Online power station main steam flow calculation method based on flow correction

A technology of main steam flow and calculation method, which is applied in the field of machine learning modeling and can solve problems such as poor adaptability, poor robustness, and reducing the accuracy of steam flow calculation results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

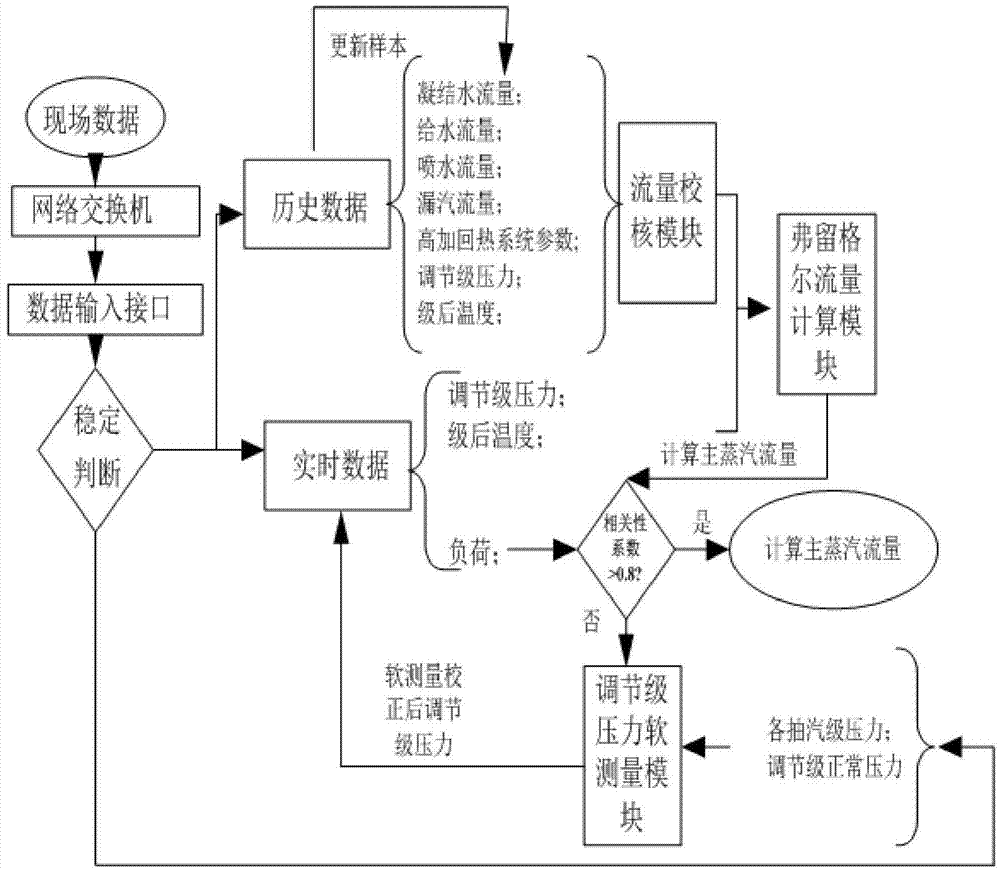

[0052] The present invention will be further described below in conjunction with the accompanying drawings.

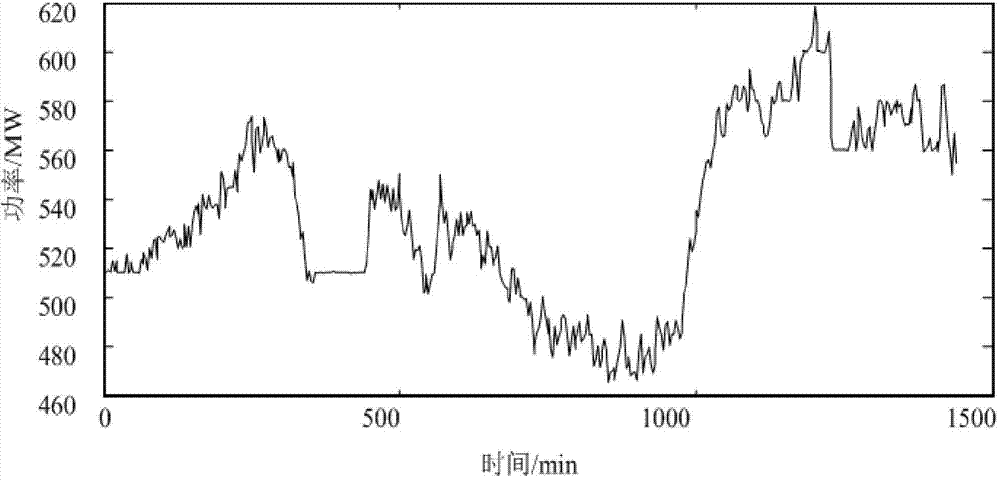

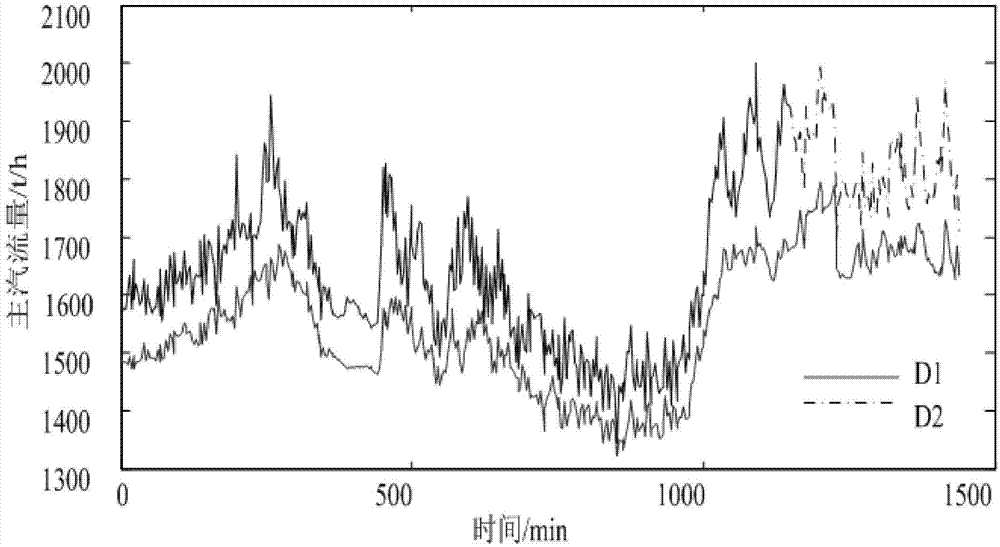

[0053] Taking a 600MW supercritical intermediate reheat condensing unit in a power station as an example, the data in the SIS system was collected from 10:00 on April 1, 2014 to 10:00 on April 10, 2014, with an interval of 1 minute. The framework of the present invention mainly includes core modules such as input data preprocessing, flow checking module, main steam flow calculation module, and pressure soft measurement at the regulating level. The detailed process is as follows: figure 1 Shown:

[0054] 1) Field data is output to the data interface via the network switch;

[0055] 2) Collect the condensate flow (D ns ), feed water flow (D gs ), steam leakage of medium pressure door lever (D kf ), high-pressure door lever steam leakage (D af ), reheat spray flow (D zr ), superheated spray flow (D gr ), unit load (P load ), post-stage pressure (P 10 ), post-stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com