Bi2O3/BiFeO3/TiO2 nano-flower photocatalytic material and preparation method thereof

A catalytic material, nanoflower technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve high feasibility, improve visible light utilization, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

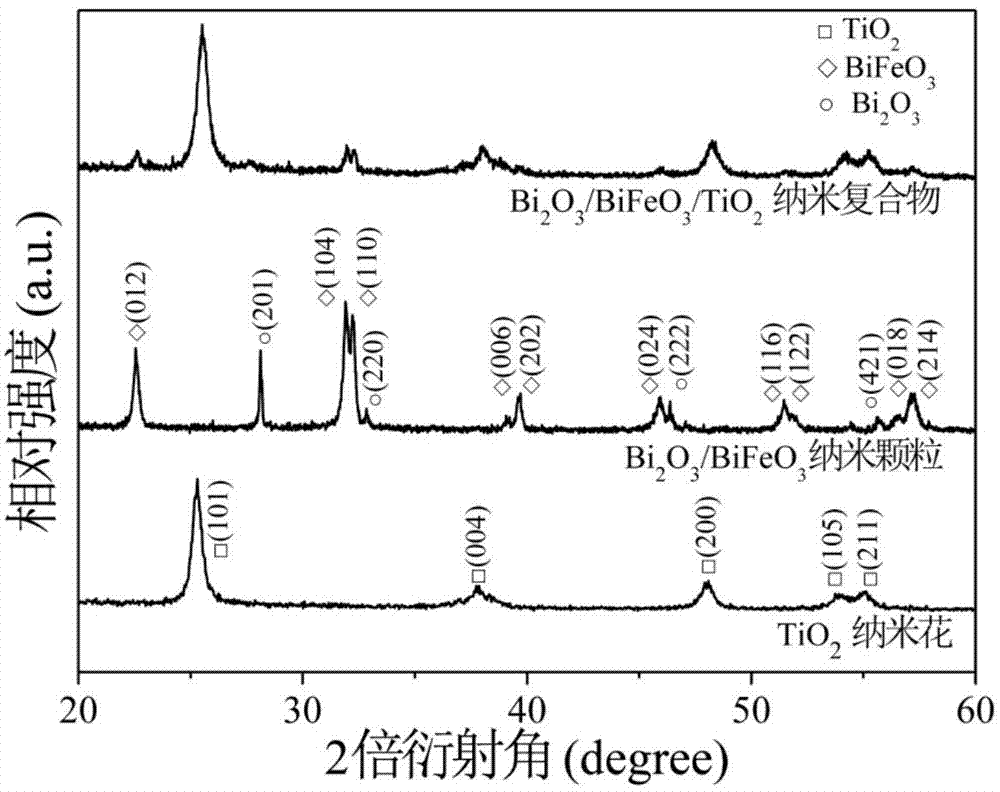

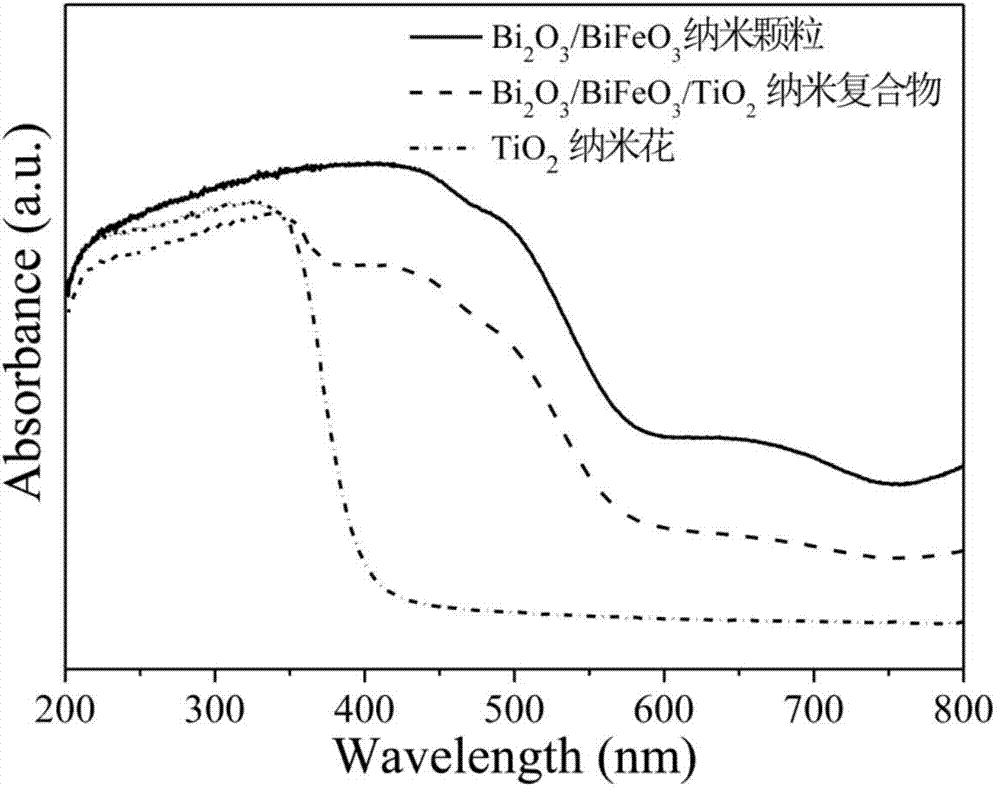

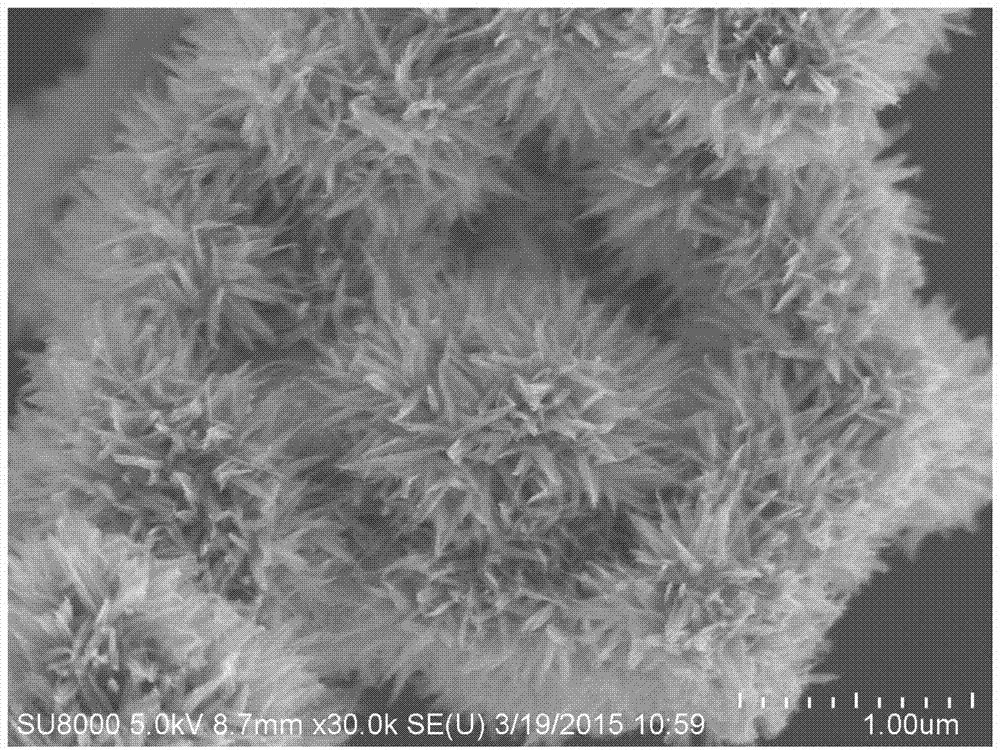

[0022] First prepare TiO 2 For nanoflowers, add 2ml of TBOT and 10ml of glycerol into 30ml of ethanol, stir magnetically for 5 minutes, mix the two solutions, continue stirring for 10 minutes, transfer the solution to a 100ml polytetrafluoroethylene reactor, and heat it at 180°C After reacting for 24 hours and cooling down to room temperature naturally, the collected products were washed with ethanol and centrifuged three times, dried at 80°C and then calcined in a muffle furnace at 450°C for 3h with a heating rate of 2°C / min. Second, the preparation of Bi 2 o 3 / BiFeO 3 Nanoparticles, weigh 0.9095g Bi(NO 3 ) 3 ·5H 2 O and 0.5050g Fe(NO 3 ) 3 9H 2 O was put into 20ml of ethylene glycol solution, stirred for 10min, put the sol in an oil bath at 80°C for 2h, then raised the temperature to 120°C and stirred until the solution was completely evaporated. The powder formed in the beaker was transferred to a 30ml crucible and calcined in a muffle furnace at 500°C for 2h at a...

Embodiment 2

[0024] According to the method of the present invention in embodiment 1, hydrothermal method prepares TiO 2 The amount of nanoflower TBOT was increased to 4ml, the amount of other raw materials and the experimental steps remained unchanged, and Bi 2 o 3 / BiFeO 3 / TiO 2 Nanoflower composites.

Embodiment 3

[0026] According to the method of the present invention in embodiment 1, hydrothermal method prepares TiO 2 The amount of nanoflower TBOT was increased to 6ml, the amount of other raw materials and the experimental steps remained unchanged, and Bi 2 o 3 / BiFeO 3 / TiO 2 Nanoflower composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com