Natural silk facial mask base cloth and preparation method thereof

A natural silk and facial mask technology, applied in non-woven fabrics, silk fiber production, fabric surface trimming, etc., can solve the problems of high processing cost, waste of sericin protein, waste of resources, etc., achieve short processing process and increase hydrophilicity , the effect of improving softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

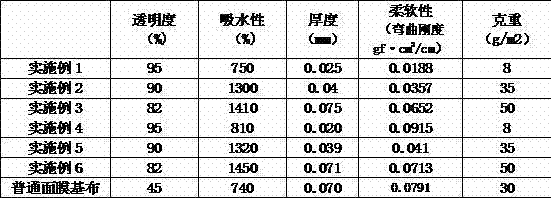

Examples

Embodiment 1

[0041] 1. Preparation of flat silk sheet

[0042] Put the mature and uniform silkworms on the flat spinning net, the size of the spinning net is 2m x 1m in length and width, and the amount of cooked silkworms is 500 heads / square meter. , Catch the cooked silkworms on another flat silk spinning net to continue spinning, and so forth until the silk spinning stops.

[0043] 2. Degreasing and softening treatment

[0044] 1) Use an aqueous solution with a bath ratio of 1:90, in which the amount of deoiling spirit is 0.05%, Na 2 CO 3 The dosage is 0.05%, the dosage of penetrant JFC is 0.2%, the treatment temperature is 40℃, the treatment time is 50min, and then washed with water until the pH value is neutral;

[0045] 2) Use an aqueous solution with a bath ratio of 1:120, in which the amount of softener is 0.8%, the amount of glacial acetic acid is 0.2%, the treatment temperature is 40°C, the treatment time is 60 minutes, and then washed with water until the pH value is neutr...

Embodiment 2

[0052] 1. Preparation of flat silk sheet

[0053] Put the mature and uniform silkworms on the flat spinning net. The size of the spinning net is 2m x 1m in length and width. The amount of cooked silkworms is 600 heads / square meter. , Catch the cooked silkworms on another flat silk spinning net to continue spinning, and so forth until the silk spinning stops.

[0054] 2. Degreasing and softening treatment

[0055] 1) Use an aqueous solution with a bath ratio of 1:90, in which the amount of deoiling spirit is 0.1%, Na 2 CO 3 The dosage is 0.1%, the dosage of penetrant JFC is 0.4%, the treatment temperature is 50℃, the treatment time is 60min, and then washed with water until the pH value is neutral;

[0056] 2) Use an aqueous solution with a bath ratio of 1:120, in which the amount of softener is 1.2%, the amount of glacial acetic acid is 0.6%, the treatment temperature is 50°C, the treatment time is 70 minutes, and then washed with water until the pH value is neutral;

...

Embodiment 3

[0063] 1. Preparation of flat silk sheet

[0064] Put the mature and uniform silkworms on the flat spinning net, the size of the spinning net is 2m x 1m, and the amount of cooked silkworms is 700 heads / square meter. When the silk spinning amount of cooked silkworms reaches 50 g / square , Catch the cooked silkworms on another flat silk spinning net to continue spinning, and so forth until the silk spinning stops.

[0065] 2. Degreasing and softening treatment

[0066] 1) Use an aqueous solution with a bath ratio of 1:90, in which the amount of deoiling spirit is 0.3%, Na 2 CO 3 The dosage is 0.2%, the dosage of penetrant JFC is 0.6%, the treatment temperature is 60℃, the treatment time is 70min, and then washed with water until the pH value is neutral;

[0067] 2) Use an aqueous solution with a bath ratio of 1:120, in which the amount of softener is 2%, the amount of glacial acetic acid is 1%, the treatment temperature is 60°C, the treatment time is 80 minutes, and then w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com