Stepped density melt-blown nonwoven fabric, manufacturing method thereof and sound absorption materials made of same

A melt-blown non-woven fabric and density technology, applied in the field of non-woven materials, can solve the problems of unsatisfactory sound absorption effect, difficult audio sound absorption effect, etc., and achieve the effects of good sound absorption and sound insulation effect, simple preparation method, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation of embodiment 1PP fiber gradient density melt-blown nonwoven fabric

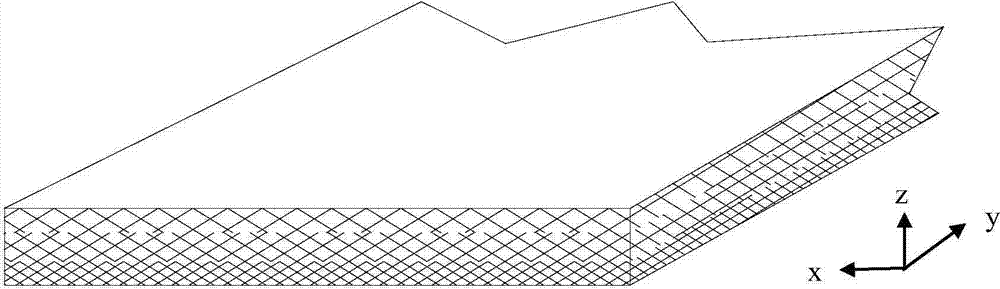

[0035] A kind of step density melt-blown nonwoven fabric, its density decreases stepwise along the thickness direction, and its density along the length and width directions is the same.

[0036] The stepwise decrease in density is 3kg / m every 1.5mm 3 , the maximum density is 40kg / m 3 , the minimum density is 16kg / m 3 .

[0037] The raw material is prepared as PP fiber slices, and the fineness of PP fiber is about 2 μm.

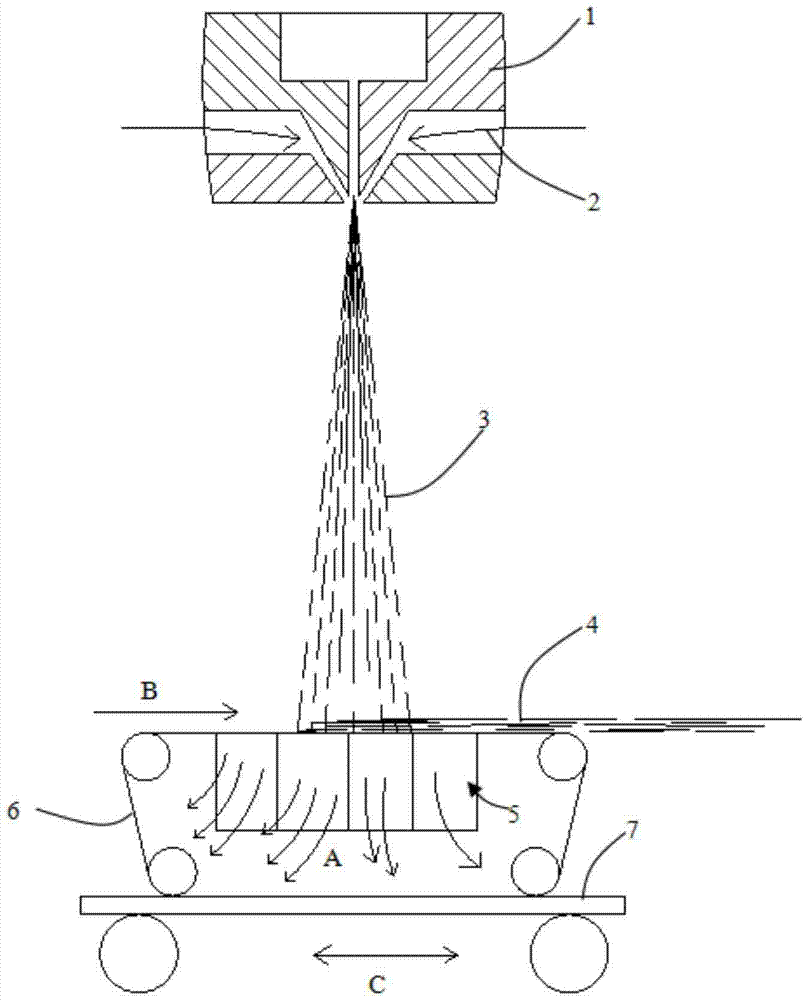

[0038] combine figure 2 , the preparation method comprises the following steps:

[0039] (1) Feed polymer fiber slices into the hopper, flow into the screw extruder, be heated and melted, filtered and metered, and extruded from the die spinneret hole 1 to form a thin stream 3 of polymer melt;

[0040](2) The heated air 2 is blown out at a high speed from the air ducts on both sides of the die spinneret hole 1, and stretches the thin stream 3 of the polymer melt...

Embodiment 2

[0044] The preparation of embodiment 2PET fiber gradient density melt-blown nonwoven fabric

[0045] A kind of step density melt-blown nonwoven fabric, its density decreases stepwise along the thickness direction, and its density along the length and width directions is the same.

[0046] The stepwise decrease in density is 3.5kg / m every 1.5mm 3 , the maximum density is 45kg / m 3 , the minimum density is 17kg / m 3 .

[0047] The raw material is prepared as dried PET fiber slices, and the fineness of the PET fiber is about 3 μm.

[0048] Preparation method: with embodiment 1.

[0049] The formed PET fiber gradient density melt-blown nonwoven fabric has the same density in the length and width directions, and the density distribution in the thickness direction from bottom to top is as follows:

[0050] Thickness (mm)

Embodiment 3

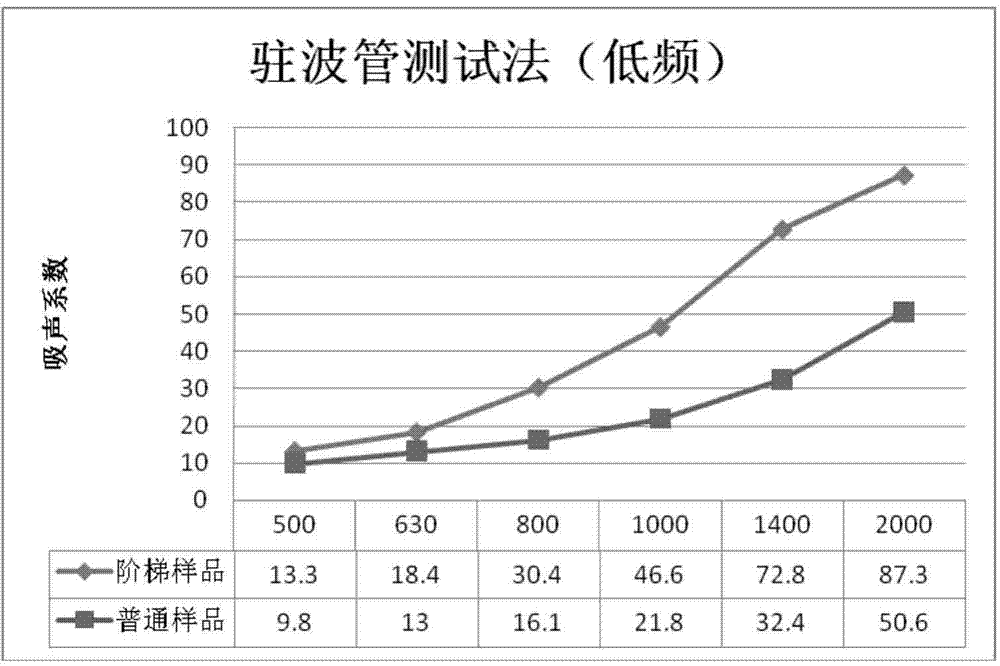

[0051] Embodiment 3 Preparation of sound-absorbing material

[0052] The upper and lower layers of the PP fiber gradient density melt-blown nonwoven fabric made in Example 1 are respectively composited with the first spunbond fabric (PP spunbond fabric) and the second spunbond fabric (PP spunbond fabric), and the three-layer cloth passes through The mesh curtain is sent to the middle of two spaced heat rollers for pre-pressing once to effectively bond the spunbond fabric and the melt-blown layer together to make a sound-absorbing material. Wherein, the grammage of the first spunbonded cloth is 15g / m 2 , the grammage of the second spunbond cloth is 15g / m 2 .

[0053] The weight of the sound-absorbing material is 400g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com