Preparation method of ecological flocculant for removing phosphorus and algae from eutrophic water

A flocculant and eutrophication technology, which is applied in the field of preparation of ecologically safe flocculants, to achieve the effect of increasing the adsorption specific surface area, optimizing the lattice structure, and improving the phosphorus adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

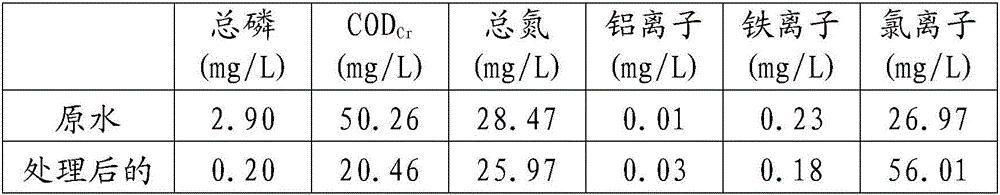

Embodiment 1

[0030] The flocculant preparation method of the present embodiment comprises the following steps:

[0031] The first step, material preparation: Weigh 30 g of commercially available polyaluminum chloride powder and 60 g of yellow clay.

[0032] The second step, clay pretreatment: after the yellow clay is pulverized and sieved (60 mesh), the particle size is less than 0.425mm. After mixing 60g of yellow clay with 180ml of water, add a concentration of 50mM diluted 182ml of hydrochloric acid was used to adjust the basicity to 70% to obtain a ready-to-use clay suspension.

[0033] The third step, preparation of polyaluminum chloride solution: after mixing 30g of polyaluminum chloride powder with 100ml of water evenly, add a dilute sodium hydroxide solution with a concentration of 50mM to the mixture while stirring to adjust the basicity to 70% , to obtain polyaluminum chloride solution.

[0034] The fourth step, composite reaction: slowly pour the polyaluminum chloride solution...

Embodiment 2

[0042] The flocculant preparation method of the present embodiment comprises the following steps:

[0043] The first step, material preparation: Weigh 60 g of commercially available polyaluminum chloride powder and 30 g of yellow clay.

[0044] The second step, clay pretreatment: after the yellow clay is pulverized and sieved (40 mesh), the particle size is less than 0.425mm. After mixing 30g of yellow clay with 90ml of water evenly, add a concentration of 30mM diluted Adjust the basicity to 70% with hydrochloric acid to obtain the ready-to-use clay suspension.

[0045] The 3rd step, preparation polyaluminum chloride solution: after 60g polyaluminum chloride powder is mixed with 200ml water evenly, to its mixed solution dropwise while stirring, concentration is 740.6ml dilute hydrochloric acid of 750mM to adjust the base degree to 70%, A polyaluminum chloride solution is obtained.

[0046] The fourth step, composite reaction: slowly pour the polyaluminum chloride solution ad...

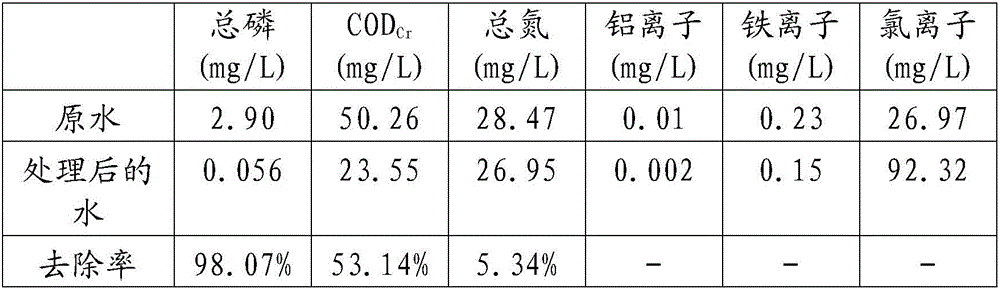

Embodiment 3

[0053] The flocculant preparation method of the present embodiment comprises the following steps:

[0054] The first step, material preparation: Weigh 45g of commercially available polyaluminum chloride powder and 45g of yellow clay.

[0055] The second step, clay pretreatment: after the yellow clay is pulverized and sieved (80 mesh), the particle size is less than 0.425mm. After mixing 45g of yellow clay with 130ml of water, add a concentration of 50mM diluted Adjust its basicity to 70% with 136.5 ml of hydrochloric acid to obtain the clay suspension for use.

[0056] The 3rd step, preparation polyaluminium chloride solution: after 45g polyaluminum chloride powder is mixed with 150ml water evenly, to its mixed solution dripping concentration is 834ml of dilute hydrochloric acid of 500mM while stirring to adjust its basicity to 70%, A polyaluminum chloride solution is obtained.

[0057] The fourth step, composite reaction: slowly pour the polyaluminum chloride solution adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com