A cobalt-based alloy used for sheathed thermocouple cables

An armored thermocouple, cobalt-based alloy technology, applied in the field of alloys, can solve the problems of inability to make armored thermocouple deep-processed products, reduce the strength and plasticity of alloys, and limit the scope of application, so as to solve technical defects and use restrictions, improve The effect of stability and improvement of anti-oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

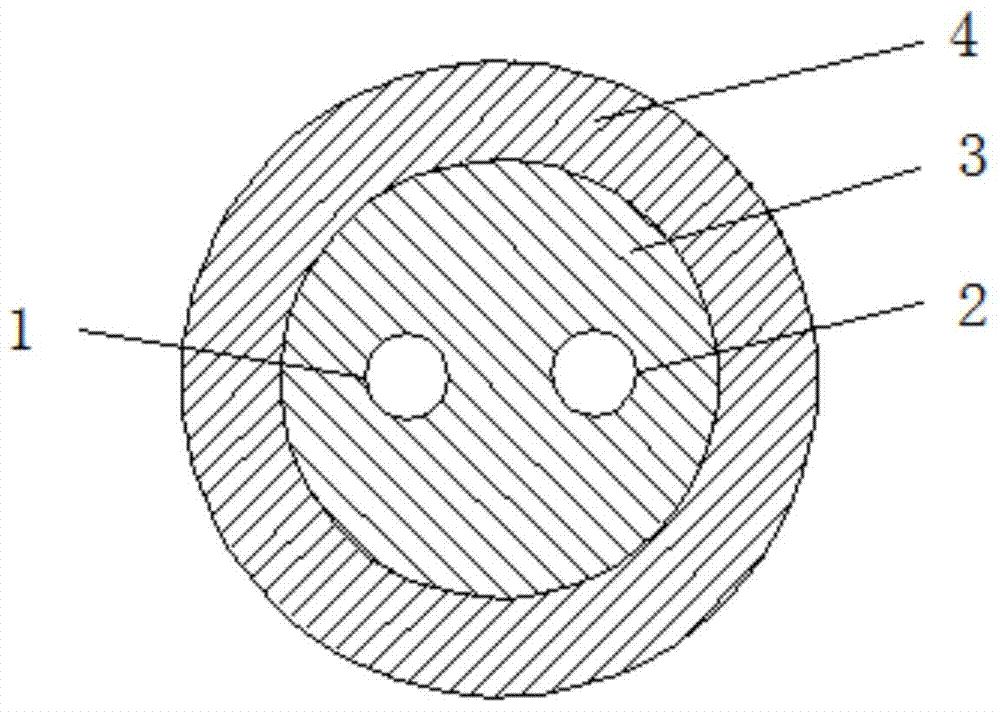

[0015] Embodiment 1 In the present invention, the positive and negative thermocouple wires of the N-type armored thermocouple cable: the metal sleeve 4 prepared by nickel-chromium-silicon-nickel-silicon-magnesium and cobalt-based alloys are cleaned, and the positive poles of the thermocouple wires are cleaned. 1 and the negative electrode 2 are penetrated into the insulator material 3, and then penetrated into the cobalt-based alloy metal sleeve, and are prepared through drawing, diameter reduction, and heat treatment processes. The prepared armored thermocouple cable has an outer diameter of Φ12.7mm and a service temperature of 1100°C. After testing, the thermal stability of the armored thermocouple at this temperature is <1.0°C / 250h, and the working frequency withstand voltage is 500VAC / min without breakdown. .

Embodiment 2

[0016] Embodiment 2 In the present invention, the positive and negative thermocouple wires of the K-type armored thermocouple cable are cleaned from the metal sleeve 4 prepared by nickel-chromium-nickel-aluminum and cobalt-based alloys, and the positive electrodes 1 and 1 of the thermocouple wires are cleaned. The negative electrode 2 is penetrated into the insulator material 3, and then penetrated into the cobalt-based alloy metal sleeve, and is prepared through drawing, diameter reduction, and heat treatment processes. The outer diameter of the prepared armored thermocouple cable is Φ0.5mm, and the operating temperature is 1200°C. After testing, the thermal stability of the armored thermocouple at this temperature is <2.0°C / 250h, and the working frequency withstand voltage is 500VAC / min without breakdown. .

Embodiment 3

[0017] Embodiment 3 In the present invention, the positive and negative thermocouple wires of the K-type armored thermocouple cable are cleaned from the metal sleeve 4 prepared by nickel-chromium-nickel-silicon and cobalt-based alloys, and the positive electrodes 1 and 1 of the thermocouple wires are cleaned. The negative electrode 2 is penetrated into the insulator material 3, and then penetrated into the cobalt-based alloy metal sleeve, and is prepared through drawing, diameter reduction, and heat treatment processes. The outer diameter of the prepared armored thermocouple cable is Φ1.5mm, and the operating temperature is 1150°C. After testing, the thermal stability of the armored thermocouple at this temperature is <1.5°C / 250h, and the working frequency withstand voltage is 500VAC / min without breakdown. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com