Sludge deep dehydration treatment method

A technology of deep dehydration and treatment method, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. Low utilization efficiency and other problems, to achieve the effect of reducing toxic and harmful substances, reducing stacking, and reducing absolute quantity

Inactive Publication Date: 2015-07-08

KUNSHAN MAYMUSE ENVIRONMENTAL TECH

View PDF11 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantages are that the equipment structure is more complicated, the current action time is limited, the current utilization efficiency is low, and the sludge surface structure is not effectively changed, the extracellular polymer is stripped, and the cell wall is damaged.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0037] 1) First, import 1L of sludge with a solid content of 2% into the oxidation device;

[0038] 2) Next, add 0.1% of the sludge amount of oxidant hypochlorous acid into the oxidation device.

[0039] 3) After 3 hours, it was observed that it changed from black to gray, and the oxidation treatment was stopped, and the sludge was discharged for centrifugation treatment (1000rpm, 5 minutes), and the treated sludge 1 was obtained.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture content | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

Login to View More

Abstract

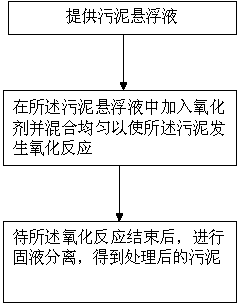

The invention discloses a sludge deep dehydration treatment method. The treatment method comprises the following steps: a) providing sludge suspension; b) adding an oxidant into the sludge suspension, and evenly mixing so that the sludge has oxidization reaction; and c) after the oxidization reaction is over, carrying out solid-liquid separation to obtain the sludge to be treated. According to the sludge deep dehydration treatment method, before the solid and liquid separation is conducted, the oxidization reaction is conducted to the sludge through the oxidant, the surface structure is effectively changed, extracellular polymers are peeled, cell walls are broken, so that the dehydration performance of sludge can be effectively improved, the reduction of absolute amount of the treated sludge, stacking and the like can be reduced; in addition, only fewer oxidants can be added, so that a great amount of medicaments and introduction of new pollutants can be avoided. Furthermore, a great amount of toxic and harmful substances in the sludge can be reduced, and the rapid deodorization of the sludge can be realized.

Description

technical field [0001] The invention relates to the technical field of chemical engineering, in particular to the technical field of sludge dewatering. Background technique [0002] With the rapid development of economy and society and the gradual improvement of people's quality of life, the discharge of industrial wastewater and domestic wastewater is increasing day by day. The sludge method is a process commonly used in various sewage treatment plants at present. It has the characteristics of mature technology, stable process, high treatment efficiency, and low operating costs, but it will also produce a certain amount of excess sludge at the same time, and the disposal of excess sludge The cost accounts for more than 50% of the operating cost of the entire sewage treatment plant. [0003] According to China Water Network's "China Sludge Treatment and Disposal Market Analysis Report (2013 Edition)", by 2015, my country's annual surplus sludge (containing 80% moisture)...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F11/00C02F11/06C02F11/12

Inventor 刘雅妮左卫雄颜登科

Owner KUNSHAN MAYMUSE ENVIRONMENTAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com