Complete equipment for pre-desliming floatation

A complete set of equipment and flotation technology, applied in flotation, solid separation, etc., can solve the problems of difficult dehydration of clean coal in flotation, fast flotation speed of high-ash fine mud, interference with stirring flow field, etc., to achieve improved separation Desliming effect, reducing the viscosity of flotation feed material, and shortening the effect of settling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

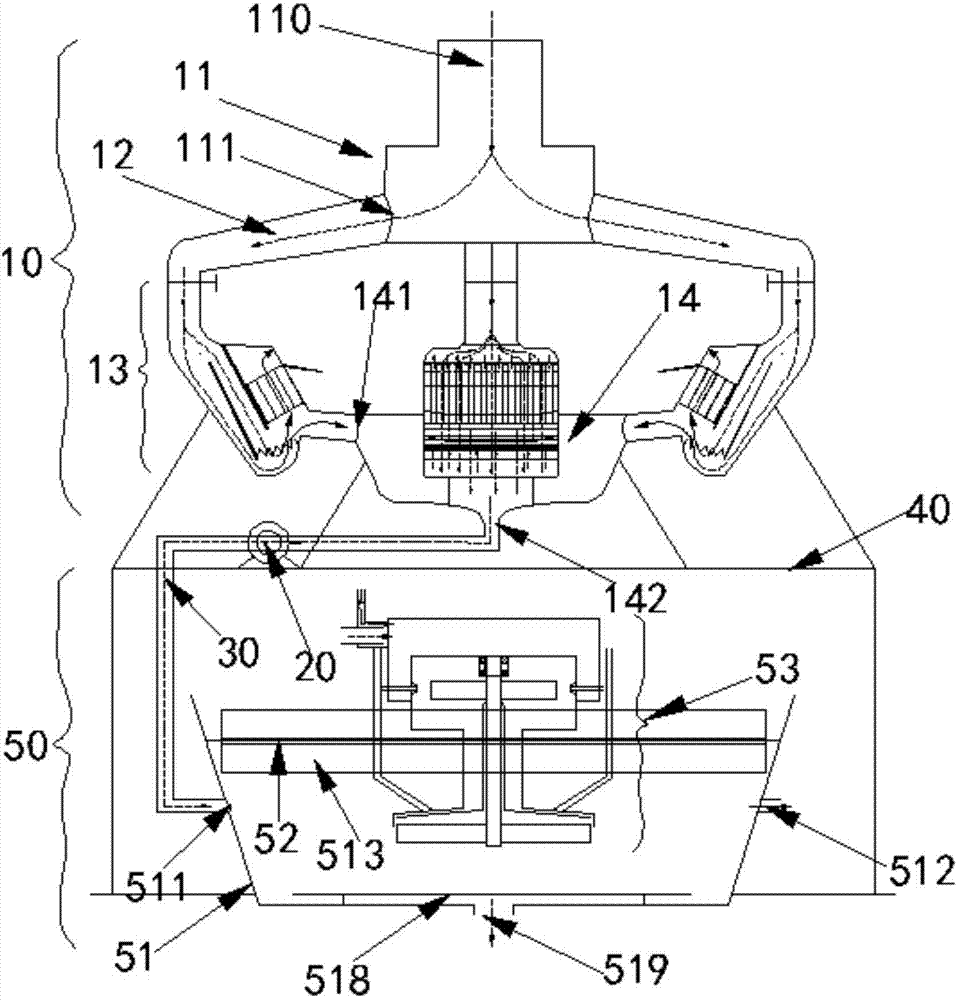

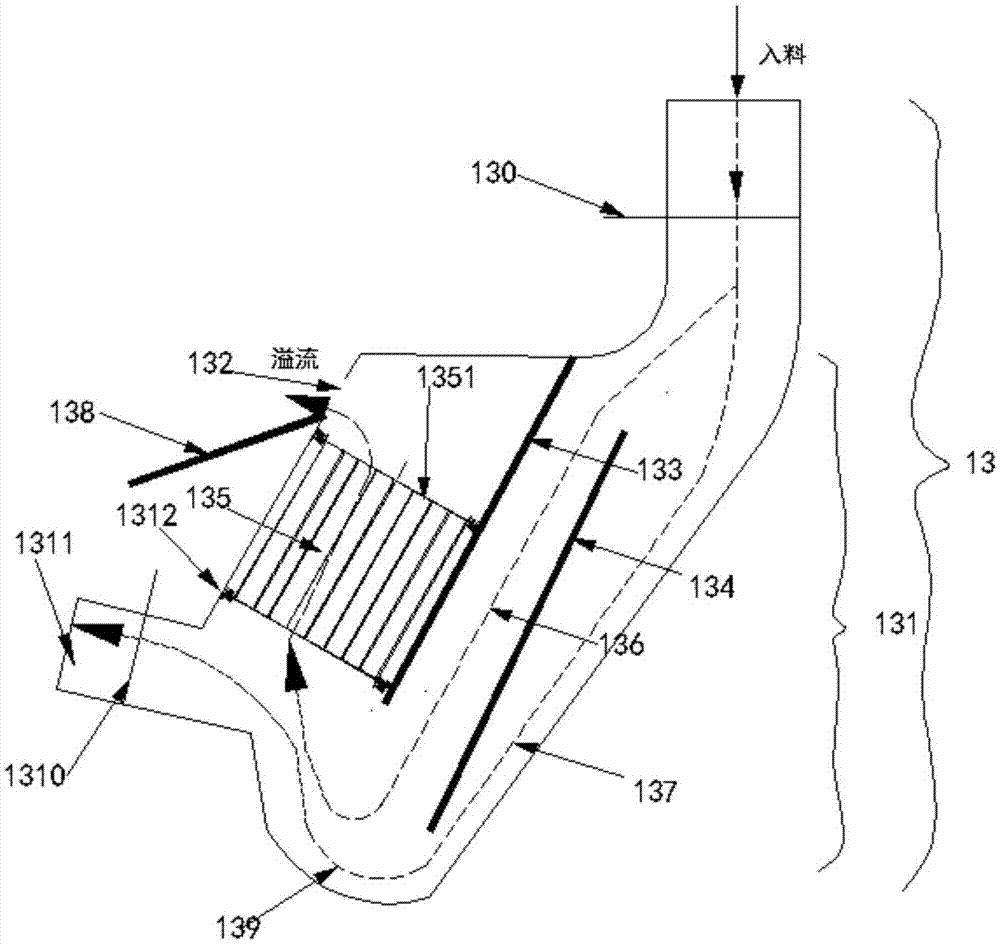

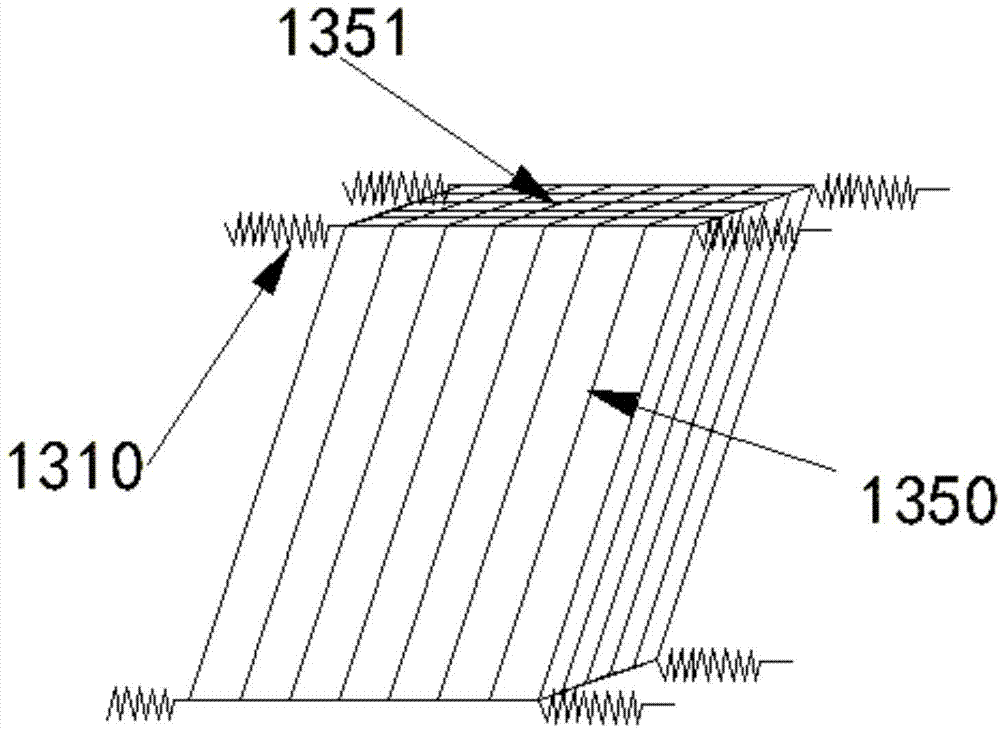

[0040] Such as Figure 1-7 As shown, in order to achieve the above object, the present invention adopts the following technical solutions:

[0041] A complete set of pre-desliming flotation equipment, including a self-interference elastic rectification desliming unit (10), a slurry delivery pump (20), a slurry delivery pipe (30), a support (40) and a connecting rod jet stirring suction flotation device (50).

[0042] The self-interference elastic rectification deslimer unit (10) includes a slurry feeding bin (11), a first feeding pipe (12), a self-interference elastic rectification deslimer (13), and an underflow collection bin (14).

[0043] The pulp feeding bin (11) is arranged above the self-interference elastic rectifying desilter (13), the upper end of the pulp feeding bin (11) is provided with a first feeding port (110), and the side walls are uniformly arranged There is an ore slurry distribution outlet (111) connected with the first feeding pipe (12).

[0044] The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com