Fuel cell operation technology for improving regeneration rate and electricity generating efficiency of complex iron in desulfuration process

A fuel cell, regeneration rate technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of slow regeneration, low battery coulomb efficiency, etc., to achieve the effect of electric energy recovery promotion, process energy saving and environmental protection, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

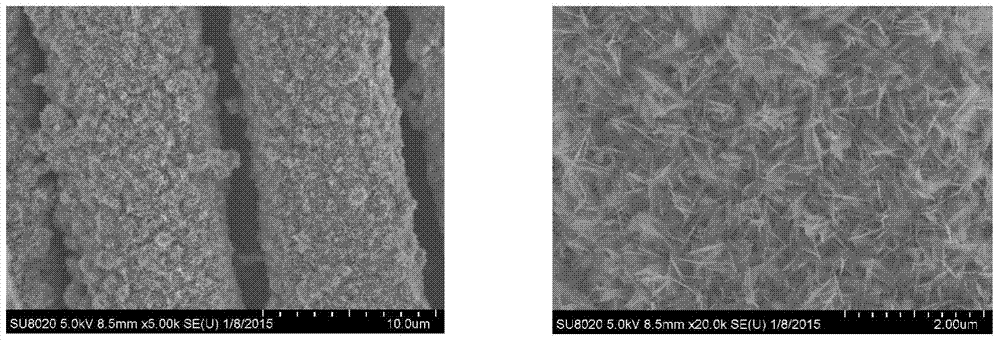

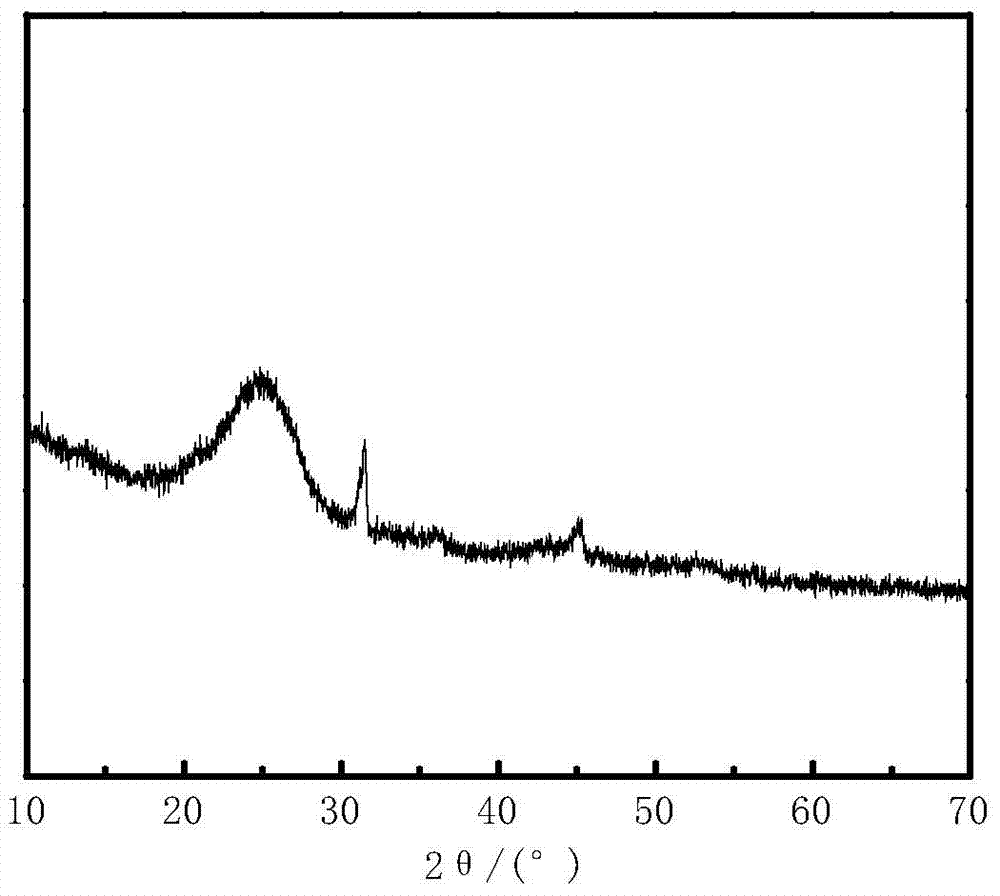

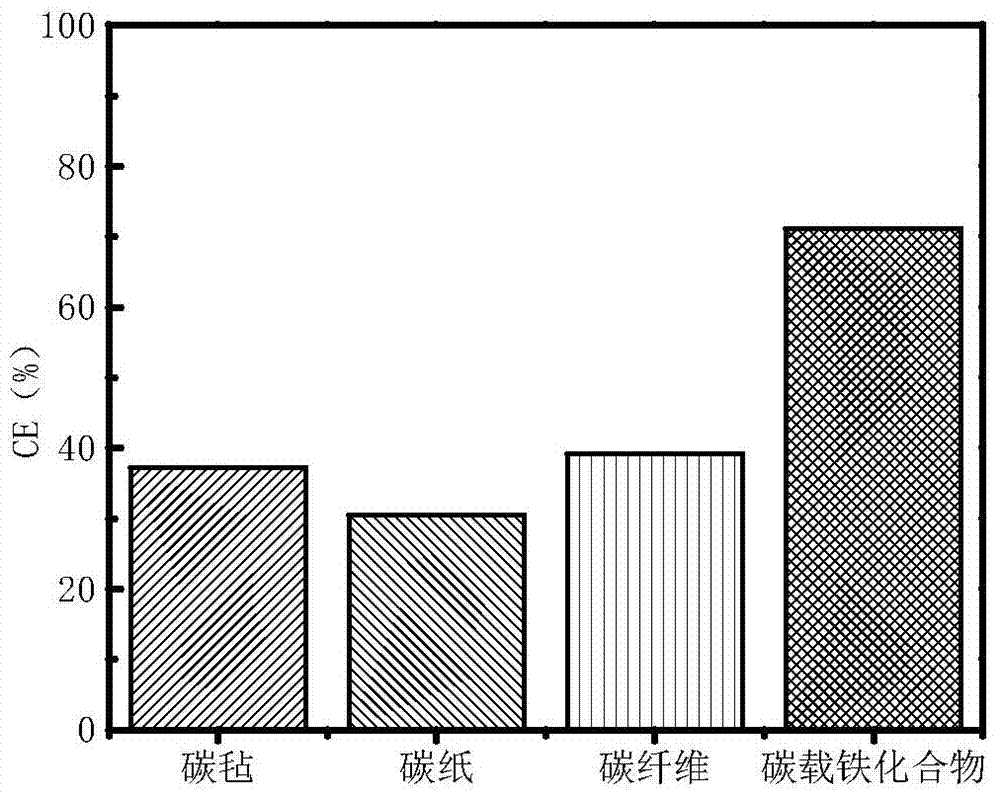

Embodiment 1

[0022] In the air cathode fuel cell, the carbon fiber is the anode of the battery, and the desulfurized iron complex solution with a pH value of 8 is added, and its composition is 1 mmol L -1 FeCl 2 , 2mmol·L -1 NTA, 0.2mol L -1 Sodium bicarbonate, 0.2mol·L -1 NaCl, use 1mol L under nitrogen atmosphere -1 The pH of the solution was adjusted to 10.5 with NaOH, and the cell was closed. The cathode and anode of the battery are connected with wires, and a 1kΩ resistor is connected in the middle to measure the voltage across the resistor. When the voltage drops to zero, the circuit is disconnected, and the nanometer Fe(III) compound catalyst is loaded on the anode of the battery in situ. Replace the solution in the battery with the complex iron solution after desulfurization, connect the circuit, and take samples to measure Fe in real time. 2+ concentration. When the voltage drop is 1mv, the circuit is disconnected, and the calculated coulombic efficiency of the battery is 7...

Embodiment 2

[0024] In the air cathode fuel cell, the carbon felt is the anode of the battery, and the complex iron solution after desulfurization with a pH value of 6 is added, and its composition is 10mmol L -1 FeSO 4 , 10mmol·L -1 NTA, 0.2mol L -1 Sodium bicarbonate, use 1mol L under nitrogen atmosphere -1 The pH of the solution was adjusted to 9 with NaOH, and the cell was closed. The cathode and anode of the battery are connected with wires, and a 1kΩ resistor is connected in the middle to measure the voltage across the resistor. When the voltage drops to about zero, the circuit is disconnected, and the nanometer Fe(III) compound catalyst is loaded on the anode of the battery in situ. Replace the solution in the battery with the complex iron solution after desulfurization, connect the circuit, and take samples to measure Fe in real time. 2+ concentration. When the voltage drop is 1mv, the circuit is disconnected, and the calculated coulombic efficiency of the battery is 67%, and...

Embodiment 3

[0026] In the air cathode fuel cell, the carbon paper is the anode of the battery, and the complex iron solution after desulfurization with a pH value of 7.5 is added, and its composition is 30mmol L -1 Molar salt, 15mmol·L -1 EDTA, 0.2mol L -1 Sodium bicarbonate, 0.2mol·L -1 Na 2 SO 4 , use 1mol·L under nitrogen atmosphere -1 The pH of the solution was adjusted to 12 with NaOH, and the cell was closed. The cathode and anode of the battery are connected with wires, and a 1kΩ resistor is connected in the middle to measure the voltage across the resistor. When the voltage drops to about zero, the circuit is disconnected, and the nanometer Fe(III) compound catalyst is loaded on the anode of the battery in situ. Replace the solution in the battery with the complex iron solution after desulfurization, connect the circuit, and take samples to measure Fe in real time. 2+ concentration. When the voltage drop is 1mv, the circuit is disconnected, and the calculated coulombic eff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com