Water-based lubricant for paper making

A lubricant and water-based technology, which is applied in papermaking, textiles and papermaking, and fiber raw material treatment, can solve the problems of carcinogenicity, insignificant lubricant comprehensive effect, and poisonous epichlorohydrin, so as to improve stability and reduce friction. Observe the coefficient and improve the effect of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

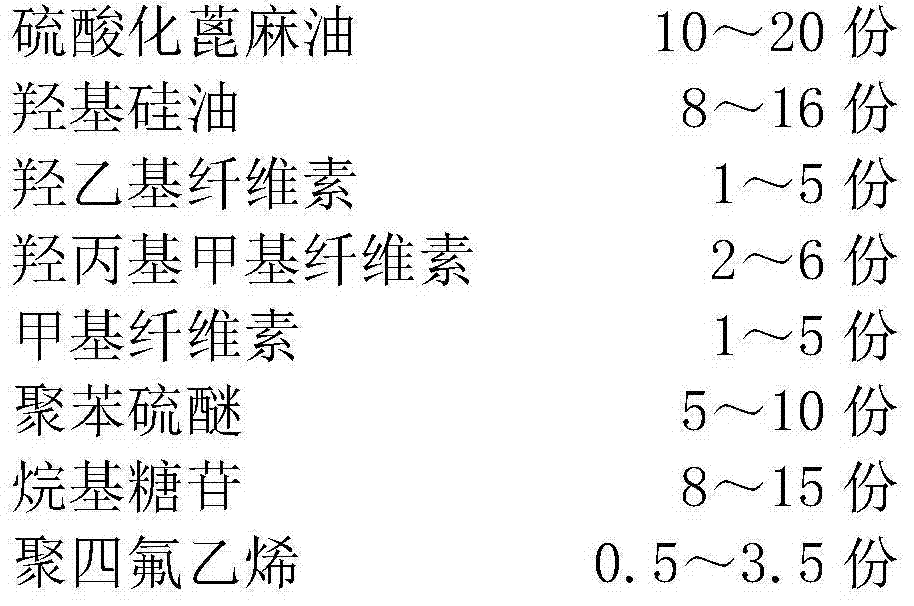

[0021] Water-based lubricant for papermaking, made of the following raw materials in parts by weight:

[0022]

[0023] Its preparation method is:

[0024] Put water into a stirring tank, heat up to 40°C, add sodium diacetate, stir evenly, then add hydroxyethyl cellulose, hydroxypropyl methyl cellulose and methyl cellulose while stirring, continue stirring until completely dissolved , and then sequentially add sulfated castor oil, hydroxyl silicone oil, polyphenylene sulfide, alkyl glycoside and polytetrafluoroethylene, and stir evenly.

Embodiment 2

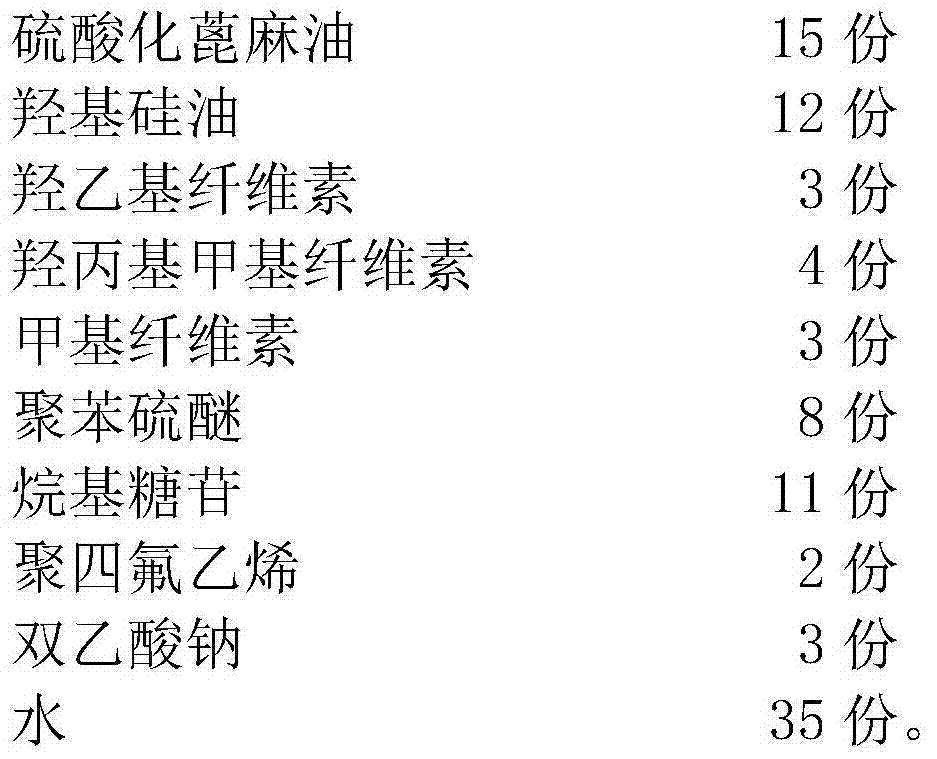

[0026] Water-based lubricant for papermaking, made of the following raw materials in parts by weight:

[0027]

[0028] Its preparation method is:

[0029] Put water into a stirring tank, heat up to 43°C, add sodium diacetate, stir evenly, then add hydroxyethyl cellulose, hydroxypropyl methyl cellulose and methyl cellulose while stirring, continue stirring until completely dissolved , and then sequentially add sulfated castor oil, hydroxyl silicone oil, polyphenylene sulfide, alkyl glycoside and polytetrafluoroethylene, and stir evenly.

Embodiment 3

[0031] Water-based lubricant for papermaking, made of the following raw materials in parts by weight:

[0032]

[0033] Its preparation method is:

[0034] Put water into a stirring tank, heat up to 45°C, add sodium diacetate, stir evenly, then add hydroxyethyl cellulose, hydroxypropyl methyl cellulose and methyl cellulose while stirring, continue stirring until completely dissolved , and then sequentially add sulfated castor oil, hydroxyl silicone oil, polyphenylene sulfide, alkyl glycoside and polytetrafluoroethylene, and stir evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com