Thermoplastic resin composition and molded product thereof

A technology of thermoplastic resin and composition, applied in the field of thermoplastic resin composition and its molded body, can solve the problems of high cost, difficulty in obtaining high-quality appearance of piano black, environmental pollution and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0274] Using a twin screw extruder ("TEM-58SS" manufactured by Toshiba Machine Co., Ltd.), the thermoplastic resin composition was produced as follows.

[0275] The supply port is provided at one place on the upstream side, and supplies the components (a), (B), (C), and (D) that have been sufficiently dried to remove moisture.

[0276] The barrel temperature of the extruder at this time was set to 250°C throughout.

[0277] In addition, the discharge amount of the kneaded product at this time was 300 kg / hour, and the screw rotation speed was 250 rpm.

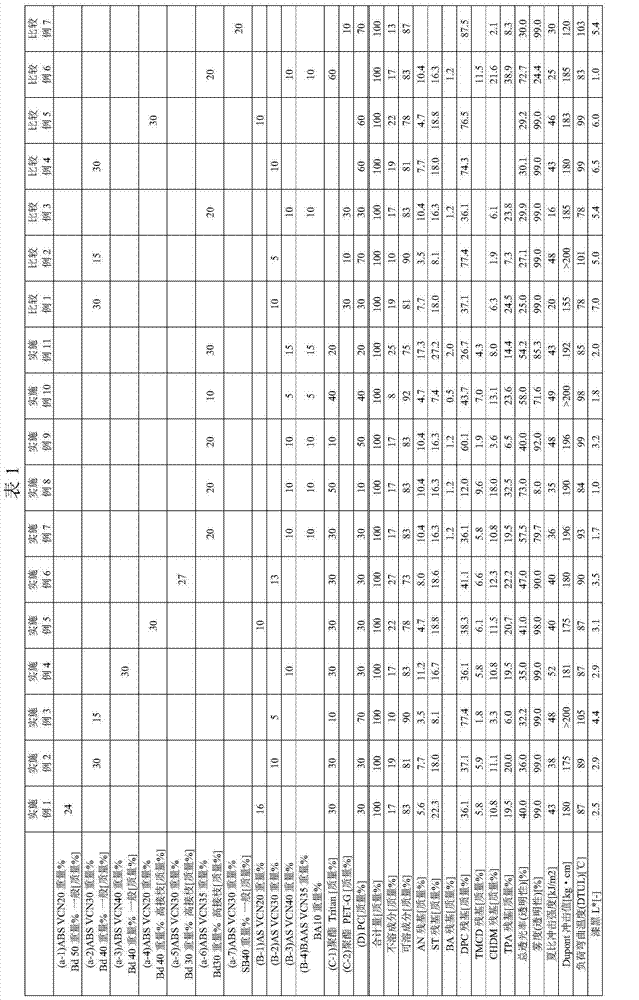

[0278] The types and mixing ratios of the raw materials at this time are shown in Table 1 for example.

[0279] Using the obtained pellets, the aforementioned evaluations were performed. The results are shown in Table 1.

Embodiment 2、4~7

[0281] As the component (a), components having different blending amounts and grafting ratios of vinyl cyanide monomers are supplied.

[0282] In addition, the materials shown in Table 1 below were used as the (B) component, and the addition amounts of the (C) component and (D) component were appropriately adjusted. The other conditions were the same as in Example 1, and pellets were obtained.

[0283] Using the obtained pellets, the aforementioned evaluations were performed. The results are shown in Table 1.

Embodiment 3

[0285] The components shown in Table 1 below were used as (a), (B), (C), and (D) components, and the addition amount was adjusted. The other conditions were the same as in Example 1, and pellets were obtained.

[0286] Using the obtained pellets, the aforementioned evaluations were performed. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com