Recycling method for fly-ash building materials

A technology for fly ash and building materials, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as poor solidification of heavy metals, carbon dioxide gas emissions, and difficulty in finding chemicals, to ensure long-term The effect of stability, reducing leaching concentration and solving environmental safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

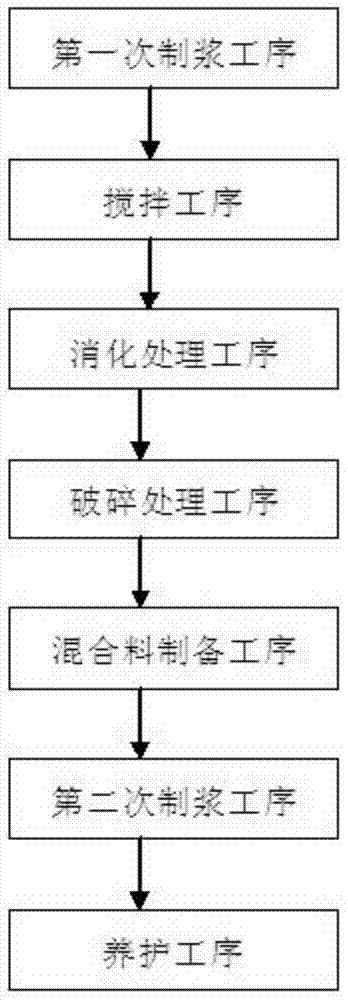

Method used

Image

Examples

Embodiment 1

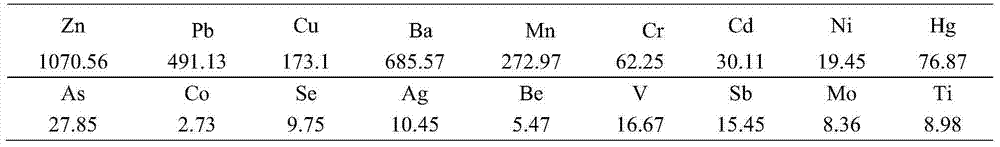

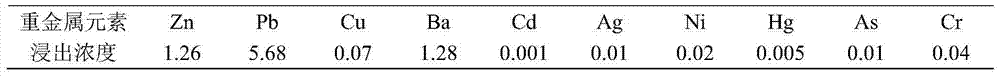

[0033] The fly ash sample comes from a waste incineration plant in Beijing. The heavy metal content in the sample is shown in Table 1-1, and the Cl content is 14.06%. From Table 1-2, it can be seen that the leaching concentration of Pb in fly ash is relatively high, which exceeds the standard limit of Pb in the "Identification Standard for Leach Concentration of Hazardous Wastes" (GB5085.3-2007), so the fly ash is judged as Hazardous waste with leaching toxicity characteristics.

[0034] Table 1-1 Content of heavy metal elements in incineration fly ash (mg / kg)

[0035]

[0036] Table 1-2 Leaching characteristics of heavy metal elements in incineration fly ash

[0037]

[0038] This fly ash building material reuse method is as follows, and can perform dechlorination and solidification and stabilization of heavy metals at the same time.

[0039] (1) Add 15% NaOH to the fly ash, add 75% water by mass percentage, and make primary mud under the condition of 25°C.

[0040] ...

Embodiment 2

[0047] The fly ash sample comes from a waste incineration plant in Chongqing. The heavy metal content in the sample is shown in Table 2-1, and the Cl content is 17.24%. It can be seen from Table 2-2 that the leaching concentration of Pb in fly ash is relatively high, which exceeds the standard limit of Pb in the "Identification Standard for Leach Concentration of Hazardous Wastes" (GB5085.3-2007), so the fly ash is judged as Hazardous waste with leaching toxicity characteristics.

[0048] Table 2-1 Content of heavy metal elements in incineration fly ash (mg / kg)

[0049]

[0050] Table 2-2 Leaching characteristics of heavy metal elements in incineration fly ash

[0051]

[0052] This fly ash building material reuse method is as follows, and can perform dechlorination and solidification and stabilization of heavy metals at the same time.

[0053] (1) Add 20% NaOH to fly ash, add 100% water by mass percentage, and make primary mud under the condition of 25°C.

[0054] (2...

Embodiment 3

[0061] The fly ash sample comes from a waste incineration plant in Beijing. The heavy metal content in the sample is shown in Table 3-1, and the Cl content is 14.06%. It can be seen from Table 3-2 that the leaching concentration of Pb in fly ash is relatively high, which exceeds the standard limit of Pb in the "Identification Standard for Leach Concentration of Hazardous Wastes" (GB5085.3-2007), so the fly ash is judged as Hazardous waste with leaching toxicity characteristics.

[0062] Table 3-1 Content of heavy metal elements in incineration fly ash (mg / kg)

[0063]

[0064] Table 3-2 Leaching characteristics of heavy metal elements in incineration fly ash

[0065]

[0066] This fly ash building material reuse method is as follows, and can perform dechlorination and solidification and stabilization of heavy metals at the same time.

[0067] (1) Add 6% Na to the fly ash 2 SiO 3 , add water with a mass percentage of 50%, and make primary mud under the condition of 25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com