Bismuth-based modified photocatalyst and preparation method and application thereof

A photocatalyst and modification technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of high Ag content and expensive catalyst cost, and achieve simple preparation methods and visible light utilization high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

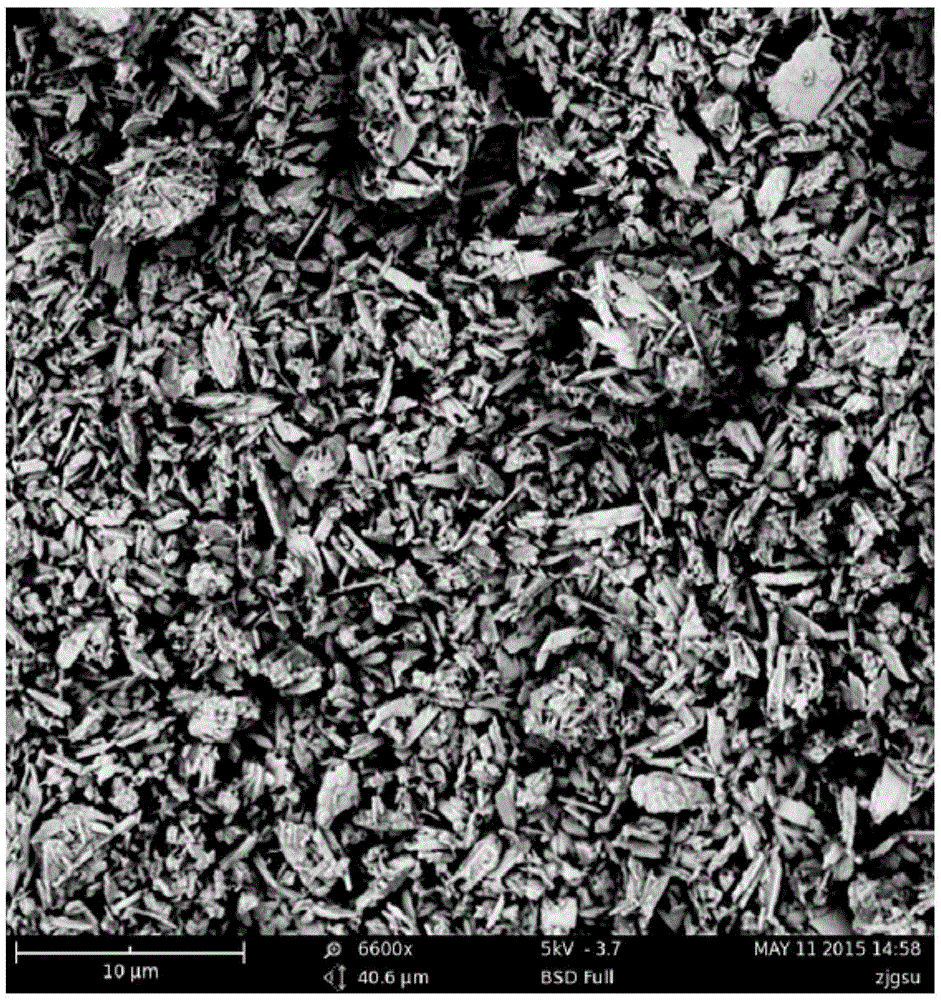

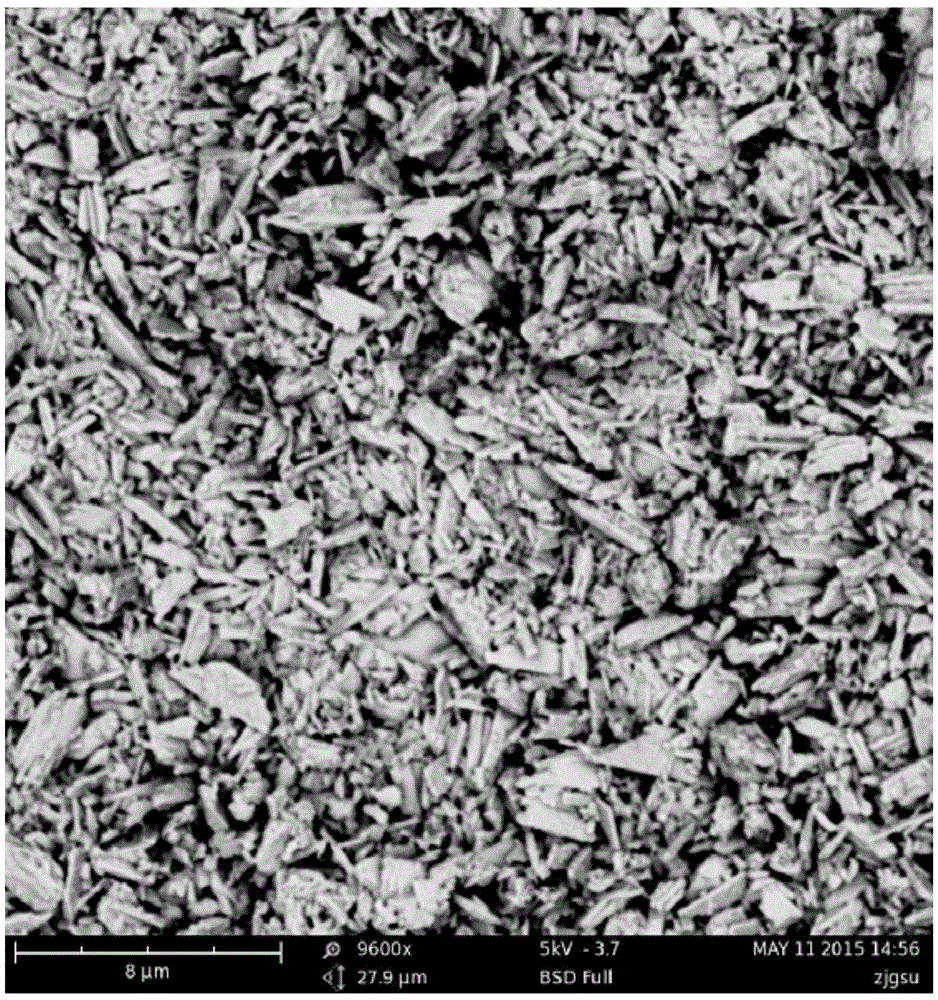

[0057] Photocatalyst AgI-RGO / α-Bi 2 o 3 -The preparation method of BiOI, the steps are as follows:

[0058] (1) Preparation of α-Bi 2 o 3 : Spread 3g of bismuth nitrate (pentahydrate) evenly on the bottom of the crucible to form a thin layer, heat up to 500°C at 5°C / min, and calcine at constant temperature for 3h.

[0059] (2) Take 1g of α-Bi 2 o 3 Dissolve in 50mL water, ultrasonically disperse for 60min to form a suspension, add 0.3562g KI solid to react, and stir for 60min;

[0060] (3) Add 0.0722 g of silver nitrate solid to the above solution, fully dissolve the reaction, stir for 60 min; then add 5 mg of graphene oxide (GO), ultrasonically disperse for 60 min, and stir for 60 min;

[0061] (4) Add 0.1mL of N 2 h 4 ·H 2 O, 80°C water bath for 10min, after the reaction, the suspension was washed 4 times with water, centrifuged, the supernatant was discarded, dried, and ground to obtain AgI-RGO / α-Bi 2 o 3 -BiOI.

[0062] Wherein, the preparation of graphene oxid...

Embodiment 2

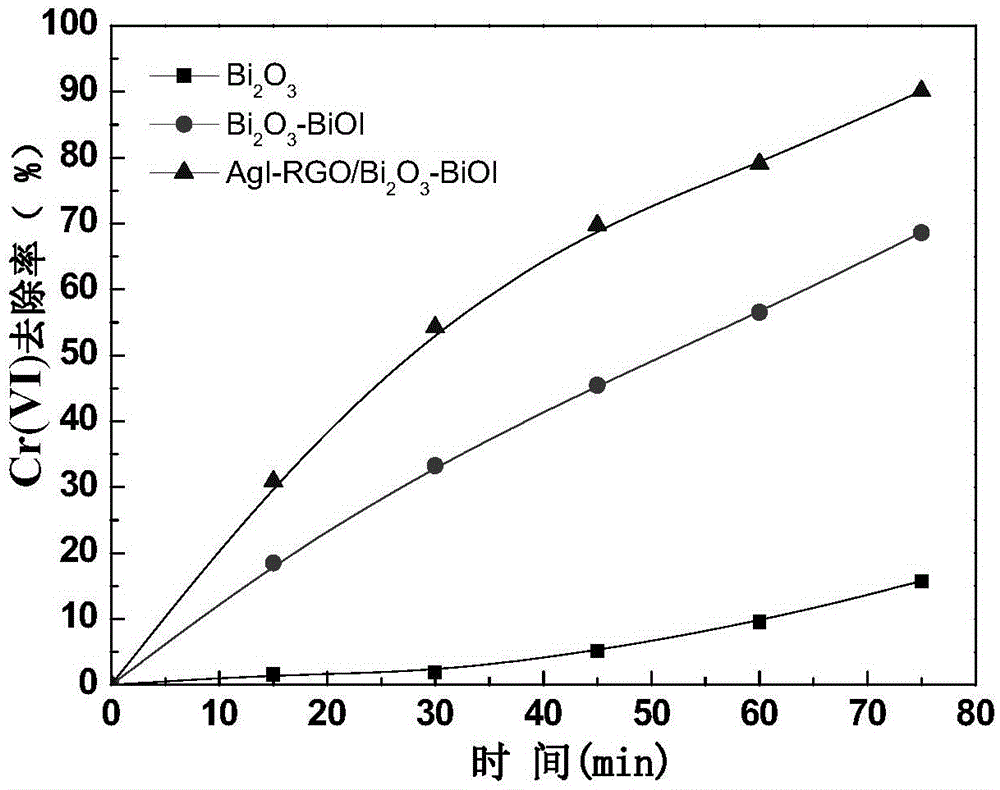

[0067] In 50mL of chromium-containing wastewater (Cr(VI) concentration 20.35mg / L), add 50mg of photocatalyst, do not adjust the pH, stir in the dark for 30min to adsorption equilibrium, fix the position of the light source, turn on the visible light source, and react for 75min. Photogenerated electrons reduce Cr(VI) to Cr(III), which is 100 times less toxic and prone to coordination precipitation.

[0068] Wherein the photocatalyst adopts the photocatalyst α-Bi prepared by embodiment 1 2 o 3 , α-Bi 2 o 3 -BiOI, AgI-RGO / α-Bi 2 o 3 -BiOI, to compare the effect of reducing Cr(VI), the results are as follows figure 2 .

[0069]Under the same conditions, the modified AgI-RGO / α-Bi 2 o 3 -BiOI vs α-Bi 2 o 3 , α-Bi 2 o 3 -The effect of reducing Cr(VI) by BiOI has been improved to varying degrees. Within 45min, AgI-RGO / α-Bi 2 o 3 -BiOI significantly accelerated the removal rate of Cr(VI). After 75min, AgI-RGO / α-Bi 2 o 3 -BiOI removal rate for Cr(VI), relative to α-Bi ...

Embodiment 3

[0071] Take 0.1g of prepared catalyst α-Bi 2 o 3 and AgI-RGO / α-Bi 2 o 3 -BiOI was dissolved in 0.5mL ethylene glycol, ultrasonically dispersed for 30min, drop-coated on conductive glass (FTO) (6cm*1cm), the size of drop-coating was 1cm*1cm, coated twice, 20μL each time, vacuum-dried at 80°C , to produce α-Bi 2 o 3 and AgI-RGO / α-Bi 2 o 3 -BiOI photocatalytic electrode.

[0072] Place the above electrodes in Na with a concentration of 0.5mol / L 2 SO 4 In the solution, under the 3-electrode system of the electrochemical workstation, the above electrode was used as the working electrode, the platinum sheet was used as the counter electrode, and the silver electrode was used as the reference electrode, and the flat band potential of the catalyst was measured in the dark. The parameters are: the amplitude is 5mV, and the frequency is 500, 1000, 3000Hz respectively.

[0073] Figure 3(a) and Figure 3(b) are α-Bi 2 o 3 and AgI-RGO / α-Bi 2 o 3 - Flat band potential map of Bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com