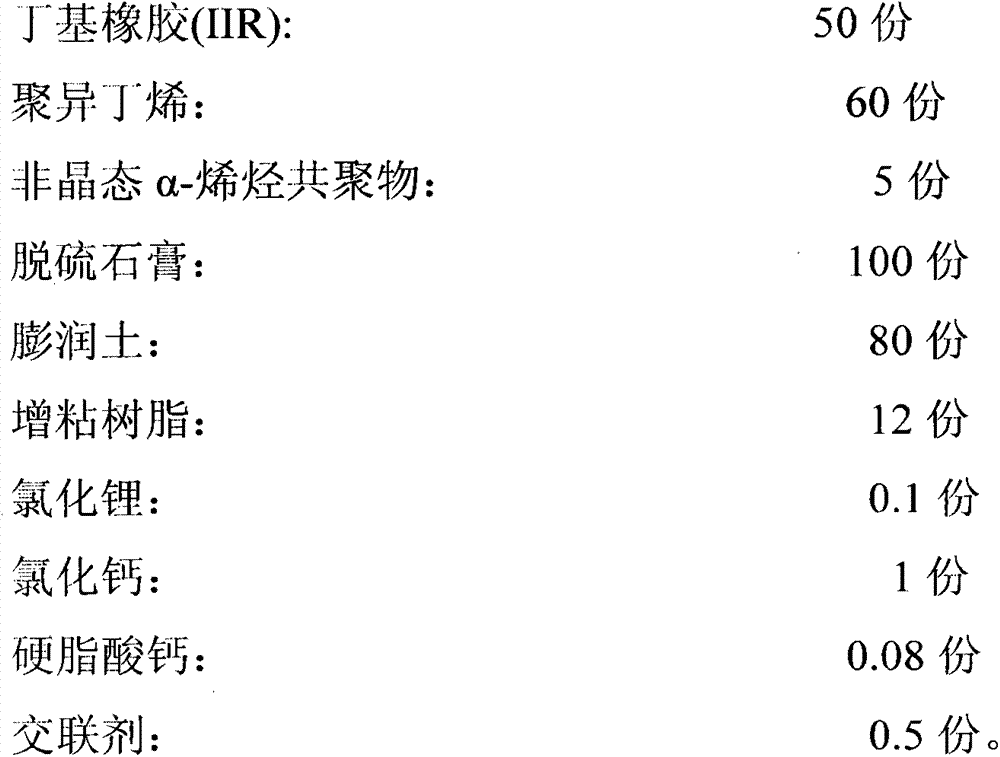

[0035] This self-adhesive reactive water-swellable waterproof sealing material is based on butyl rubber, and other raw materials include polyisobutylene, amorphous α-olefin copolymer, desulfurized gypsum, bentonite, tackifying resin, lithium chloride, calcium chloride , calcium stearate, crosslinking agent, by weight, the proportioning of above-mentioned each component is as follows:

[0036]

[0037]

[0038] The production method of this self-adhesive reactive water-swellable waterproof sealing material is as follows:

[0039] a. Rubber mixing

[0040] (1), each component of butyl rubber, amorphous α-olefin copolymer, desulfurized gypsum and calcium stearate in the raw material is put into the internal mixer by weight percentage for mixing, and the mixing temperature is controlled at 105 ~120℃, mixing time 3~8 minutes;

[0041] (2) After the mixed rubber is discharged, it is sent to the open mill for heat dissipation, the roller temperature is <55°C, and the roller d...

Embodiment 3

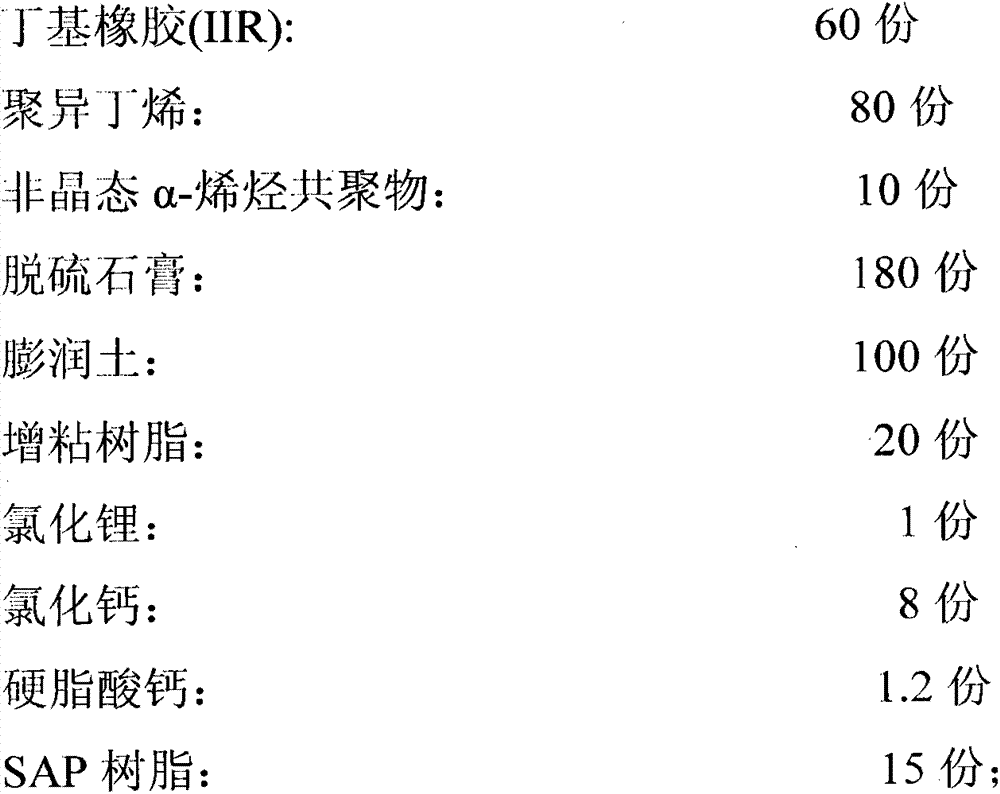

[0049] This self-adhesive reactive water-swellable waterproof sealing material is based on butyl rubber, and other raw materials include polyisobutylene, amorphous α-olefin copolymer, desulfurized gypsum, bentonite, tackifying resin, lithium chloride, calcium chloride , calcium stearate, crosslinking agent, by weight, the proportioning of above-mentioned each component is as follows:

[0050]

[0051]

[0052] The production method of this self-adhesive reactive water-swellable waterproof sealing material is as follows:

[0053] a. Rubber mixing

[0054] (1), each component of butyl rubber, amorphous α-olefin copolymer, desulfurized gypsum and calcium stearate in the raw material is put into the internal mixer by weight percentage for mixing, and the mixing temperature is controlled at 105 ~120℃, mixing time 3~8 minutes;

[0055] (2) After the mixed rubber is discharged, it is sent to the open mill for heat dissipation, the roller temperature is <55°C, and the roller d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com