Patents

Literature

56 results about "2,2,4,4-Tetramethyl-1,3-cyclobutanediol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

2,2,4,4-Tetramethyl-1,3-cyclobutanediol (CBDO) is an aliphatic diol. This diol is produced as a mixture of cis- and trans-isomers, depending on the relative stereochemistry of the hydroxyl groups. It is used as a monomer for the synthesis of polymeric materials. CBDO is currently being researched as an alternative to bisphenol A (BPA). BPA is a precursor used in the production of a wide range of polymers including polycarbonates, polyesters, polysulfones, and polyester ketones.

Multilayered, transparent articles containing polyesters comprising a cyclobutanediol and a process for their preparation

InactiveUS20060234073A1Easy to processImprove propertiesBottlesSynthetic resin layered productsPolyesterPolymer science

Disclosed are transparent, multilayered articles having high transparency and low haze and a process for their preparation. The multilayer articles comprise at least one layer which contains at least one polyester comprising 2,2,4,4-tetramethyl-1,3-cyclobutanediol and a separate layer which contains copolyamide or homogeneous blend of polyamides. The polyester component and the polyamide component have refractive indices which differ by about 0.006 to about −0.0006. The small difference in the refractive indices enable the incorporation of regrind into one or more of the layers of the article while maintaining high clarity. These articles can exhibit improved excellent barrier properties and good melt processability while retaining excellent mechanical properties. Metal catalysts can be incorporated into one or more layers to impart oxygen-scavenging properties.

Owner:EASTMAN CHEM CO

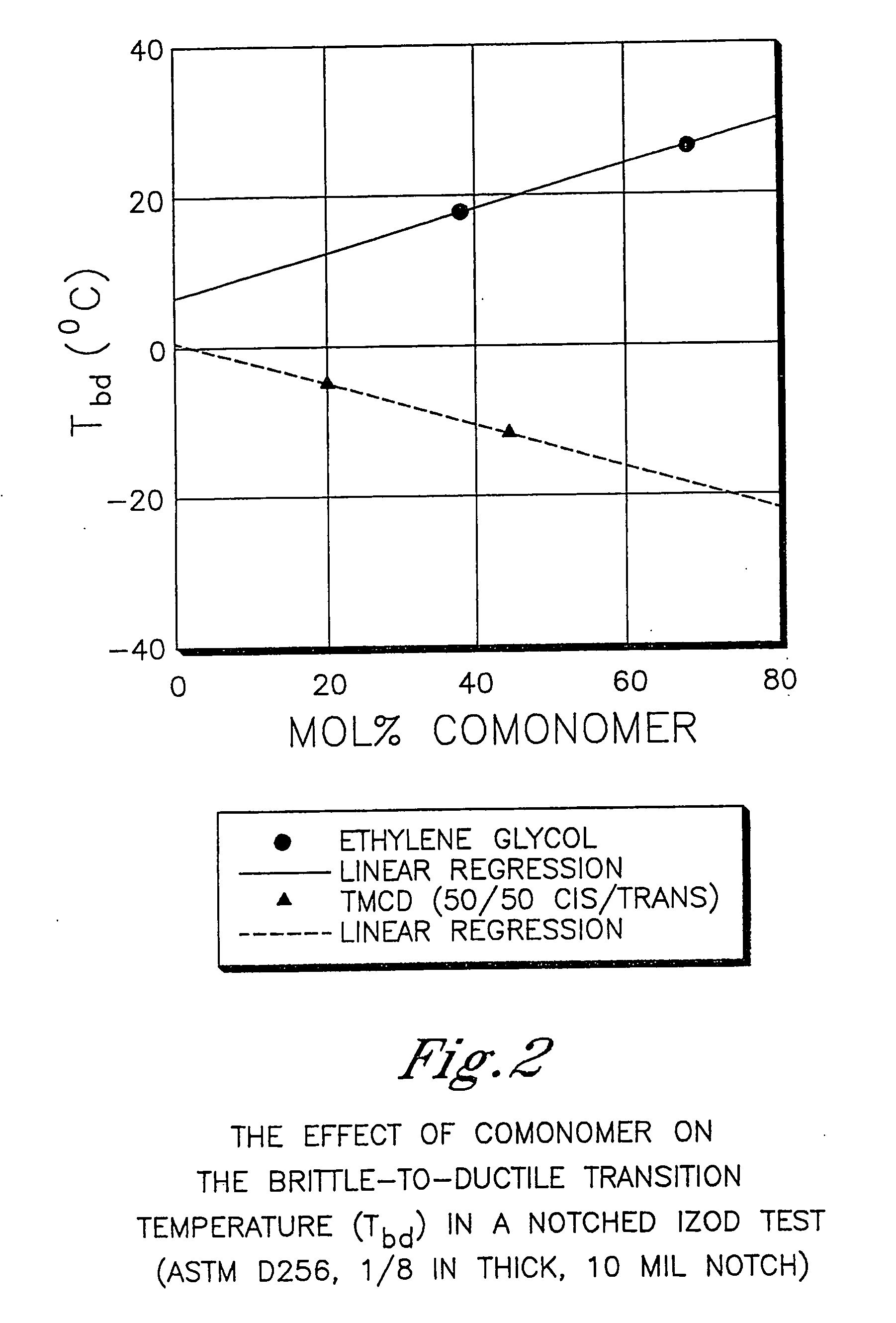

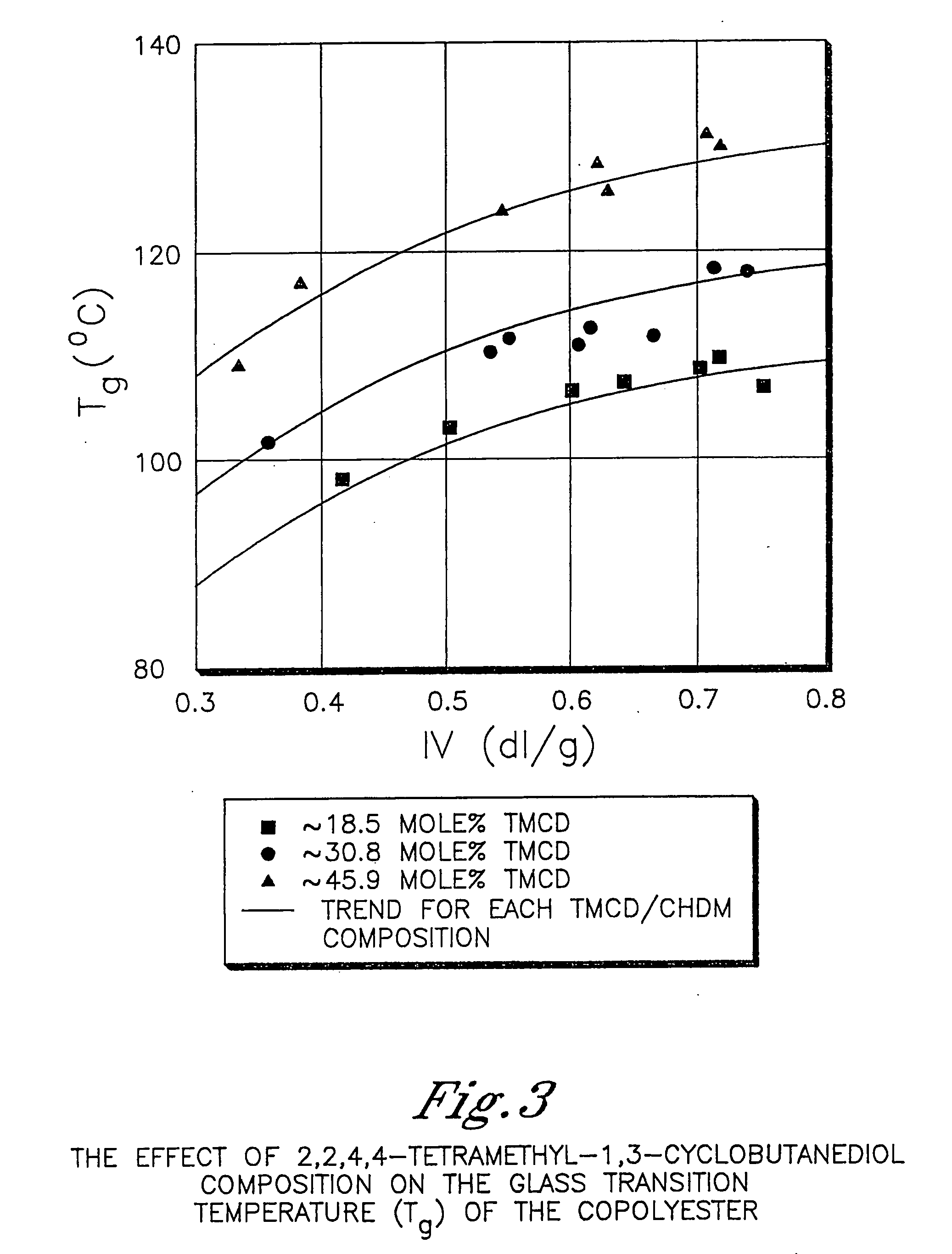

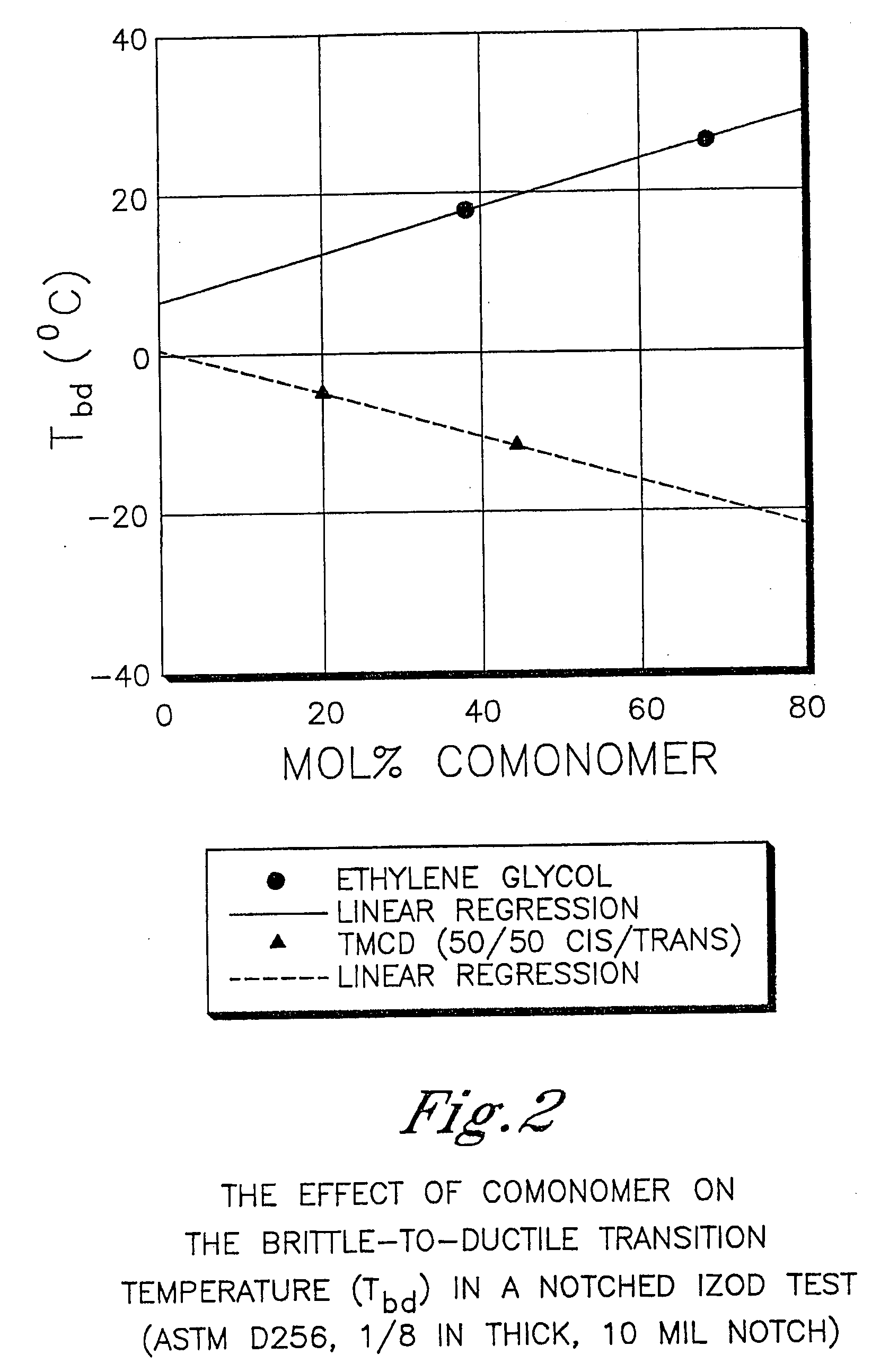

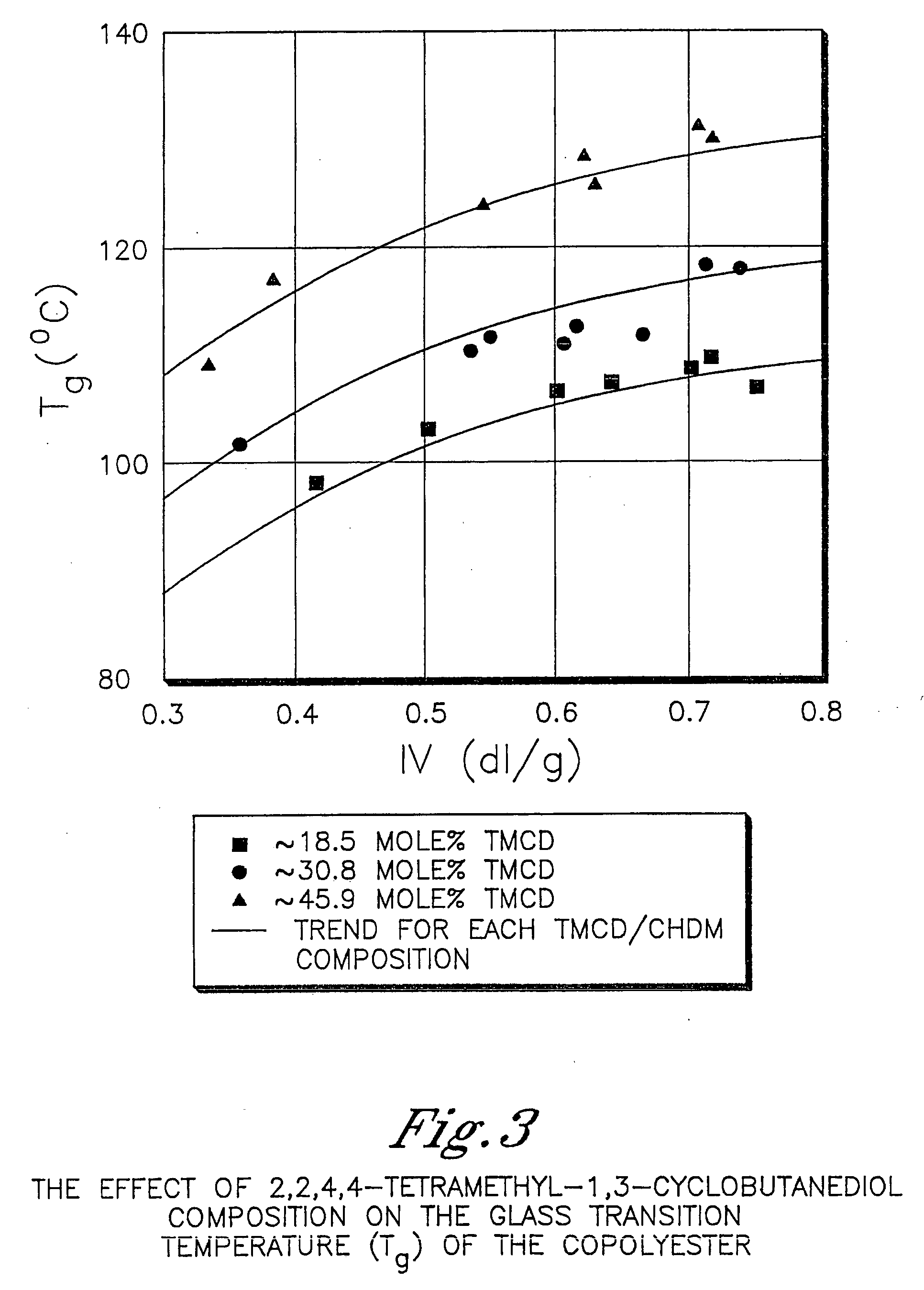

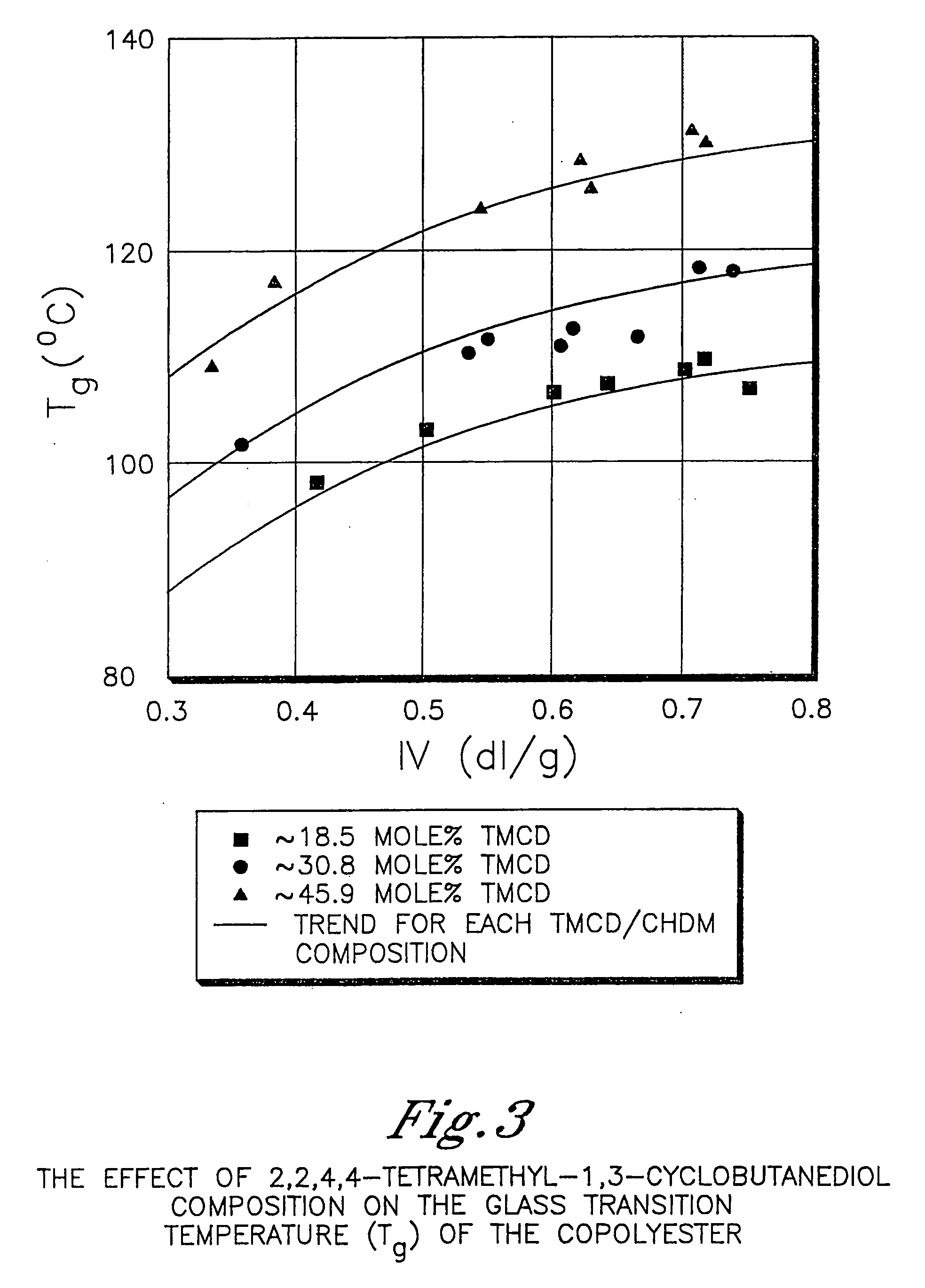

Polyester compositions containing cyclobutanediol having a certain combination of inherent viscosity and high glass transition temperature and articles made therefrom

ActiveUS20060287482A1Good chemical resistanceHigh impact strengthDialysis systemsDialysisFiberPolymer science

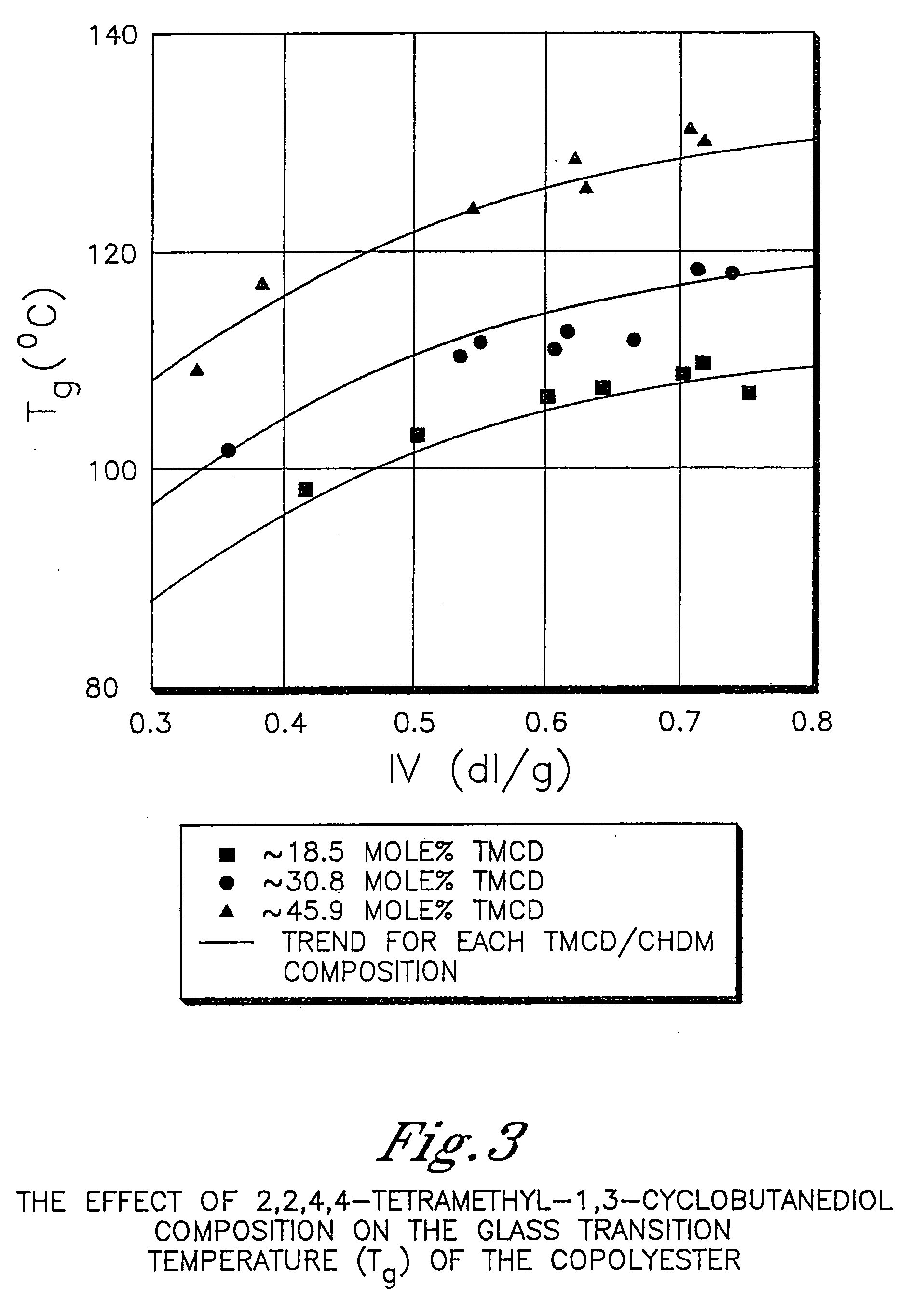

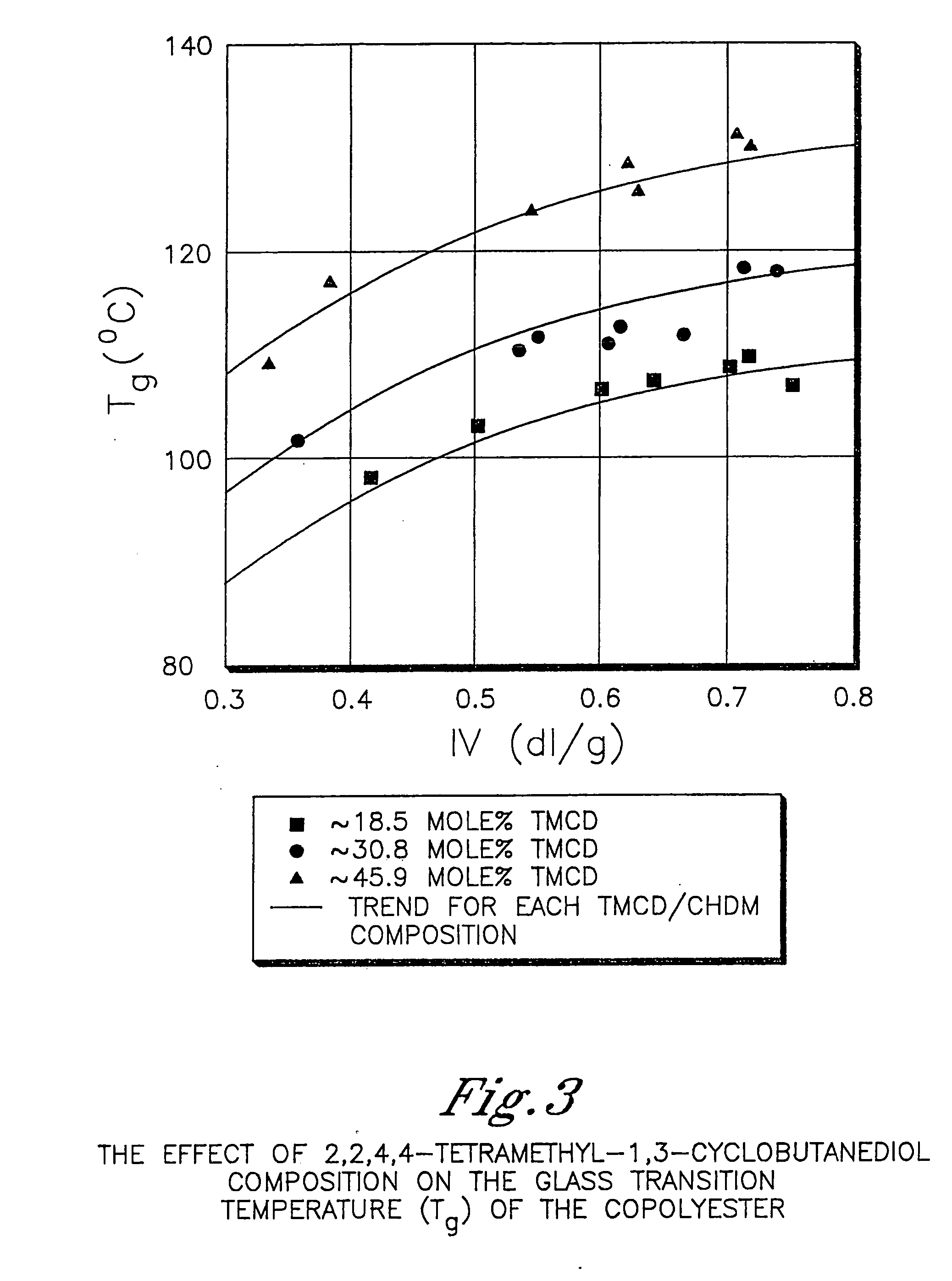

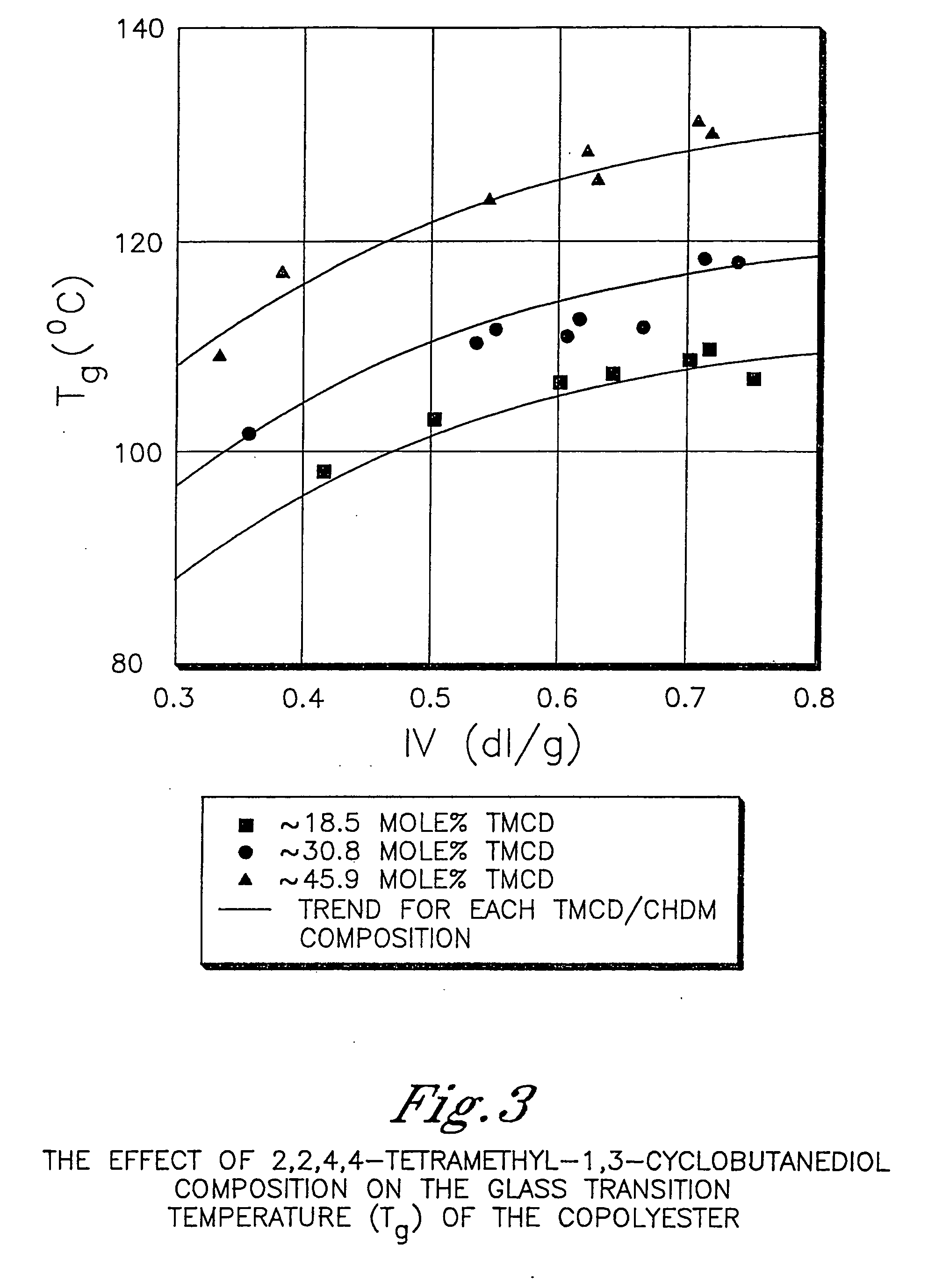

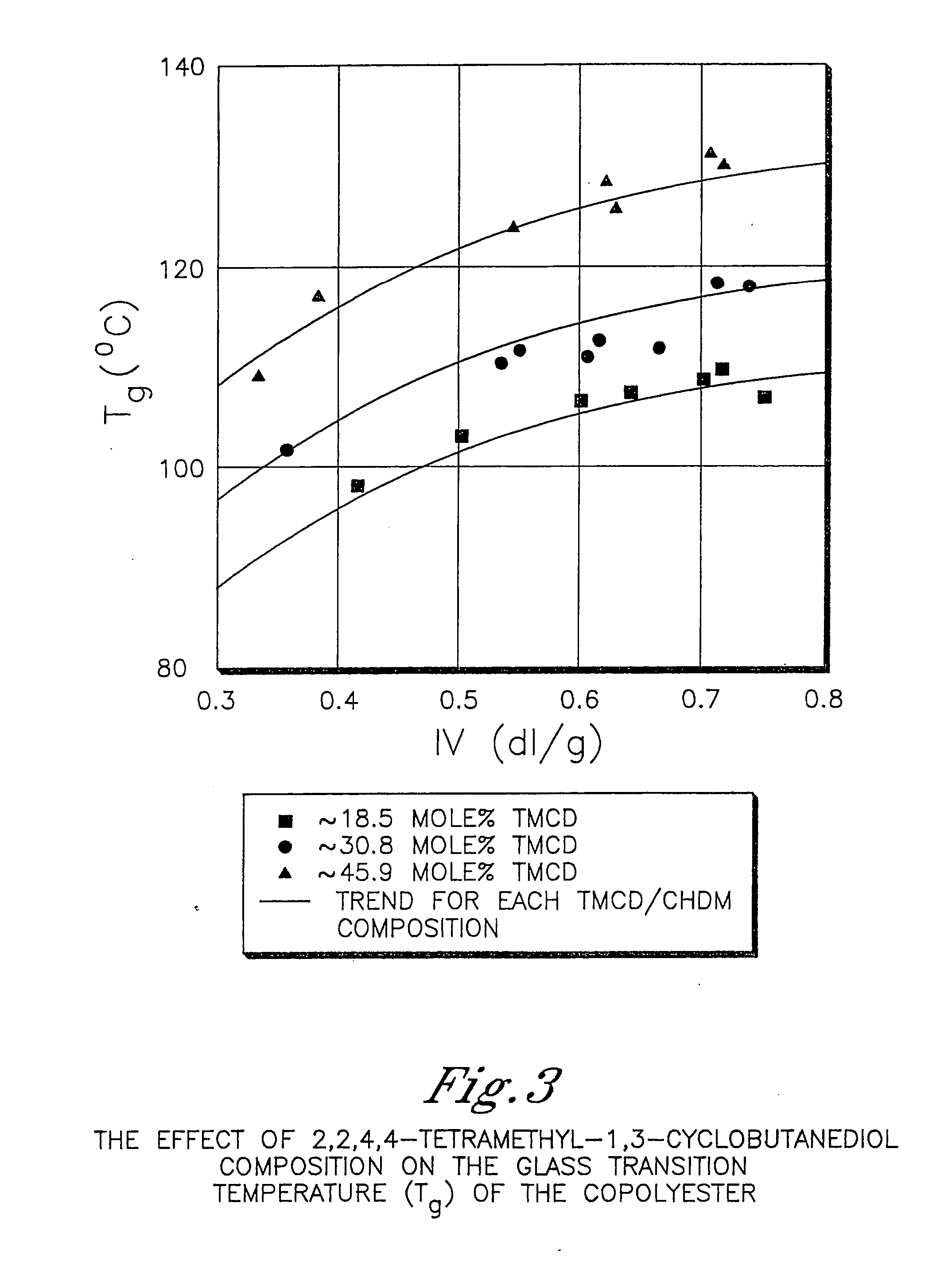

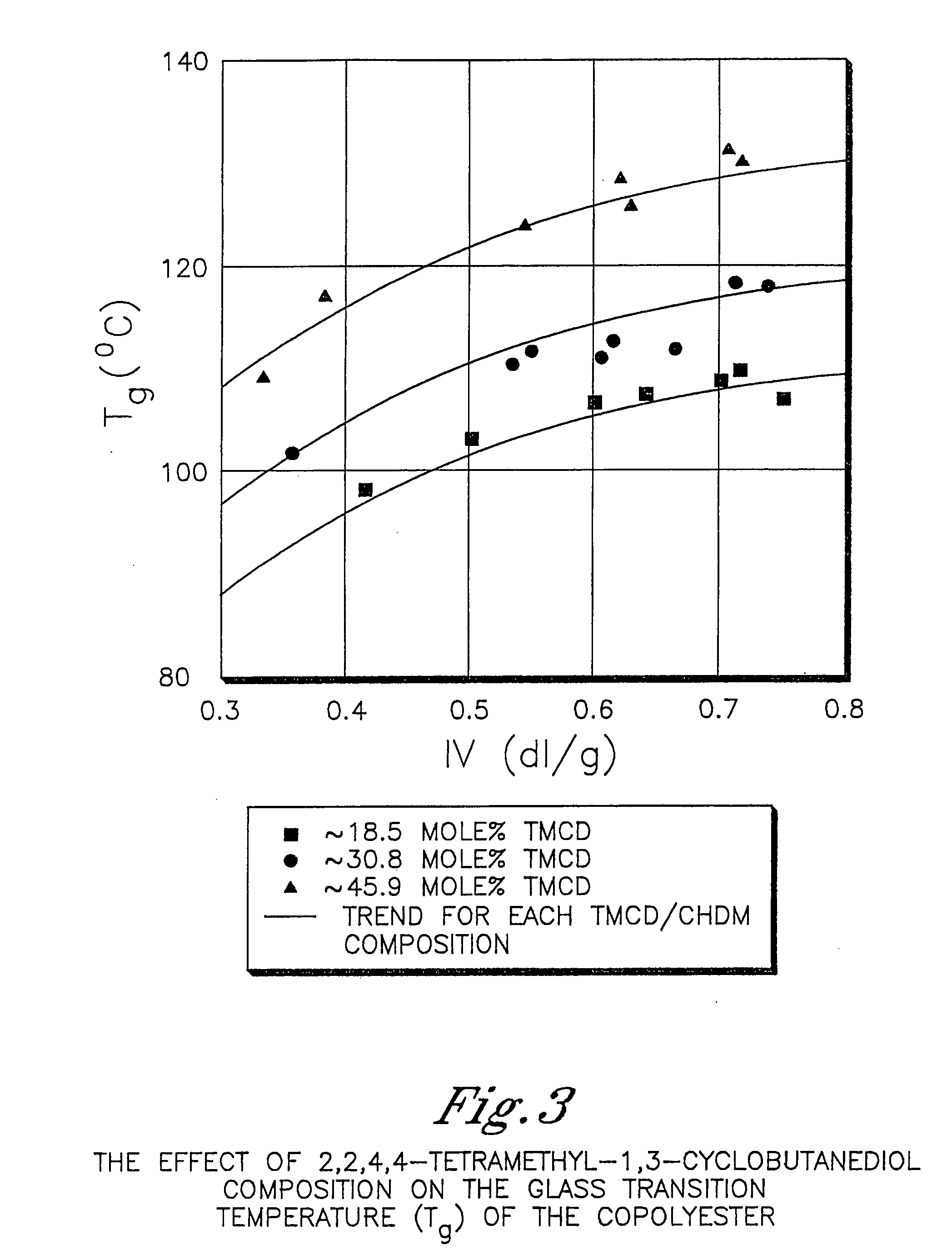

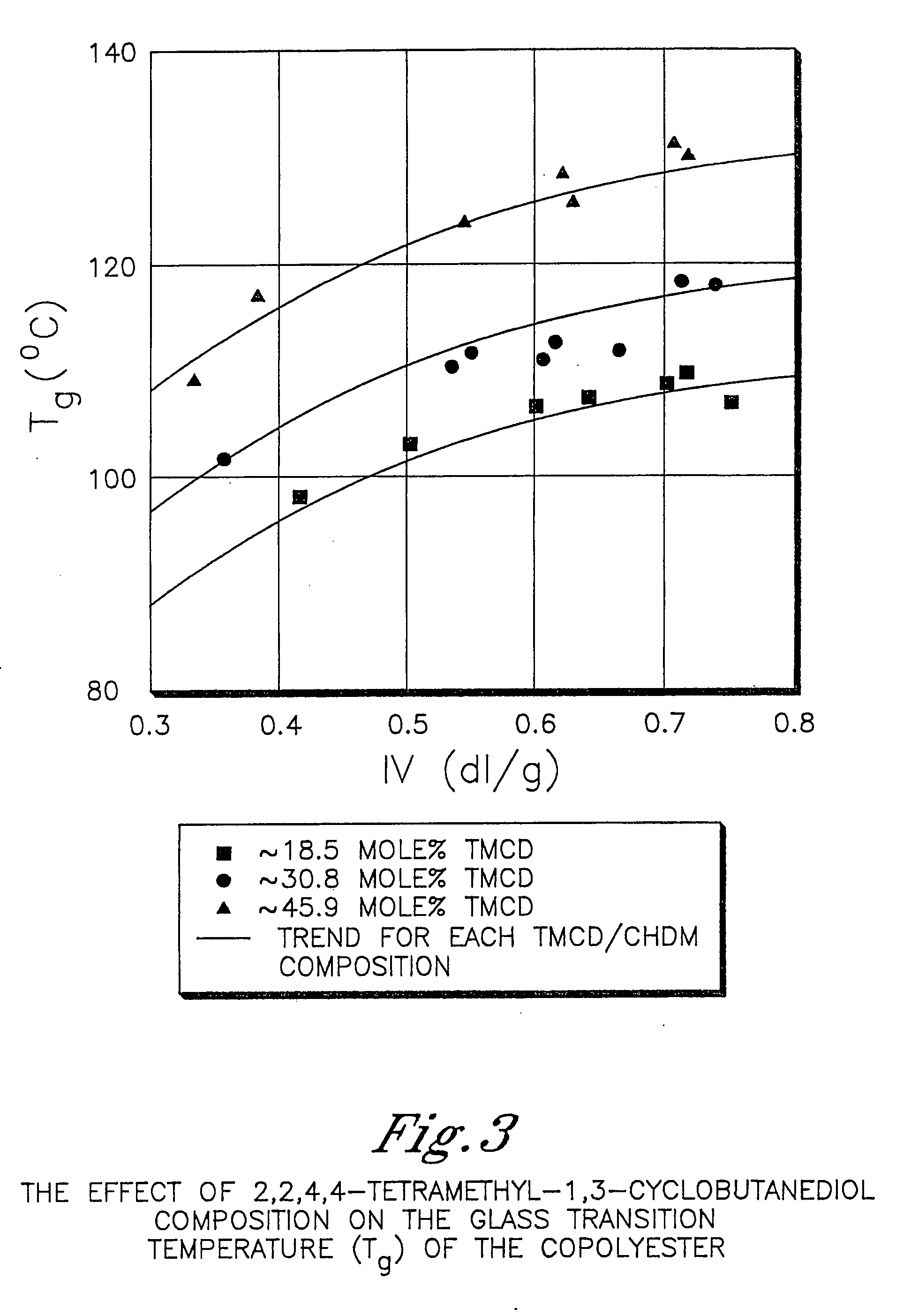

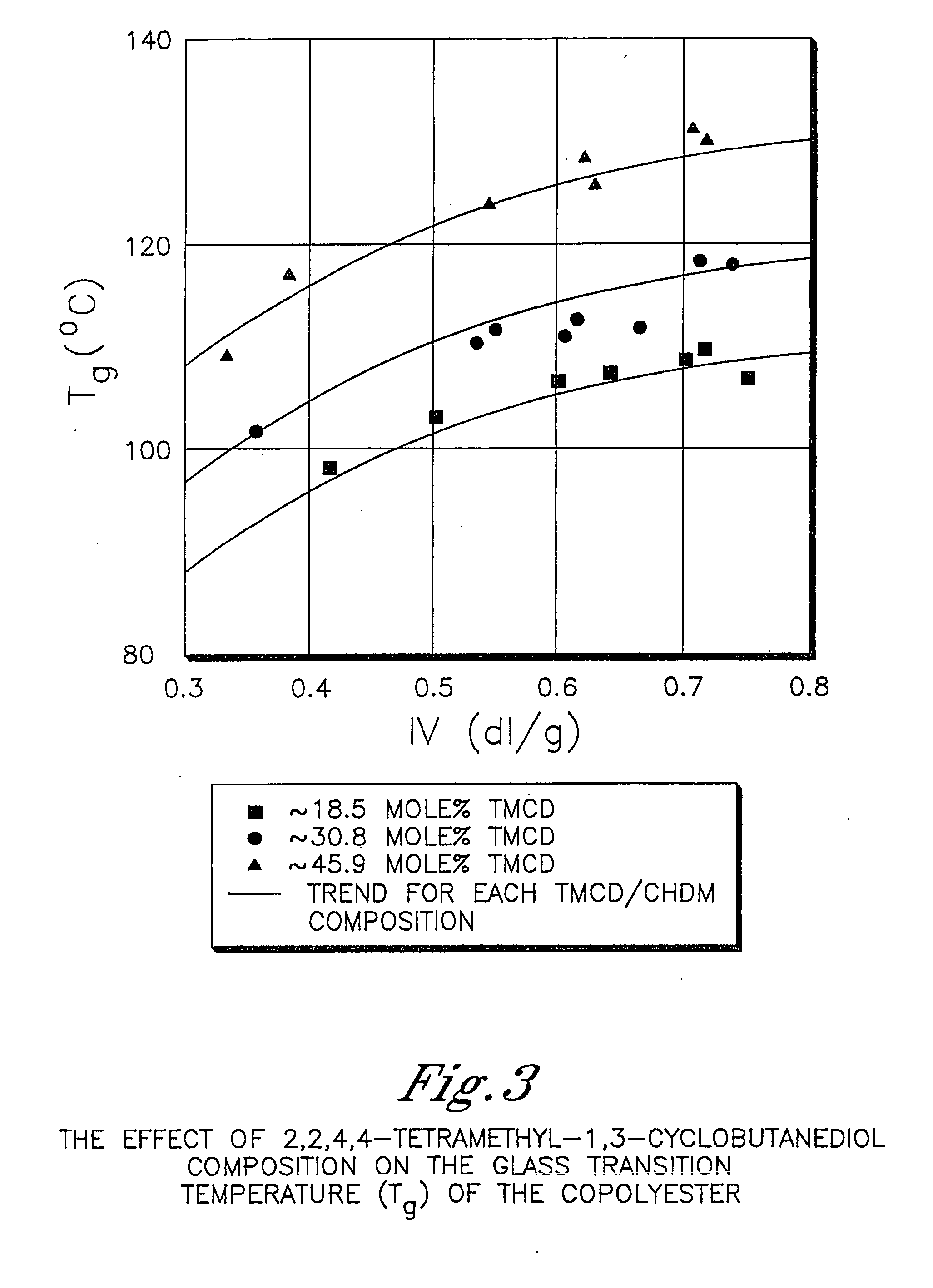

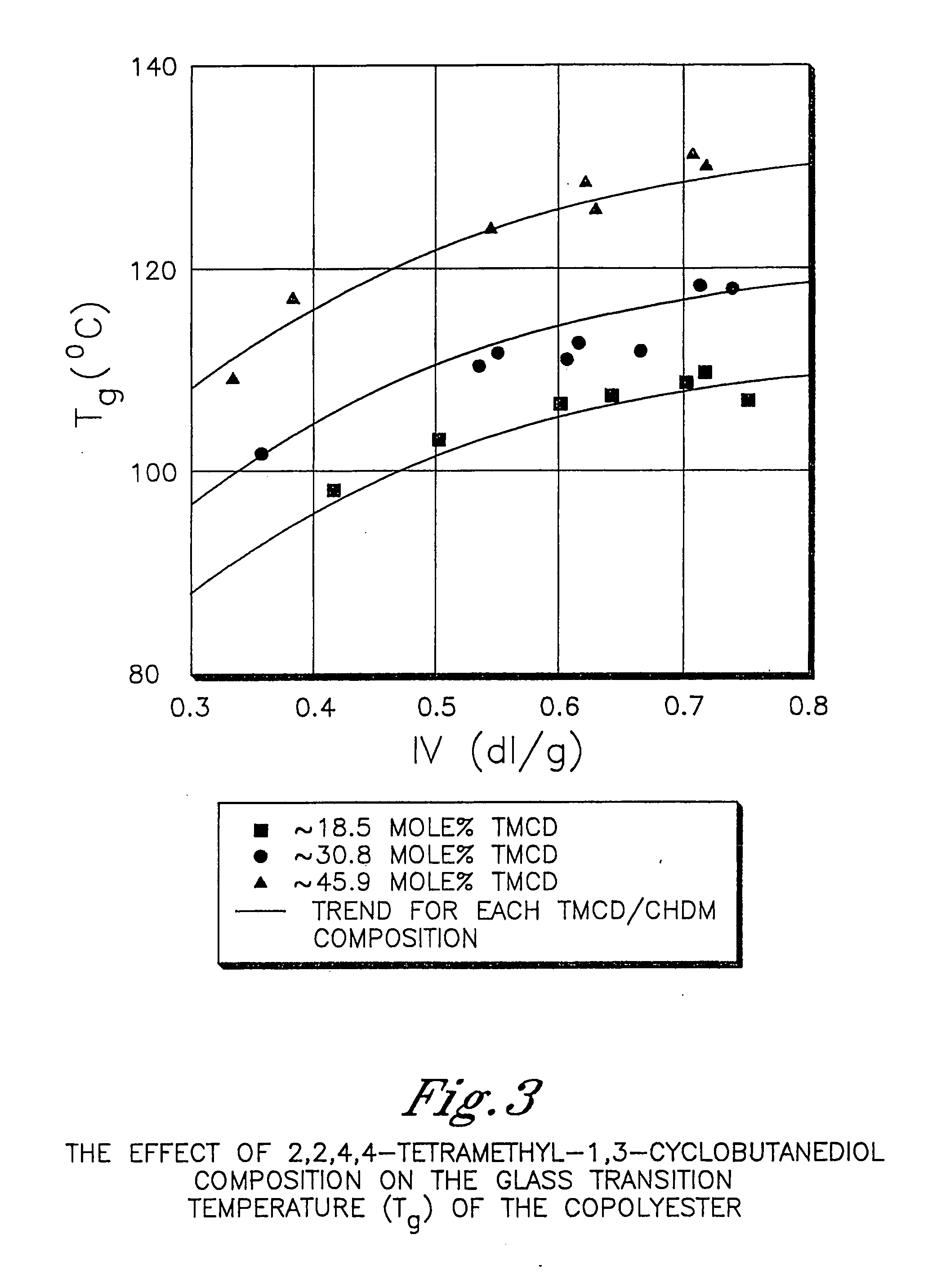

Described are polyester compositions comprising at least one polyester which comprises terephthalic acid residues, 2,2,4,4-tetramethyl-1,3-cyclobutanediol, and 1,4-cyclohexanedimethanol, wherein the inherent viscosity and the Tg of the polyester provides for certain polyester properties. The polyesters may be manufactured into articles such as fibers, films, bottles or sheets.

Owner:EASTMAN CHEM CO

Polyester compositions containing furandicarboxylic acid or an ester thereof, and 2,2,4,4-tetramethyl-1,3-cyclobutanediol

ActiveUS20130095263A1High glass transition temperatureBottlesSynthetic resin layered productsFiberPolyester

Described are polyesters comprising (a) a dicarboxylic acid component comprising 2,5-furandicarboxylic acid residues; optionally, aromatic dicarboxylic acid residues and / or modifying aliphatic dicarboxylic acid residues and 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues. The polyesters may be manufactured into articles such as fibers, films, bottles, coatings, or sheets.

Owner:EASTMAN CHEM CO

Graphic art films comprising polyester compositions formed from 2,2,4,4-tetramethyl-1,3-cyclobutanediol and 1,4-cyclohexanedimethanol

InactiveUS20060287474A1Inherent glass transition temperatureInherent viscosityDialysis systemsDialysisDicarboxylic acidCarboxylic acid

Described are graphic art films comprising polyester compositions comprising polyesters which comprise (a) a dicarboxylicacidcomponent having terephthalic acid residues; optionally, aromatic dicarboxylic acid residues or aliphatic dicarboxylic acid residues or ester residues thereof; 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues; and 1,4-cyclohexanedimethanol residues.

Owner:EASTMAN CHEM CO

Polyester compositions containing cyclobutanediol and articles made therefrom

InactiveUS20060287479A1High glass transition temperatureHigh viscosityDialysis systemsDialysisFiberCarboxylic acid

Described are polyesters containing (a) a dicarboxylic acid component having from 70 to 100 mole % of terephthalic acid residues, and up to 30 mole % of aromatic dicarboxylic acid residues or aliphatic dicarboxylic acid residues; and (b) a glycol component having from 40 to 65 mole % of 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues, and from 35 to 60 mole % of 1,4-cyclohexanedimethanol residues; wherein the total mole % of the dicarboxylic acid component is 100 mole %, and the total mole % of the glycol component is 100 mole %. The polyesters may be manufactured into articles such as fibers, films, containers, bottles or sheets.

Owner:EASTMAN CHEM CO

Aliphatic polyester coating compositions containing tetramethyl cyclobutanediol

ActiveUS20100204401A1High glossHigh hardnessPolyurea/polyurethane coatingsPolyester coatingsSolvent freeSolvent based

Disclosed are aliphatic polyester resins containing 2,2,4,4-tetramethyl-1,3-cyclo-butanediol and solvent borne, thermosetting coating compositions prepared therefrom. The aliphatic polyesters exhibit good hardness and flexibility when formulated into thermosetting coatings compositions.

Owner:EASTMAN CHEM CO

Baby bottles comprising polyester compositions which comprise cyclobutanediol

ActiveUS20060286329A1Inherent glass transition temperatureInherent viscosityBottlesDialysis systemsCarboxylic acidDicarboxylic acid

Described are baby bottle(s) comprising polyesters comprising (a) a dicarboxylic acid component having terephthalic acid or an ester thereof; optionally, an aromatic dicarboxylic acid or aliphatic dicarboxylic acid or esters thereof; 2,2,4,4-tetramethyl-1,3-cyclobutanediol; and 1,4-cyclohexanedimethanol.

Owner:EASTMAN CHEM CO

Pacifiers comprising polyester compositions formed from 2,2,4,4- tetramethyl-1,3-cyclobutanediol and 1,4- cyclohexanedimethanol

InactiveUS20060287488A1Inherent glass transition temperatureInherent viscosityDialysis systemsDialysisCarboxylic acidDicarboxylic acid

Described are pacifiers comprising polyester compositions comprising polyesters which comprise (a) a dicarboxylic acid component having terephthalic acid residues; optionally, aromatic dicarboxylic acid residues or aliphatic dicarboxylic acid residues or ester residues thereof; 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues; and 1,4-cyclohexanedimethanol residues.

Owner:EASTMAN CHEM CO

Polyester compositions which comprise cyclobutanediol, cyclohexanedimethanol, and ethylene glycol and manufacturing processes therefor

Described as one aspect of the invention are polyester compositions comprising at least one polyester which comprises:(a) a dicarboxylic acid component comprising:(i) about 90 to about 100 mole % of terephthalic acid residues;(ii) about 0 to about 10 mole % of aromatic and / or aliphatic dicarboxylic acid residues having up to 20 carbon atoms; and(b) a glycol component comprising:(i) about 20 to about 40 mole % 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues; and(ii) about 20 to about 40 mole % cyclohexanedimethanol residues;(iii) ethylene glycol residues, and(iv) less than about 2 mole % of a modifying glycol having from 3 to 16 carbon atoms;wherein the total mole % of the dicarboxylic acid component is 100 mole %, andwherein the total mole % of the glycol component is 100 mole %; andwherein the inherent viscosity of the polyester is from 0.50 to 1.2 dL / g as determined in 60 / 40 (wt / wt) phenol / tetrachloroethane at a concentration of 0.25 g / 50 ml at 25° C. The polyesters may be manufactured into articles.

Owner:EASTMAN CHEM CO

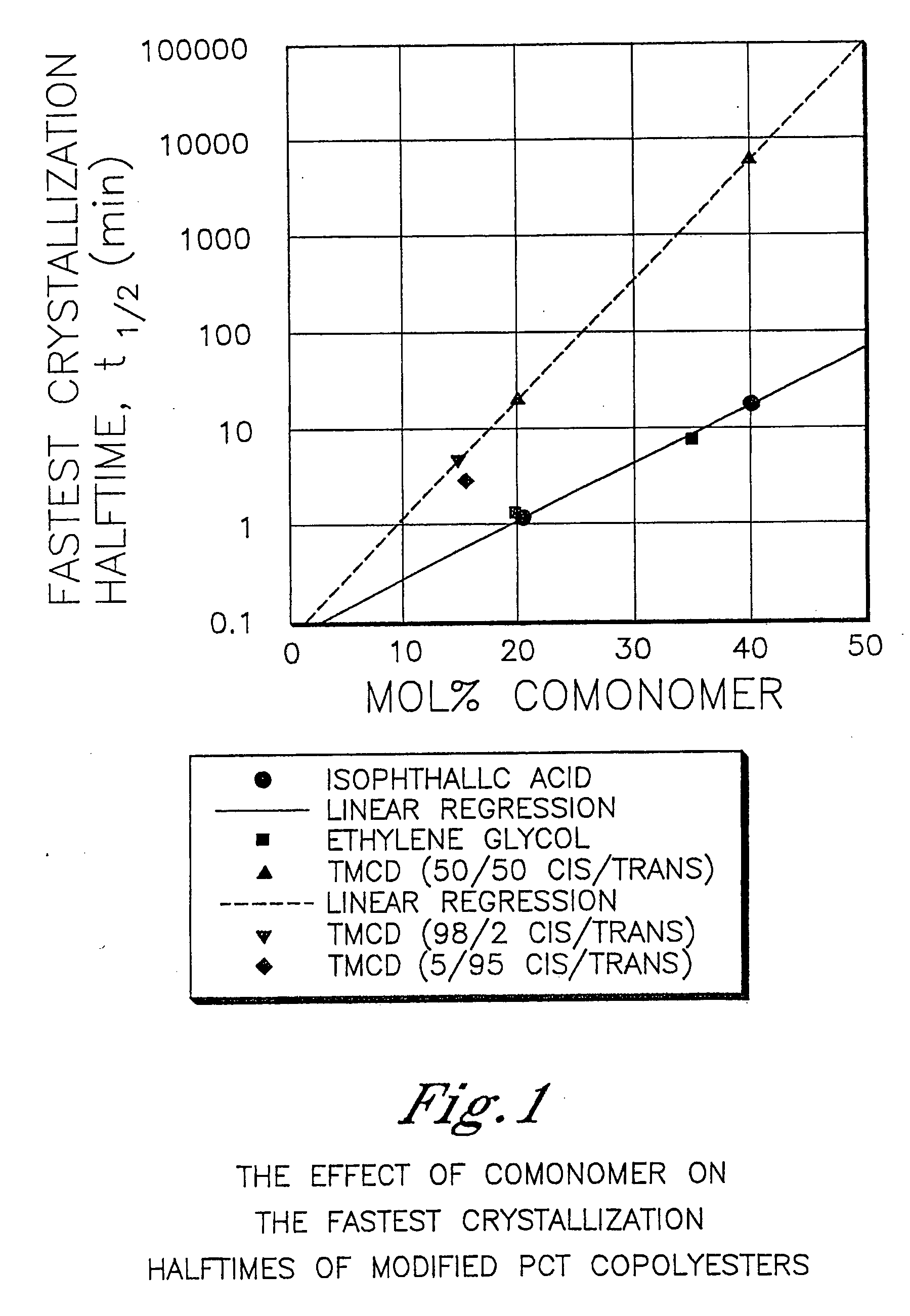

Clear Semi-Crystalline Articles with Improved Heat Resistance

InactiveUS20130217830A1Improve heat resistanceDown crystallization rateBottlesPackaging corrosive chemicalsFiberHeat resistance

The present invention relates to a clear, semicrystalline article comprising a polyester comprising terephthalic acid residues as the dicarboxylic acid component, and 1 to 15 mole % of 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues and 85 to 99 mole % of 1,4-cyclohexanedimethanol residues as the glycol component. The article may be in the form of a film or sheet, a bottle, or a fiber. The article, when produced by a process involving strain-induced crystallization, is characterized with high crystallinity.

Owner:EASTMAN CHEM CO

Polyester compositions containing low amounts of cyclobutanediol and articles made therefrom

InactiveUS20100096589A1Increase temperatureHigh viscosityLiquid crystal compositionsPlastic/resin/waxes insulatorsDicarboxylic acidCarboxylic acid

Described as one aspect of the invention are polyesters containing (a) a dicarboxylic acid component having from 70 to 100 mole % of terephthalic acid residues and up to 30 mole % of aromatic dicarboxylic acid residues or aliphatic dicarboxylic acid residues; and (b) a glycol component having from 11 to 25 mole % of 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues, and 75 to 89 mole % of cyclohexanedimethanol residues; wherein the total mole % of the dicarboxylic acid component is 100 mole %, and the total mole % of the glycol component is 100 mole %. The polyesters may be manufactured into articles.

Owner:EASTMAN CHEM CO

Aliphatic polyester coating compositions containing tetramethyl cyclobutanediol

InactiveUS20140296407A1High glossHigh hardnessPolyurea/polyurethane coatingsPolyester coatingsPolyester resinSolvent

Owner:EASTMAN CHEM CO

Unsaturated polyester resin compositions containing 2,2,2,4-tetramethyl-1,3-cyclobutanediol and articles made therefrom

Disclosed are unsaturated polyester resins comprising residues of 1,2-propanediol, 2,2,4,4-tetramethyl-1,3-cyclobutanediol, an aliphatic, cycloaliphatic, or aromatic diacid, and 2-butenedioic acid. Also disclosed are curable compositions containing admixtures of the unsaturated polyesters and aromatic vinyl compounds copolymerizable with the unsaturated polyesters, and coatings and casted and molded articles obtained from the curable compositions. The curable compositions are useful for coatings and casted and molded articles that have at least one surface that is persistently exposed to organic or aqueous liquids.

Owner:EASTMAN CHEM CO

Polyester compositions containing low amounts of cyclobutanediol and articles made therefrom

ActiveUS20060287481A1High glass transition temperatureHigh viscosityDialysis systemsDialysisDicarboxylic acidCarboxylic acid

Described as one aspect of the invention are polyesters containing (a) a dicarboxylic acid component having from 70 to 100 mole % of terephthalic acid residues and up to 30 mole % of aromatic dicarboxylic acid residues or aliphatic dicarboxylic acid residues; and (b) a glycol component having from 11 to 25 mole % of 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues, and 75 to 89 mole % of 1,4-cyclohexanedimethanol residues; wherein the total mole % of the dicarboxylic acid component is 100 mole %, and the total mole % of the glycol component is 100 mole %. The polyesters may be manufactured into articles.

Owner:EASTMAN CHEM CO

Thermoplastic articles comprising cyclobutanediol having a decorative material embedded therein

This invention relates to thermoplastic article having one or more decorative materials embedded therein which is obtained by applying heat and pressure to one or more laminates wherein at least one of said laminates comprises, in order, (1) an upper sheet material; (2) one or more decorative materials; and (3) a lower sheet material; wherein the upper and lower sheet materials are formed from a polyester / aromatic polycarbonate blend wherein the thermoplastic article comprises at least one polyester composition comprising at least one polyester which comprises terephthalic acid and 2,2,4,4-tetramethyl-1,3-cyclobutanediol.

Owner:EASTMAN CHEM CO

Transparent polymer blends containing polyesters comprising a cyclobutanediol and articles prepared therefrom

ActiveUS7955674B2Easy to processImprove propertiesEnvelopes/bags making machineryBottlesPolyesterPolymer science

Disclosed are polymer compositions having high transparency and low haze comprising immiscible blends of at least one polyester comprising 2,2,4,4-tetramethyl-1,3-cyclobutanediol, and a copolyamide or a transamidized, homogeneous blend of a least two polyamides. The components of the immiscible blend have refractive indices which differ by about 0.006 to about −0.0006. The small difference in the refractive indices enable the incorporation of regrind into the polymer composition to produce transparent shaped articles. The blends of the present invention are useful in producing shaped articles such as, for example, sheeting, films, tubes, bottles, preforms and profiles. These articles may have one or more layers and can exhibit improved excellent barrier properties and good melt processability while retaining excellent mechanical properties. Metal catalysts can be incorporated into the compositions to produce oxygen-scavenging compositions.

Owner:EASTMAN CHEM CO

LCD films comprising polyester compositions formed from 2,2,4,4-tetramethyl-1,3-cyclobutanediol and 1,4-cyclohexanedimethanol

InactiveUS20070010649A1Inherent temperatureInherent viscosityDialysis systemsDialysisDicarboxylic acidCarboxylic acid

Described are LCD films or sheets comprising polyester compositions comprising polyesters which comprise (a) a dicarboxylic acid component having terephthalic acid residues; optionally, aromatic dicarboxylic acid residues or aliphatic dicarboxylic acid residues or ester residues thereof; 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues; and 1,4-cyclohexanedimethanol residues.

Owner:EASTMAN CHEM CO

Retort containers comprising polyester compositions formed from 2,2,4,4-tetramethyl-1,3-cyclobutanediol and 1,4-cyclohexanedimethanol

InactiveUS20060286327A1Inherent glass transition temperatureInherent viscosityBottlesDialysis systemsDicarboxylic acidCarboxylic acid

Described are retort food containers comprising polyester compositions comprising polyesters which comprise (a) a dicarboxylic acid component having terephthalic acid residues; optionally, aromatic dicarboxylic acid residues or aliphatic dicarboxylic acid residues or ester residues thereof; 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues; and 1,4-cyclohexanedimethanol residues.

Owner:CRAWFORD EMMETT DUDLEY +4

Skylights and windows comprising polyester compositions formed from 2,2,4,4,-tetramethyl-1,3-cyclobutanediol and 1,4-cyclohexanedimethanol

InactiveUS20060287483A1Inherent glass transition temperatureInherent viscosityDialysis systemsDialysisCarboxylic acidDicarboxylic acid

Described are skylights comprising polyester compositions comprising polyesters which comprise (a) a dicarboxylic acid component having terephthalic acid residues; optionally, aromatic dicarboxylic acid residues or aliphatic dicarboxylic acid residues or ester residues thereof; 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues; and 1,4-cyclohexanedimethanol residues.

Owner:EASTMAN CHEM CO

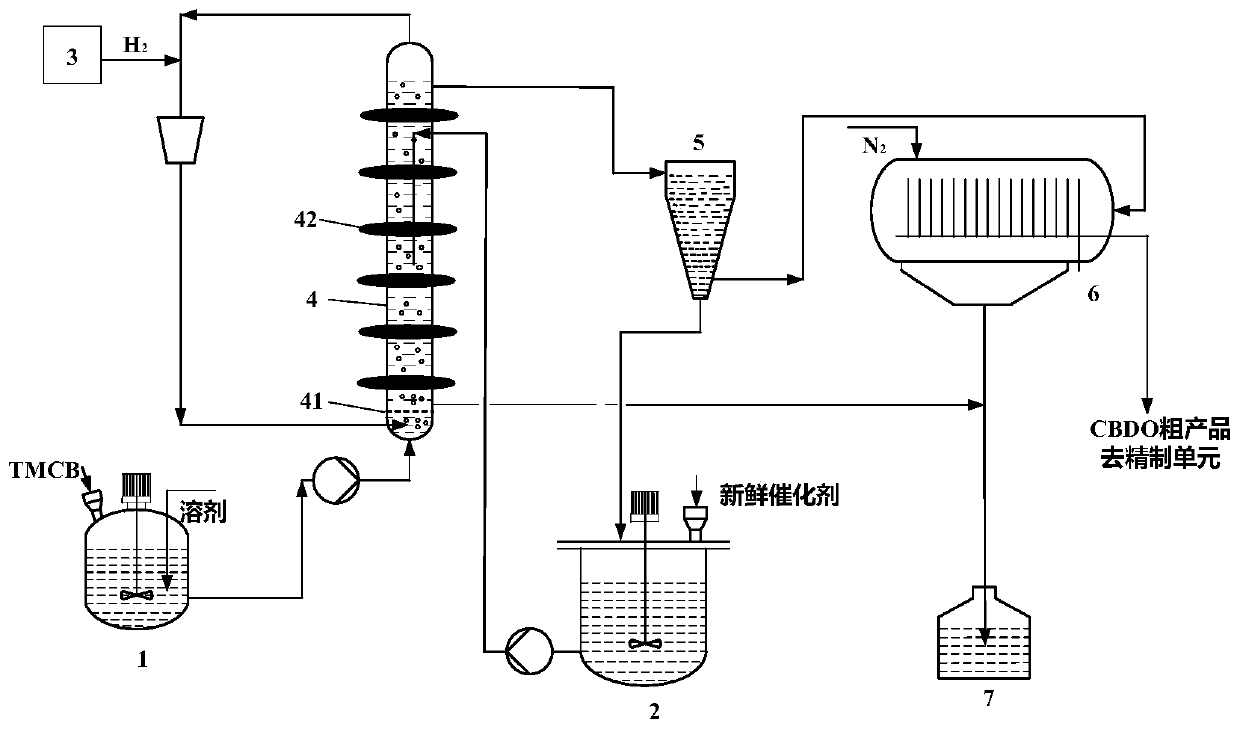

Catalyst, preparation method thereof, and apparatus and method for preparing 2,2,4,4-tetramethyl-1,3-cyclobutanediol

InactiveCN110124674AImprove conversion rateHigh yieldOrganic compound preparationHydroxy compound preparationKetoneMethyl group

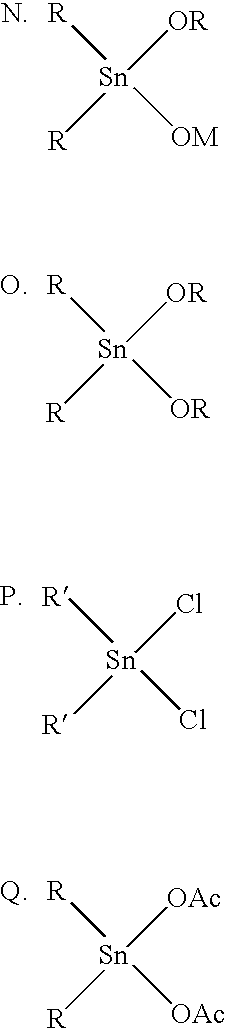

The invention relates to the field of production of 2,2,4,4-tetramethyl-1,3-cyclobutanediol, and concretely relates to a catalyst, a preparation method thereof, and an apparatus and a method for preparing 2,2,4,4-tetramethyl-1,3-clobutanediol. The catalyst comprises a main active metal element, a metalloid element, a carrier and an optional coactive metal element, the main active metal element isone or more of Fe, Co and Ni, the metalloid element is B and / or P, and the coactive active metal element is one or more of Co, Ru, Pd, Rh, Ir, and Pt; and the content of the main active metal elementin the catalyst is 1-70 wt%. The catalyst, the apparatus and the preparation methods of the invention are used to realize high-efficiency conversion of ketones, improve the cis-trans isomer molar ratio of the 2,2,4,4-tetramethyl-1,3-cyclobutanediol product and reduce the wearing and consumption of the catalyst.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

Preparation of transparent, multilayered articles containing polyesters comprising a cyclobutanediol and homogeneous polyamide blends

ActiveUS7462684B2Easy to processImprove propertiesBottlesSynthetic resin layered productsPolyesterPolymer science

Disclosed is a process for the preparation of multilayered, shaped articles having high transparency and low haze and in which at least one layer contains at least one polyester comprising 2,2,4,4-tetramethyl-1,3-cyclobutanediol and a separate layer which contains a transamidized, homogeneous blend of a least two polyamides. The polyester component and the polyamide component have refractive indices which differ by about 0.006 to about −0.0006. The small difference in the refractive indices enable the incorporation of regrind into one or more of the layers of the article while maintaining high clarity. These articles can exhibit improved excellent barrier properties and good melt processability while retaining excellent mechanical properties. Metal catalysts can be incorporated into one or more layers to impart oxygen-scavenging properties.

Owner:EASTMAN CHEM CO

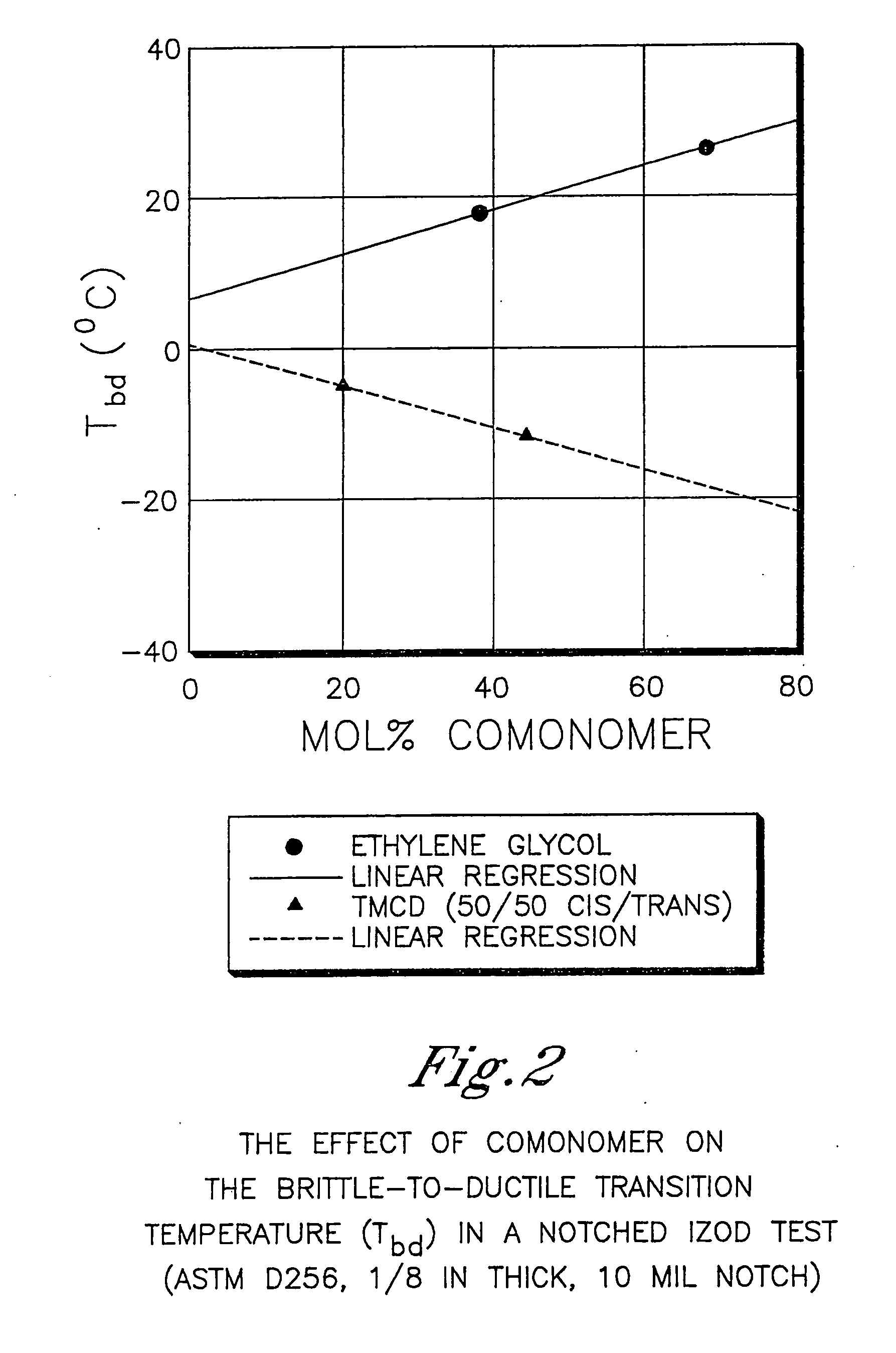

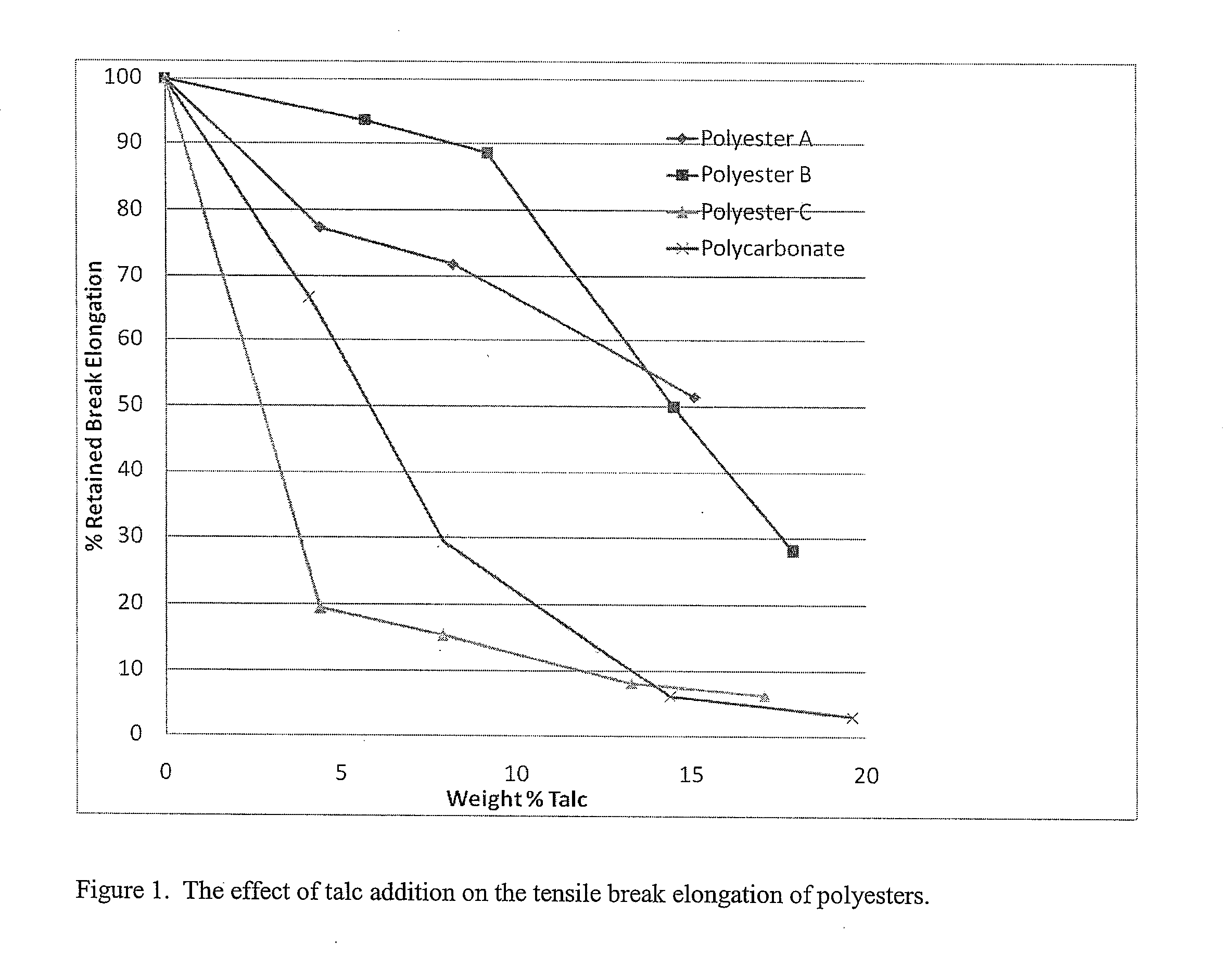

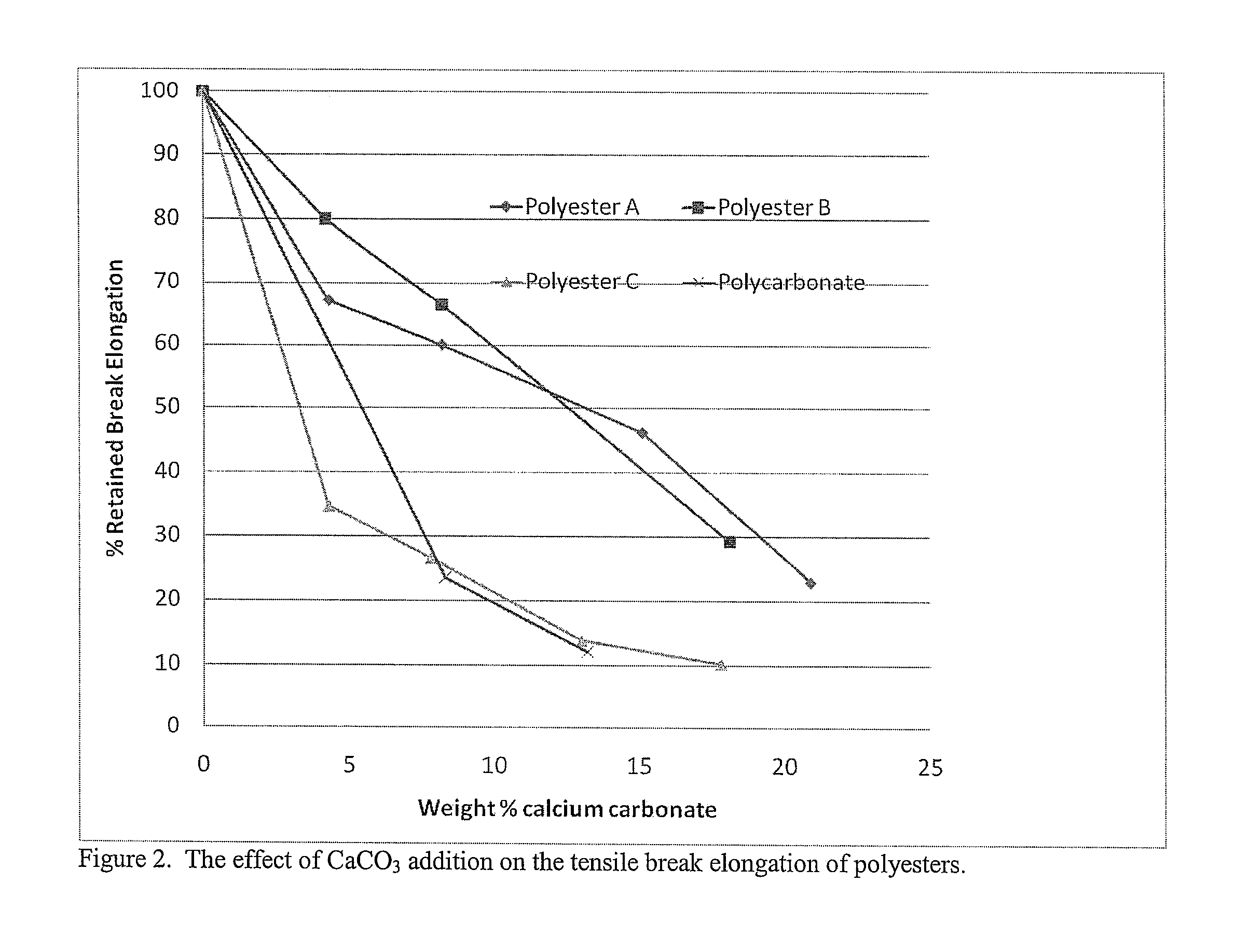

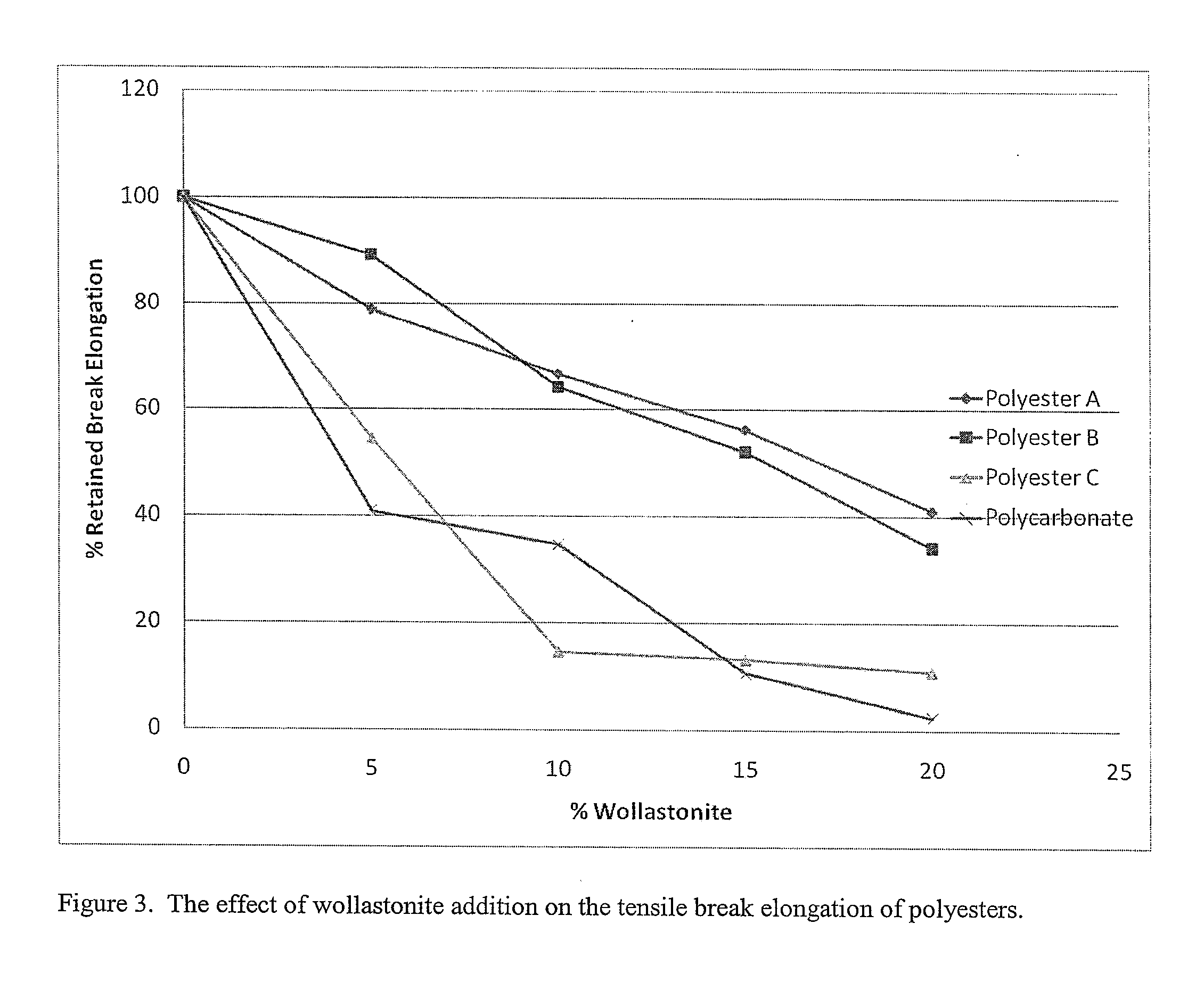

Reinforced polyester compositions having improved toughness

Polymer compositions are disclosed that are blends of polyesters prepared from terephthalic acid, 2,2,4,4-tetramethyl-1,3-cyclobutanediol, and optionally 1,4-cyclohexanedimethanol, with a reinforcing mineral filler. The composition of the blend includes up to about 40 weight % of the mineral. These formulations have a combination of toughness, heat resistance, and high modulus making the materials particularly useful in engineering molding plastics.

Owner:EASTMAN CHEM CO

Outdoor signs comprising polyester compositions formed from 2,2,4,4-tetramethyl-1,3-cyclobutanediol and 1,4-cyclohexanedimethanol

ActiveUS20060287490A1Inherent glass transition temperatureInherent viscosityDialysis systemsDialysisDicarboxylic acidCarboxylic acid

Described are outdoor signs comprising polyester compositions comprising polyesters which comprise (a) a dicarboxylic acid component having terephthalic acid residues; optionally, aromatic dicarboxylic acid residues or aliphatic dicarboxylic acid residues or ester residues thereof; 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues; and 1,4-cyclohexanedimethanol residues.

Owner:EASTMAN CHEM CO

Sterilization containers comprising polyester compositions formed from 2,2,4,4-tetramethyl-1,3-cyclobutanediol and 1,4-cyclohexanedimethanol

InactiveUS20060286330A1Inherent glass transition temperatureInherent viscosityBottlesDialysis systemsDicarboxylic acid2,2,4,4-Tetramethyl-1,3-cyclobutanediol

Described are infant-care sterilization containers comprising polyester compositions comprising polyesters which comprise (a) a dicarboxylicacidcomponent having terephthalic acid residues; optionally, aromatic dicarboxylic acid residues or aliphatic dicarboxylic acid residues or ester residues thereof; 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues; and 1,4-cyclohexanedimethanol residues.

Owner:EASTMAN CHEM CO

Intravenous components comprising polyester compositions formed from 2,2,4,4-tetramethyl-1,3-cyclobutanediol and 1,4-cyclohexanedimethanol

ActiveUS20060287495A1Inherent temperatureInherent viscosityDialysis systemsDialysisDicarboxylic acidCarboxylic acid

Described are intravenous components comprising polyester compositions comprising polyesters which comprise (a) a dicarboxylic acid component having terephthalic acid residues; optionally, aromatic dicarboxylic acid residues or aliphatic dicarboxylic acid residues or ester residues thereof; 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues; and 1,4-cyclohexanedimethanol residues.

Owner:EASTMAN CHEM CO

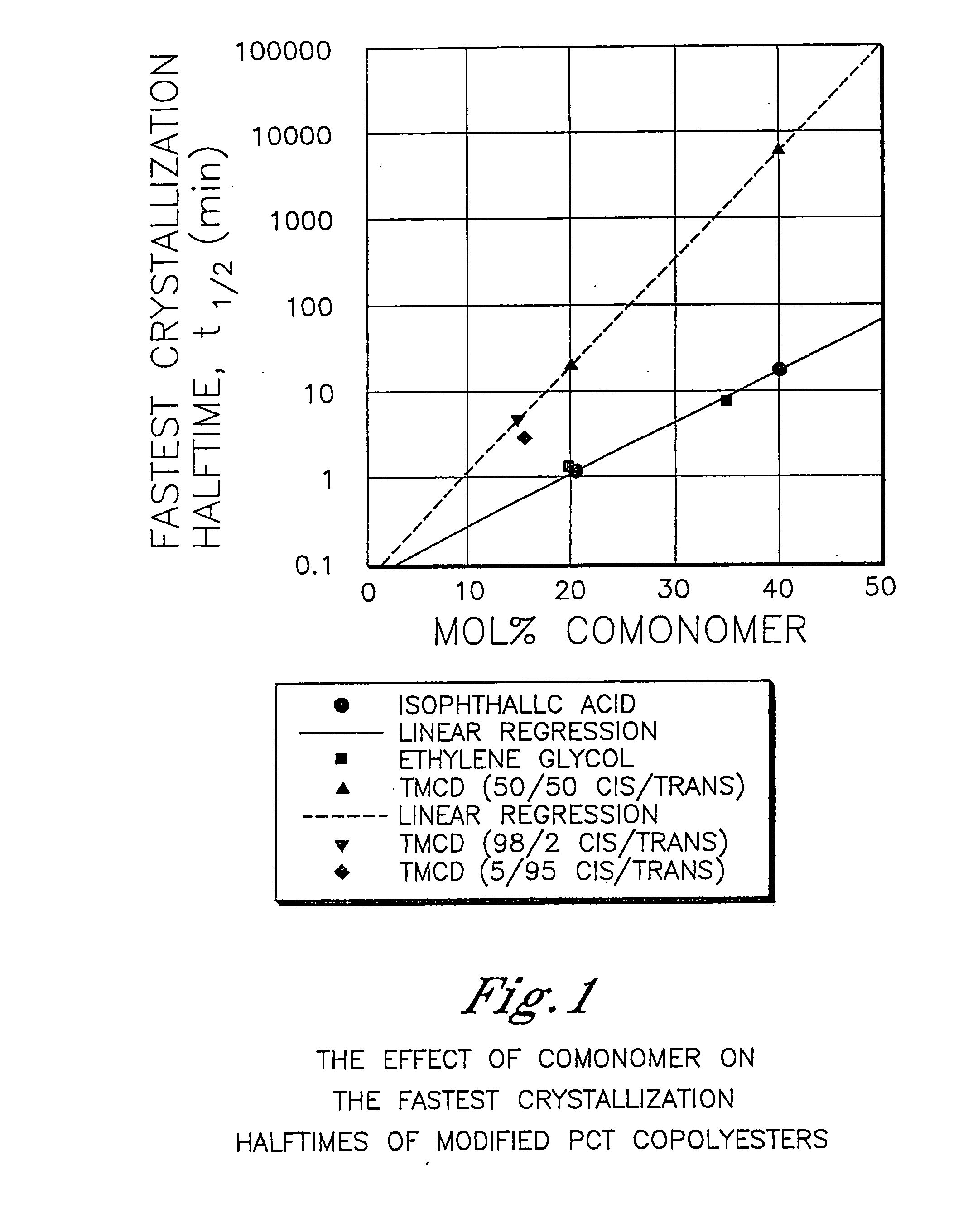

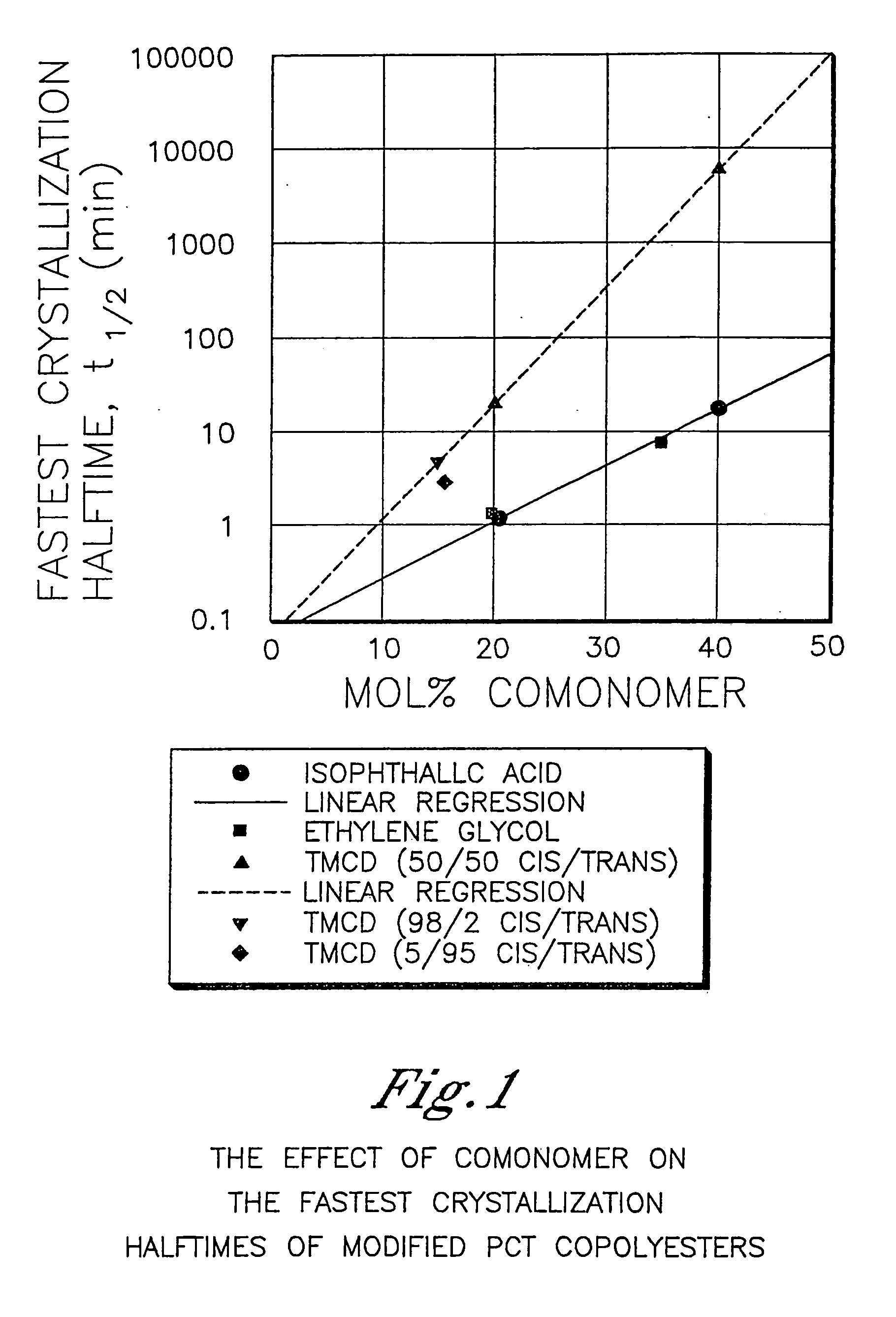

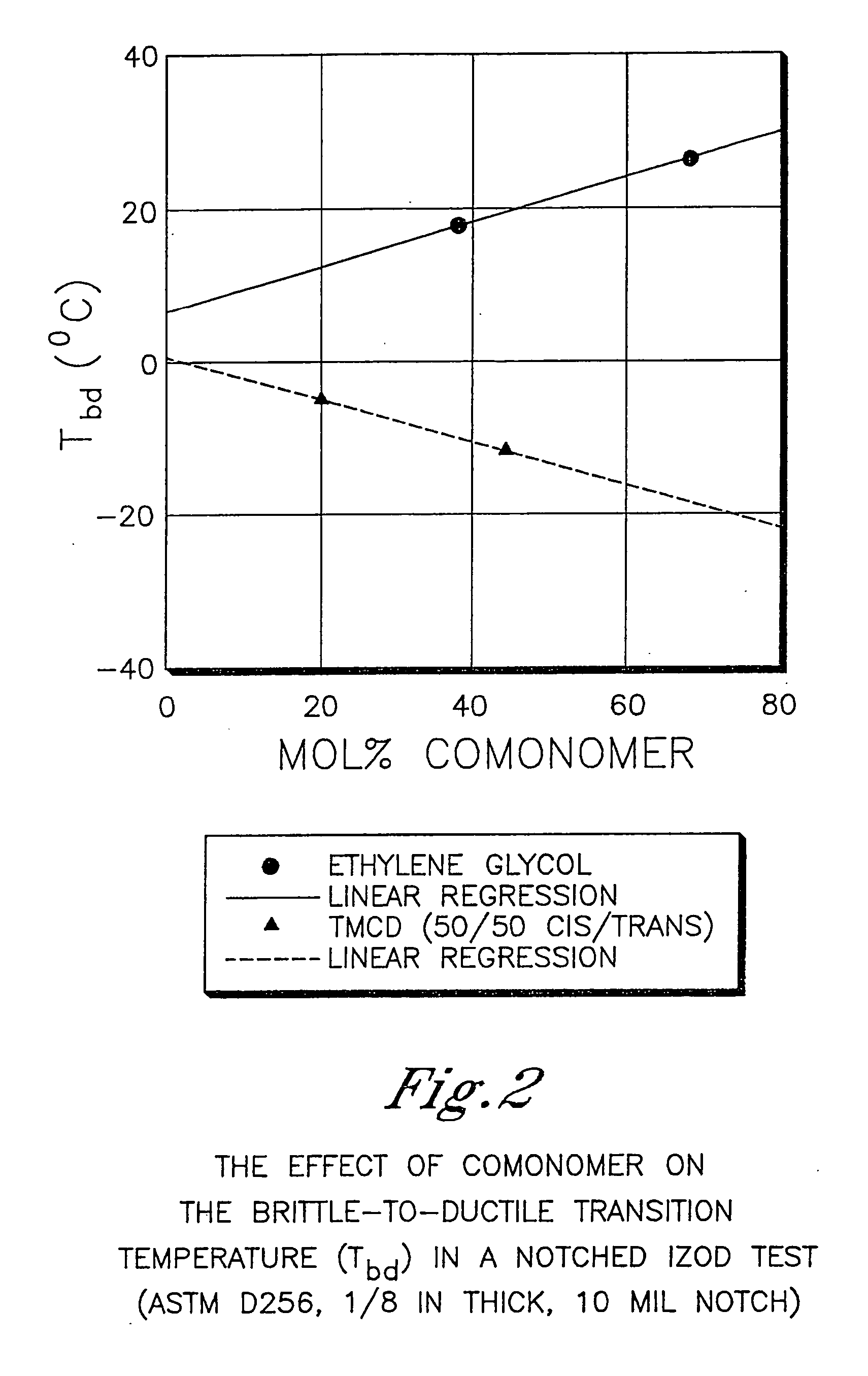

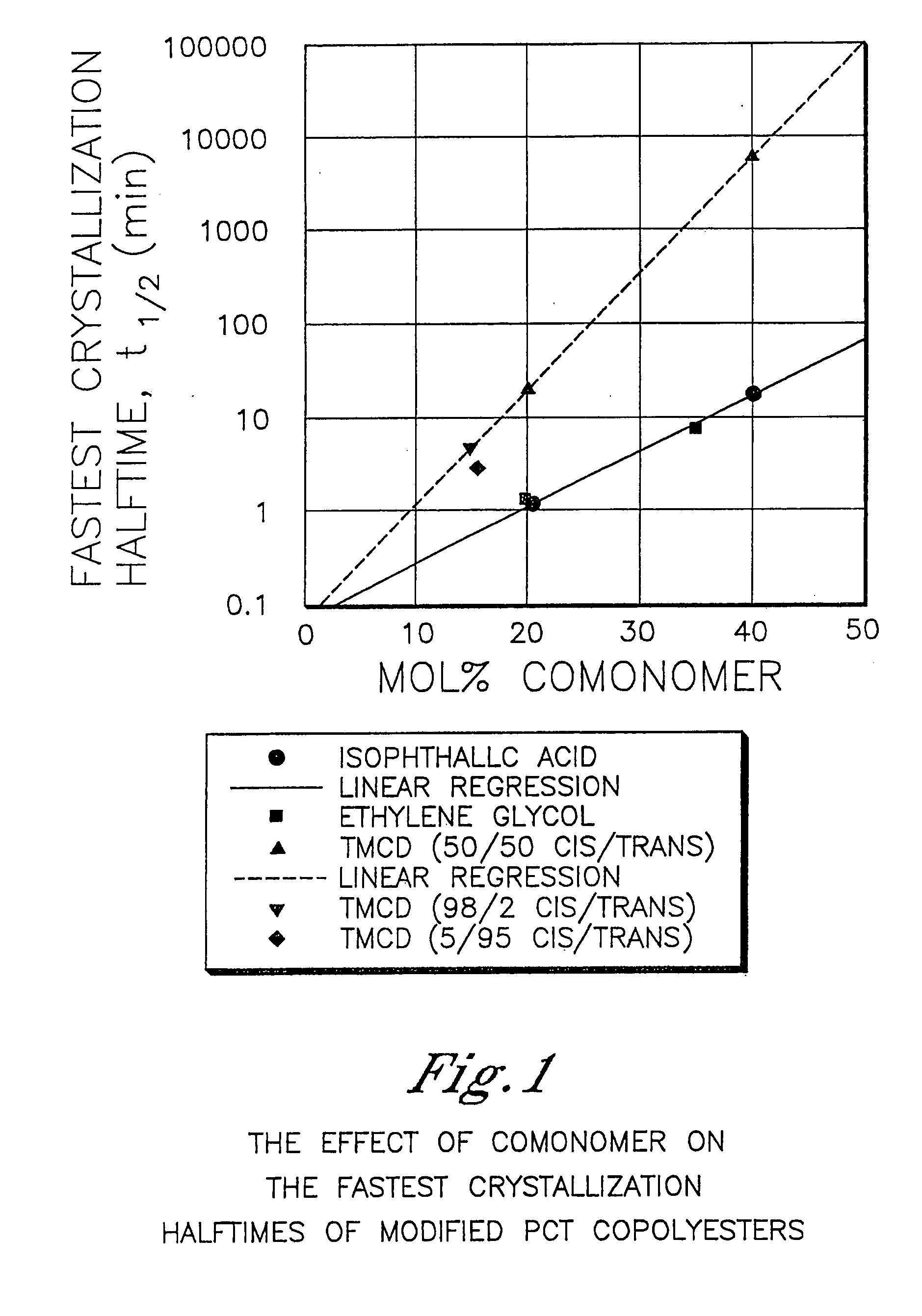

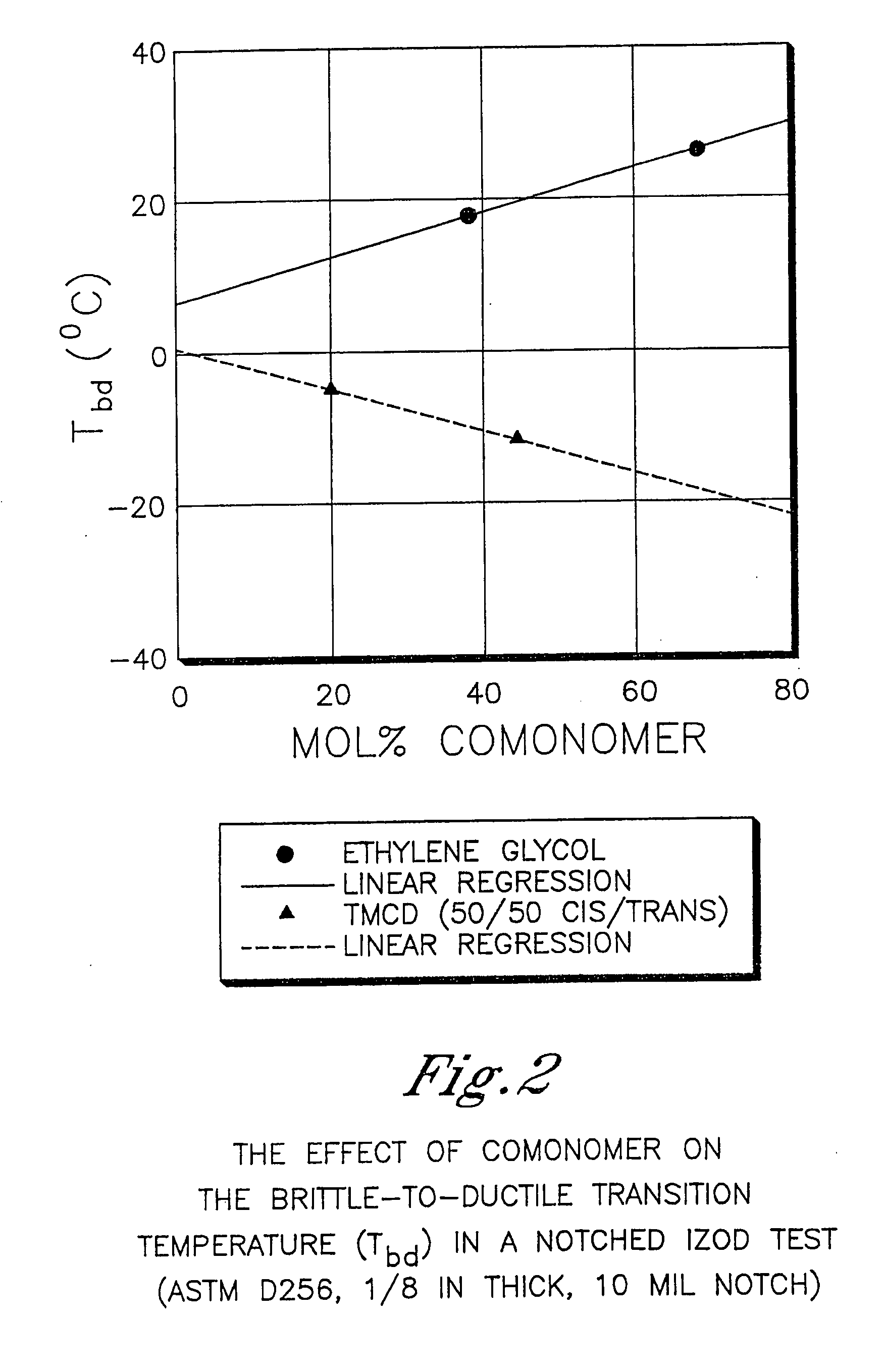

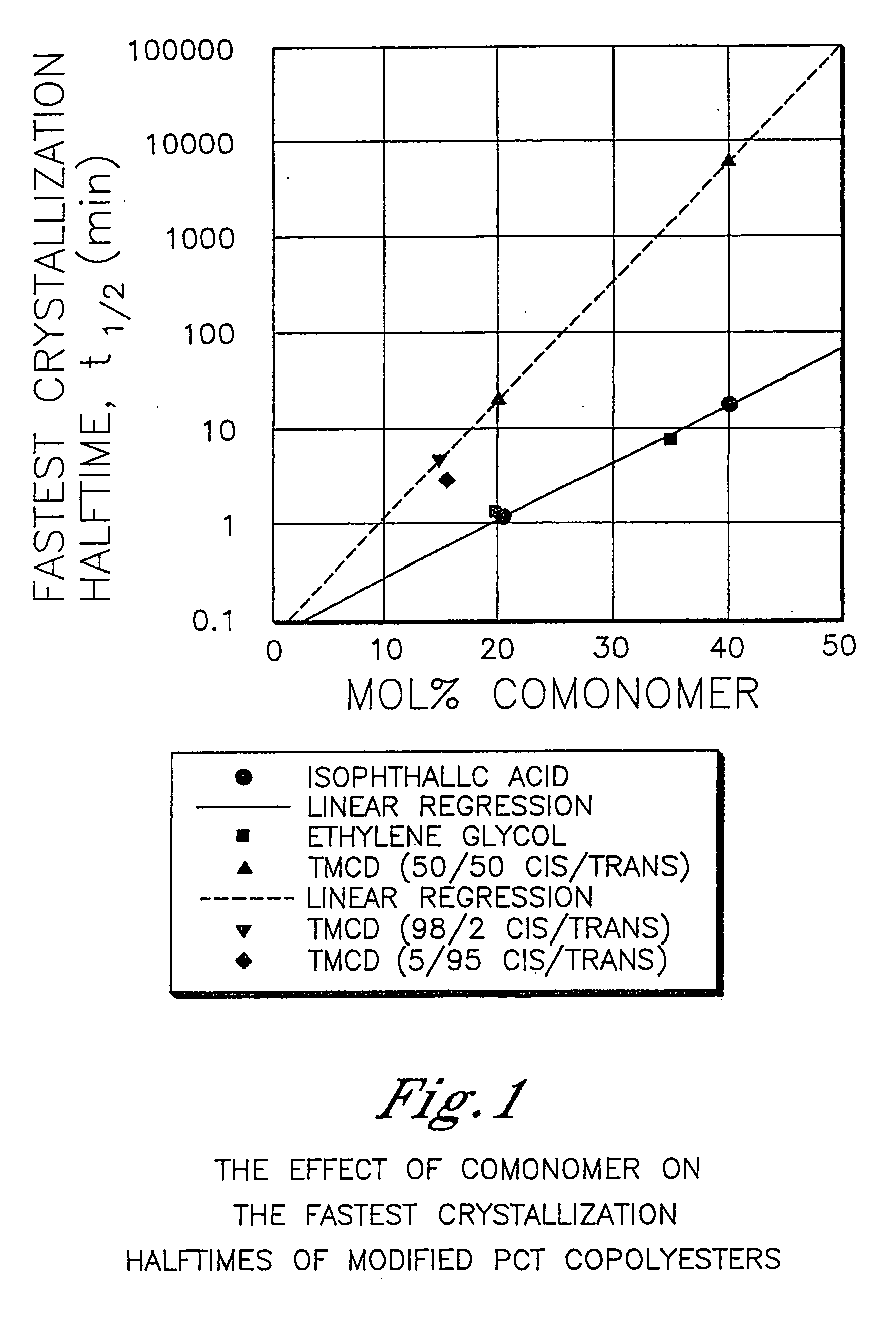

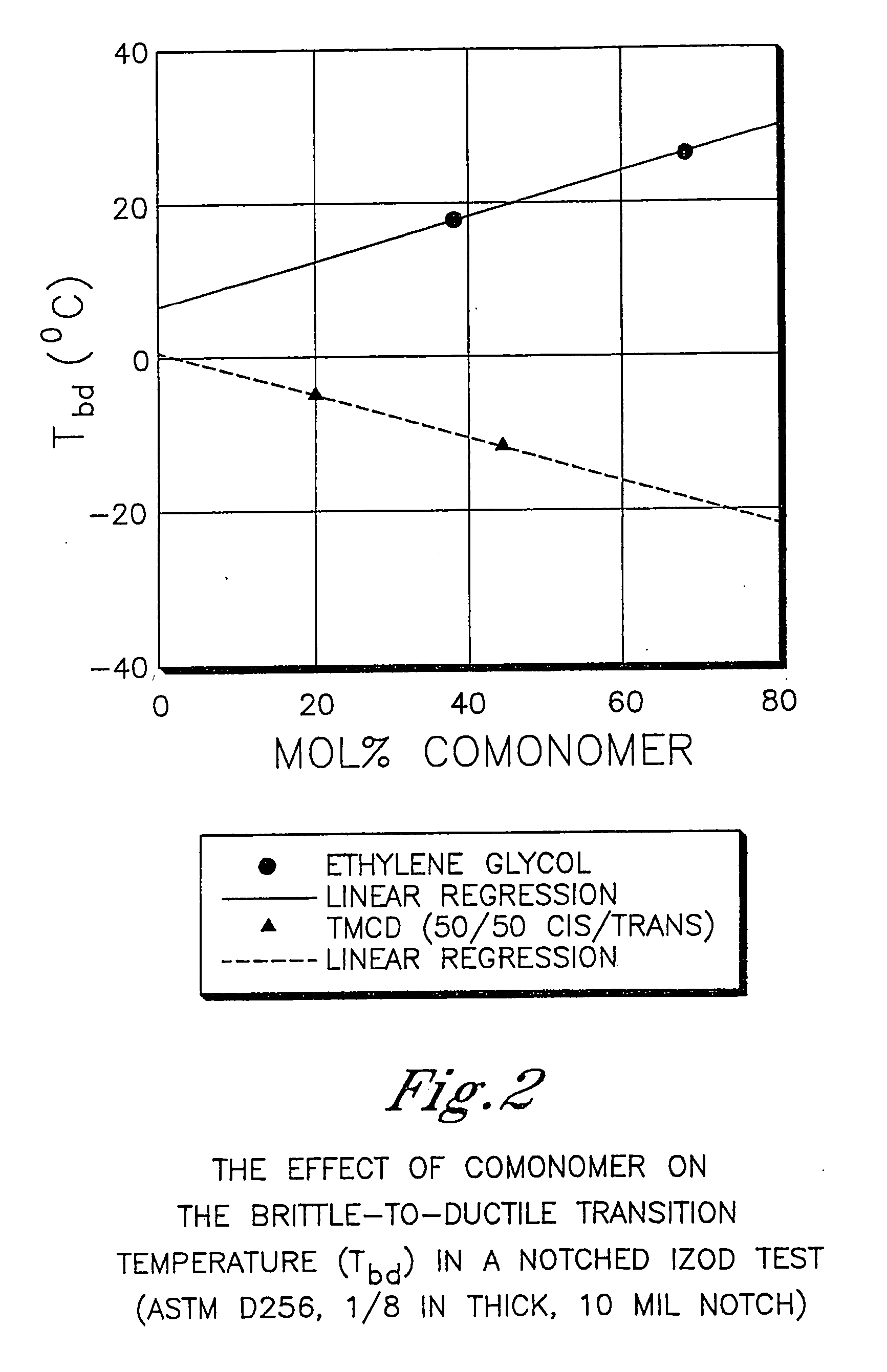

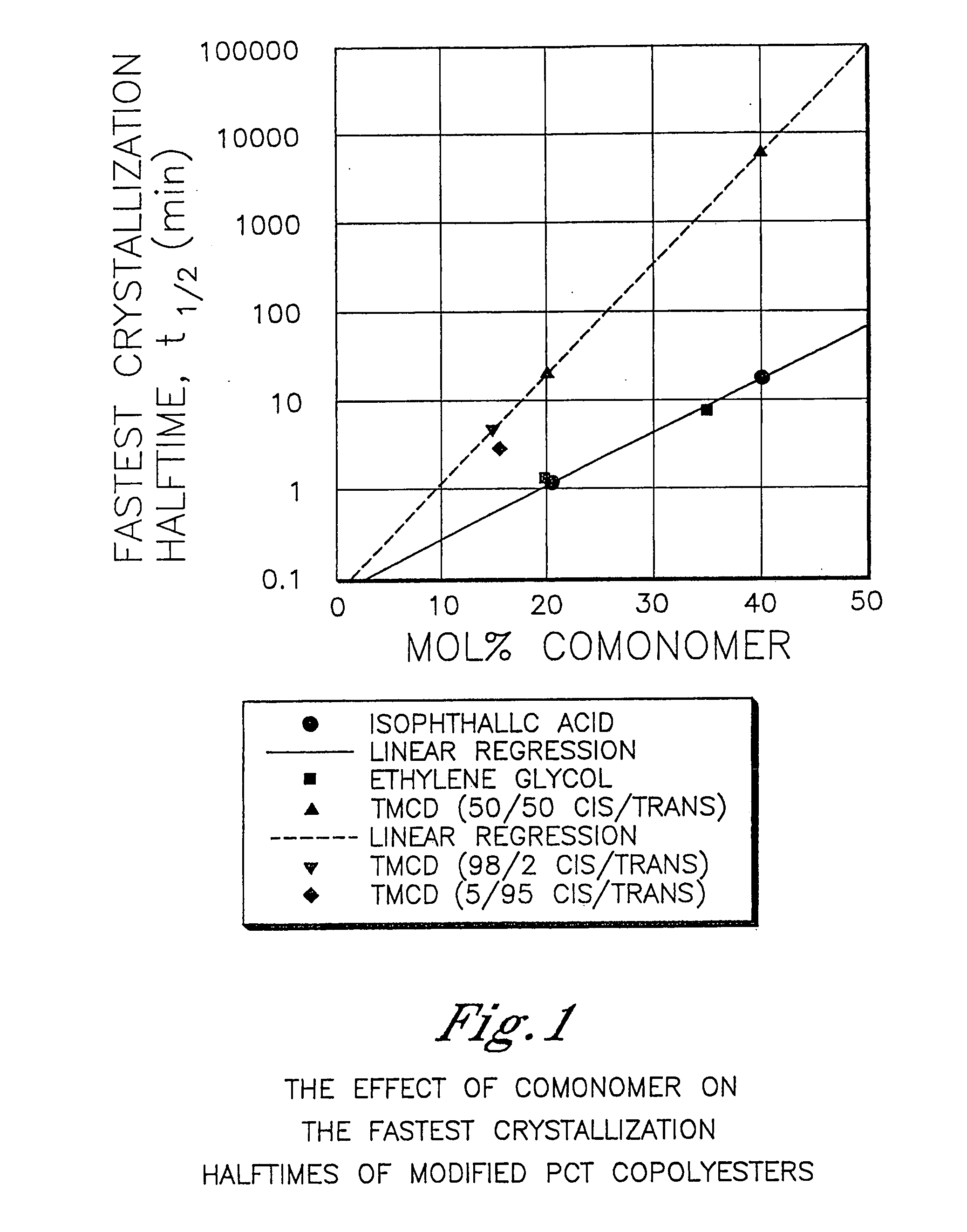

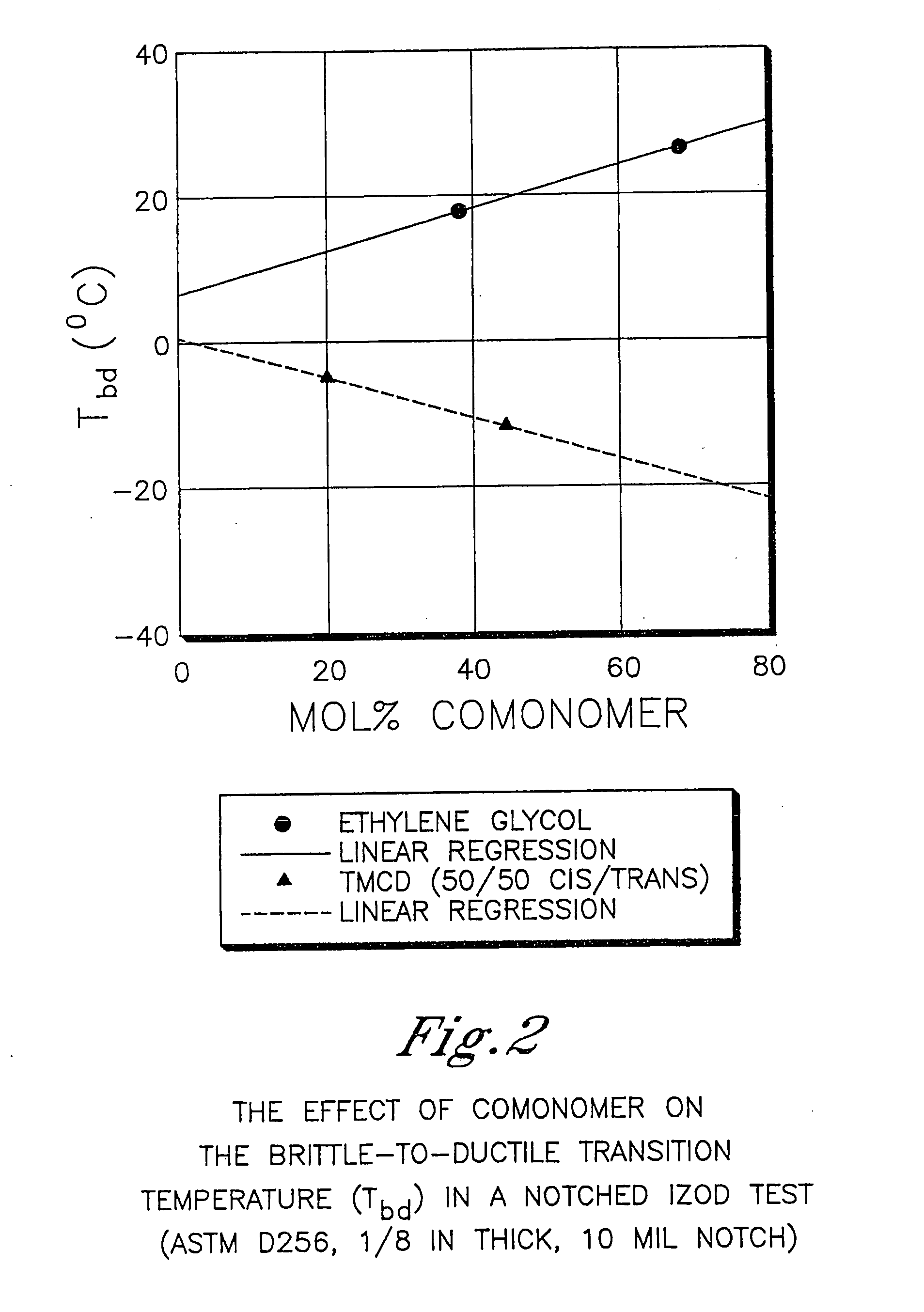

Polyester compositions which comprise cyclobutanediol having certain cis/trans ratios

ActiveUS20060287489A1Good chemical resistanceHigh strength stabilityDialysis systemsDialysisCarboxylic acidDicarboxylic acid

Described are polyester compositions comprising (a) a dicarboxylic acid component comprising terephthalic acid residues; optionally, aromatic dicarboxylic acid or aliphatic dicarboxylic acid residues; 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues, wherein said 2,2,4,4-tetramethyl-1,3-cyclobutanediol contains certain cis to trans ratios; and 1,4-cyclohexanedimethanol residues.

Owner:EASTMAN CHEM CO

Sound barriers comprising polyester compositions formed from 2,2,4,4-tetramethyl-1,3-cyclobutanediol and 1,4-cyclohexanedimethanol

InactiveUS20060287485A1Inherent glass transition temperatureInherent viscosityDialysis systemsDialysisCarboxylic acidDicarboxylic acid

Described are sound barriers comprising polyester compositions comprising polyesters which comprise (a) a dicarboxylic acid component having terephthalic acid residues; optionally, aromatic dicarboxylic acid residues or aliphatic dicarboxylic acid residues or ester residues thereof; 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues; and 1,4-cyclohexanedimethanol residues.

Owner:EASTMAN CHEM CO

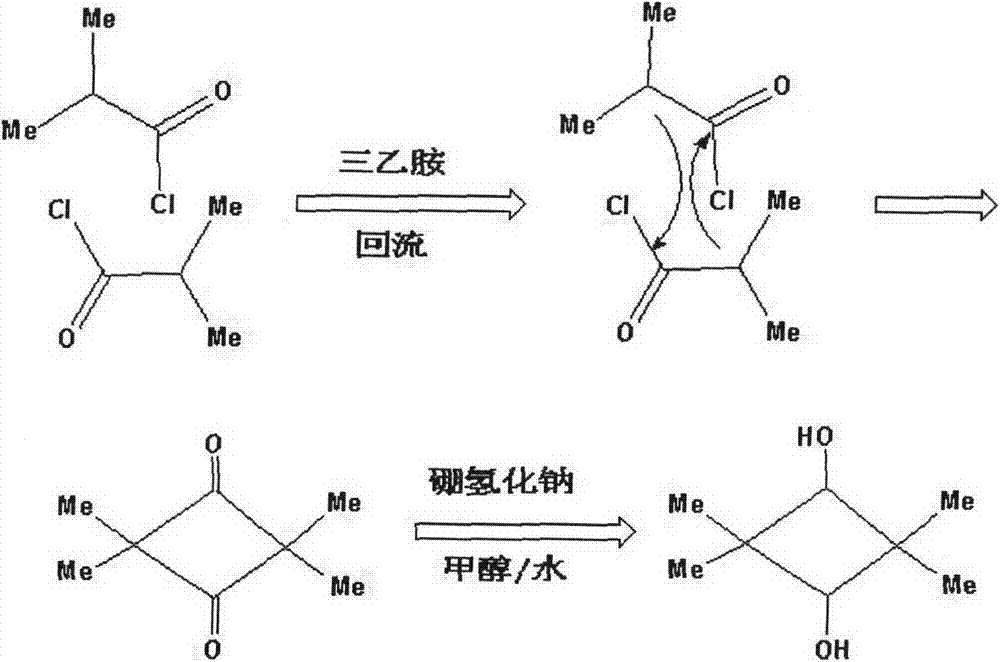

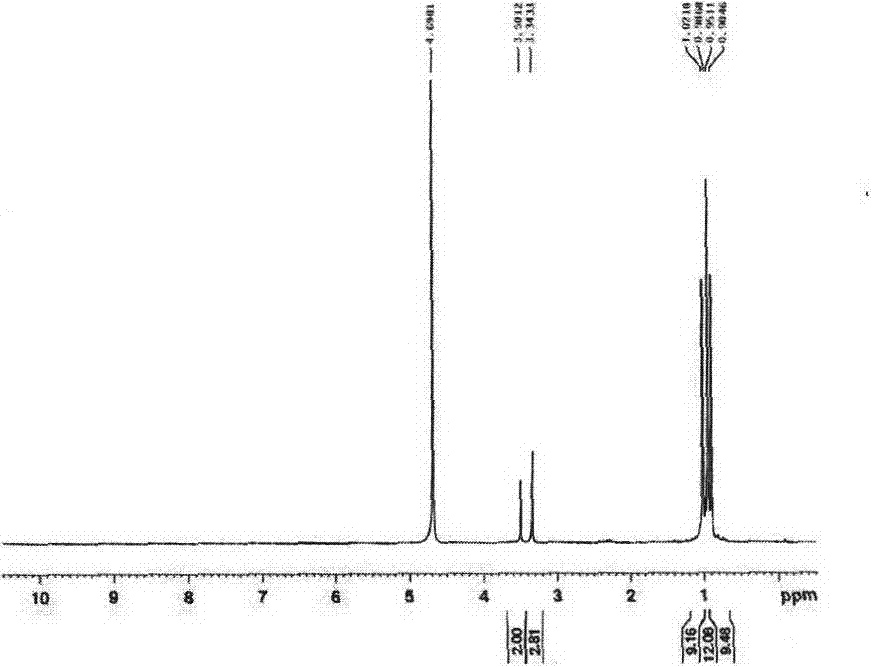

Method for synthesizing 2,2,4,4-tetramethyl-1,3-cyclobutanediol

InactiveCN103694083ALow costMild operating conditionsOrganic compound preparationHydroxy compound preparationEvaporationMethyl group

The invention discloses a method for preparing 2,2,4,4-tetramethyl-1,3-cyclobutanediol. Iso-butyryl chloride used as a raw material is stirred evenly in ether solvent, triethylamine is added, reflux reaction is carried out for 13-16h, diluted hydrochloric acid is used for washing, pressure is reduced to remove solvent to obtain intermediate 2,2,4,4-tetramethyl-1,3-cyclobutanedione, the intermediate is dissolved in mixed solvent of methyl alcohol and water, NaOH is used for regulating pH value to be alkaline, quantitative NaBH4 is added in batches under an ice-bath condition, the reaction is performed for 3-5h at normal temperature, diluted hydrochloric acid is used for quenching, solvent is removed, absolute ethyl alcohol is used for extraction, after ethyl alcohol is removed through rotary evaporation, water is used for extraction, and finally, the water is removed to obtain 2,2,4,4-tetramethyl-1,3-cyclobutanediol. The method has simple equipment requirement, mild operation condition, low cost and high product purity, and is suitable for industrial production.

Owner:NANJING NANOEAST BIOTECH +1

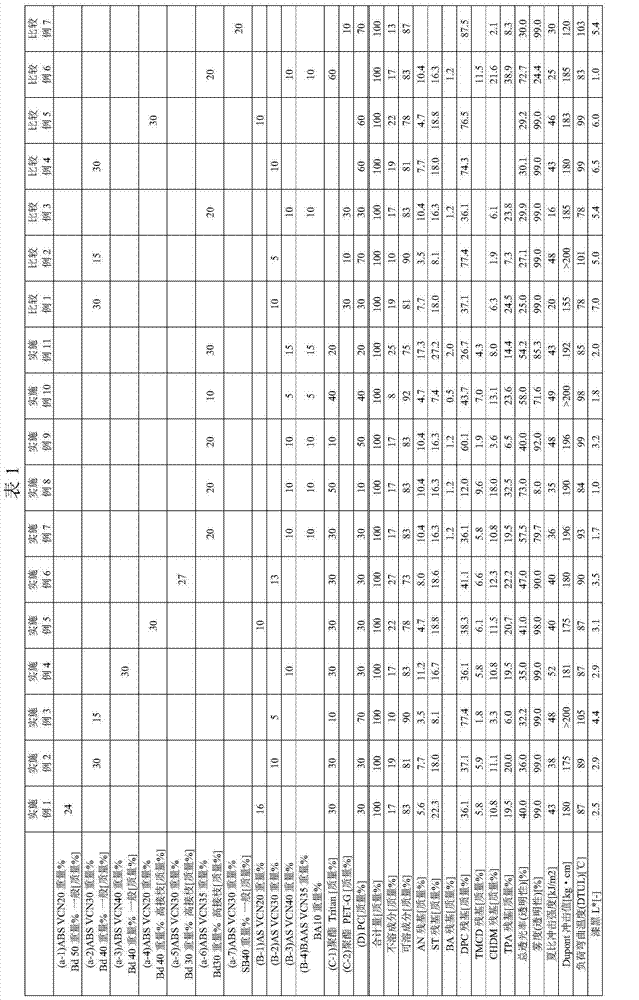

Thermoplastic resin composition and molded product thereof

A thermoplastic resin composition comprising (A) a graft copolymer produced by grafting at least one monomer selected from the group consisting of an aromatic vinyl monomer, a vinyl cyanide monomer and other copolymerizable monomers onto a rubbery polymer, (B) a polymer produced by polymerizing at least one monomer selected from the group consisting of an aromatic vinyl monomer, a vinyl cyanide monomer and other copolymerizable monomers, (C) an amorphous polyester and (D) an aromatic polycarbonate, wherein the component (C) contains diol components, and wherein a 2,2,4,4-tetramethyl-1,3-cyclobutanediol (TMCD) residue and a 1,4-cyclohexanedimethanol (CHDM) residue are contained in amounts of 10 to 70 mol% and 30 to 90 mol%, respectively, relative to the total molar percentage, i.e., 100 mol%, of the diol components.

Owner:NIPPON A & L INC

Appliance parts comprising polyester compositions formed from 2,2,4,4-tetramethyl-1,3-cyclobutanediol and 1,4-cyclohexanedimethanol

ActiveUS20060287491A1Inherent glass transition temperatureInherent viscosityDialysis systemsDialysisDicarboxylic acidCarboxylic acid

Described are appliance parts comprising polyester compositions comprising polyesters which comprise (a) a dicarboxylic acid component having terephthalic acid residues; optionally, aromatic dicarboxylic acid residues or aliphatic dicarboxylic acid residues or ester residues thereof; 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues; and 1,4-cyclohexanedimethanol residues.

Owner:EASTMAN CHEM CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com