A kind of high performance oil and gas well cement dispersant and preparation method thereof

A cement dispersant and dispersant technology, which is applied in the field of oil and gas well cementing, can solve problems such as unsatisfactory requirements, poor dispersion effect, and adverse effects of cement slurry thickening curve, etc., to reduce costs, improve dispersion efficiency, and uniform products No precipitation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

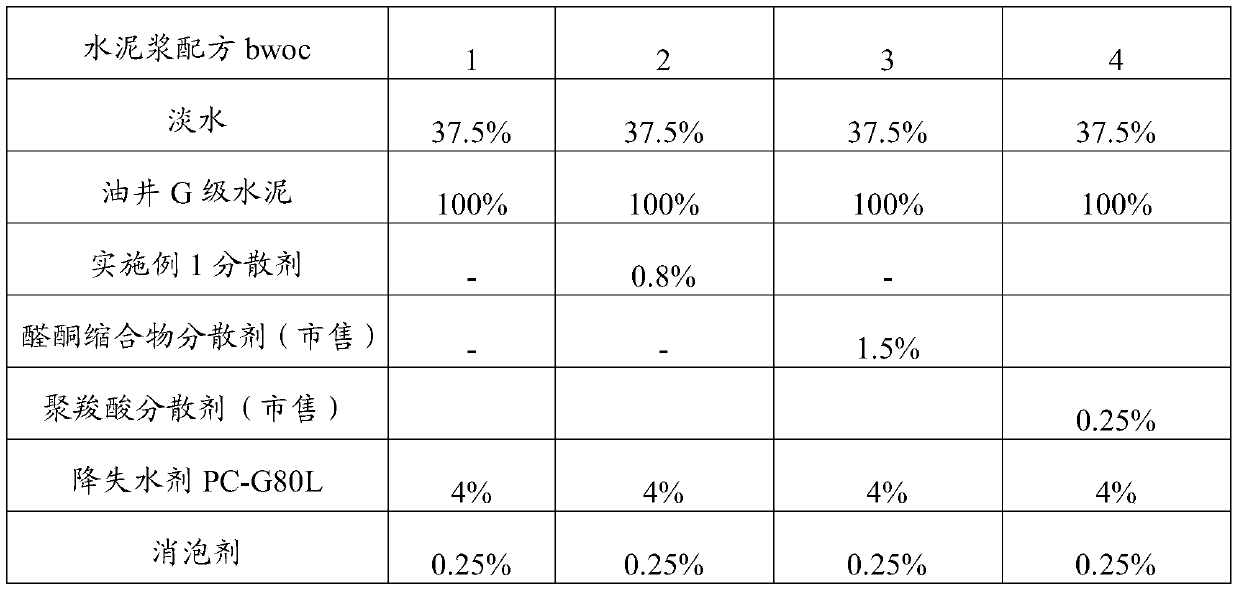

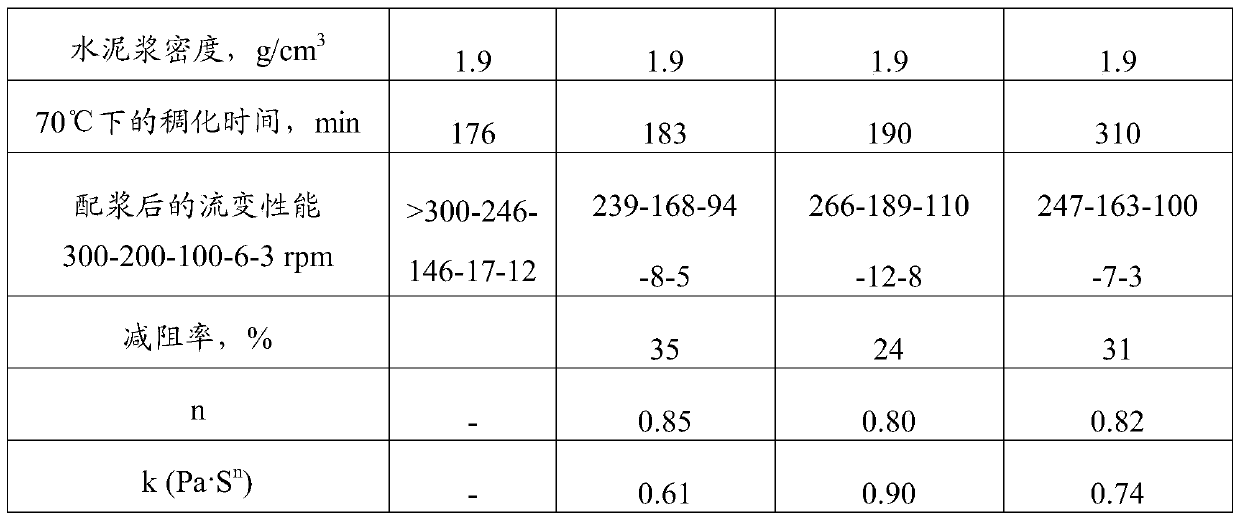

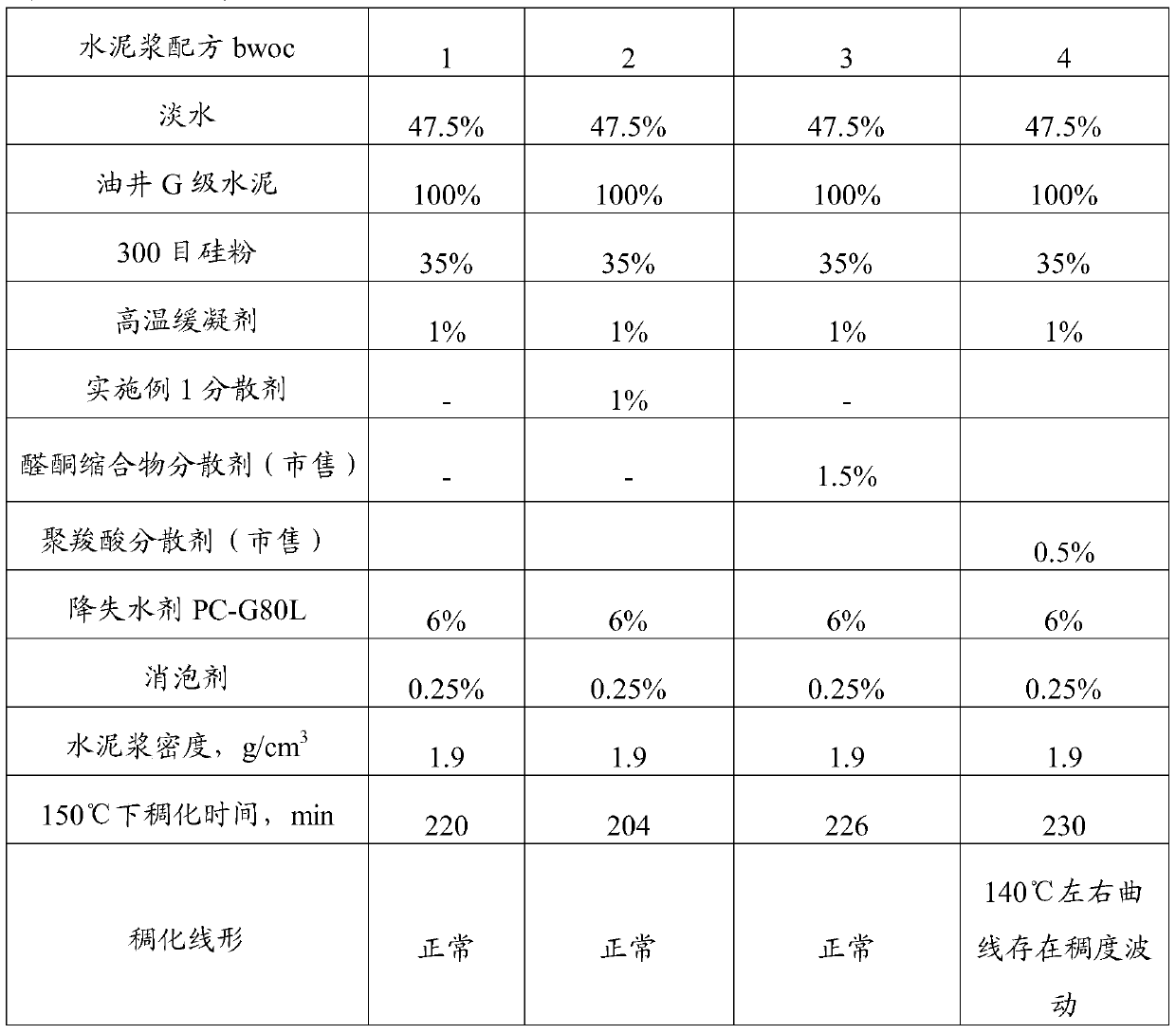

Examples

Embodiment 1

[0032] The high-performance oil and gas well cement dispersant of the present embodiment is prepared through the following steps:

[0033] a. Mix 222g polyethylene glycol monomethyl ether methacrylate, 44.5g α-methacrylic acid, 33.5g 2-acrylamido-2-methylpropanesulfonic acid and 650g deionized water to obtain 950g aqueous solution A ;

[0034] b. Dissolve 4.5g of sodium persulfate in 45.5g of deionized water to obtain 50g of aqueous solution B;

[0035] c. When the temperature of the reactor is 80°C, add the aqueous solution B dropwise to the aqueous solution A to carry out the polymerization reaction, control the reaction temperature at 80°C, and control the reaction time at 4h;

[0036] d. The reactant is cooled to room temperature, adjusted to pH 7 with NaOH, and discharged to obtain 1000 g of polycarboxylic acid dispersant;

[0037] e. Mix 1000g of this polycarboxylic acid dispersant with 1000g of sulfonated acetone-formaldehyde condensate dispersant evenly for compoundi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com