Brewing method capable of increasing content of Monacolin K in monascus rice wine

A technology of red yeast rice wine and red yeast rice wine, which is applied in the field of wine making, can solve the problems of loss of functional components of red yeast rice for lipid-lowering, etc., and achieve the effect of increasing product added value, reducing losses, and enhancing the effect of lipid-lowering health care

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: the preparation of functional red yeast rice (powder)

[0037] After 40g of indica rice was soaked, steamed and cooled, it was inoculated with Monascus spore suspension, the inoculation amount was 1.0×10 5 per g indica rice, adjust the initial moisture content to 40% with pH 5.2 sterile lactic acid aqueous solution, ferment and cultivate at 30°C, shake the flask three times a day after 2 days, and finish the fermentation after a total of 7 days, then dry at 45°C to reduce the moisture content to 14 % or less to obtain seed koji; 5kg indica rice was treated the same as above, then inserted 10g seed koji, adjusted the initial moisture content to 40% with pH 5.2 sterile lactic acid aqueous solution, and fermented and cultivated at 30°C. After 2 days of fermentation, shake the bottle three times a day, and ferment for 4 days Afterwards, the temperature was lowered to 23° C. to continue culturing for 8 days, and dried at 45° C. to reduce the water content to be...

Embodiment 2

[0040] Embodiment 2: the preparation of functional red yeast rice (powder)

[0041] Prepare functional red yeast rice as follows:

[0042] (1) The indica rice is soaked, steamed and cooled;

[0043] (2) inoculate the Monascus spore suspension in the indica rice processed in the previous step, and adjust the initial water content to 35-40%, ferment at 30°C for 6-7 days, and dry until the water content drops below 14% to obtain kind of song;

[0044] (3) Inoculate the seed koji of 0.2-0.3% by mass fraction into the indica rice treated in the same way as in step 1, and adjust the initial moisture content to 35-40%, ferment at 30°C for 3-4 days and then cool down to 23°C to continue fermentation 7-8, and then dry until the moisture content drops below 14% to obtain functional red yeast rice.

[0045] In the obtained functional red yeast rice, the Monacolin K content and glucoamylase activity were 2.077-2.142mg / g and 624-653U / g, respectively.

Embodiment 3

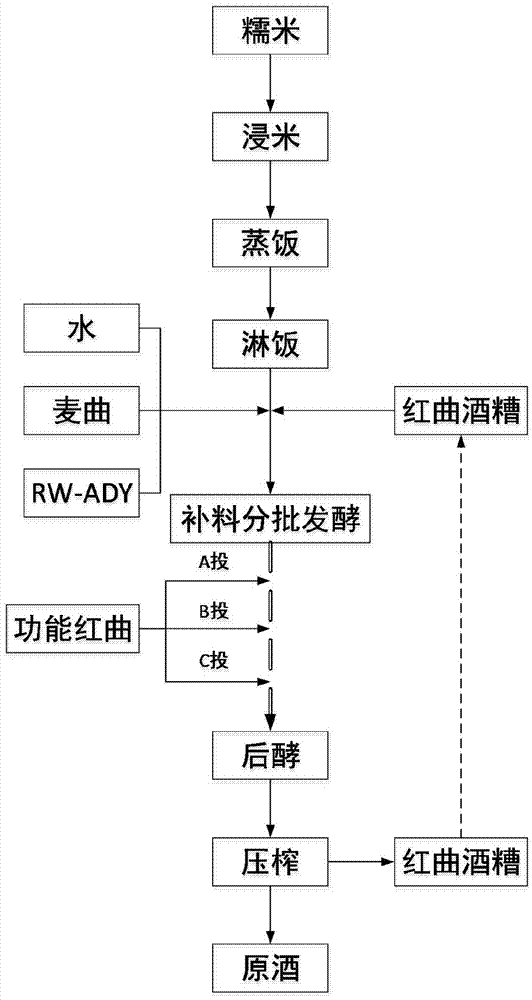

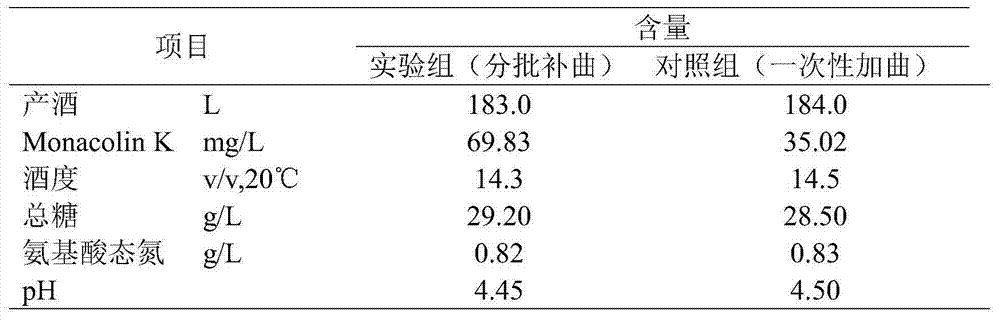

[0046] Embodiment 3: the brewing that contains Monacolin K red yeast rice wine

[0047] (1) Rice soaking: 100kg glutinous rice soaking tank, add water, stir and remove floating impurities, soak for 8 hours in summer.

[0048] (2) Steamed rice: After the soaked glutinous rice is drained, it is sent to a vertical rice steamer by a conveyor belt to steam the rice. The rice must be consistent inside and outside without white heart.

[0049] (3) Drain the rice: the steamed glutinous rice is sprayed with water on the conveyor belt to cool it down to 34°C to facilitate inoculation and fermentation. At this time, the rice absorbs 30% of water and weighs 130kg.

[0050] (4) Blanking: drop 149kg of water, 130kg of glutinous rice, 5kg of wheat koji, 3kg of red koji distiller's grains and 1kg of activated RW-ADY into a sterilized 500L fermenter and mix evenly according to the production formula. The product temperature after feeding is required to be 26°C. After 10 hours of saccharific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com