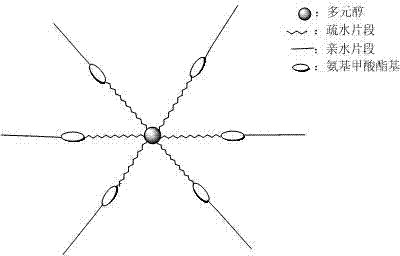

Star amphipathic polyurethane and preparation method thereof

An amphiphilic, polyurethane technology, applied in the field of polyurethane, can solve the problems of increasing toxicity, not involving star-shaped amphiphilic polyurethane, etc., and achieve the effects of reducing toxic side effects, excellent biodegradability, and improving drug loading rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A star amphiphilic polyurethane and a preparation method thereof. The preparation process of the preparation method is carried out under the conditions of 50-85°C, nitrogen protection and stirring, and the specific steps are:

[0027] Step 1: first mix polyester diol and diisocyanate, stir for 1-6 hours, then add polyethylene glycol monomethyl ether, and continue stirring for 1-7 hours to obtain a linear polyurethane prepolymer. in:

[0028] The mass ratio of polyethylene glycol monomethyl ether and polyester diol is 1: (1~5);

[0029] The mass ratio of polyethylene glycol monomethyl ether to diisocyanate is 1: (0.03-0.21).

[0030] Step 2: adding polyhydric alcohol into the linear polyurethane prepolymer, and continuing to stir for 1-5 hours to obtain star-shaped amphiphilic polyurethane. Wherein: the mass ratio of polyethylene glycol monomethyl ether to polyhydric alcohol is 1: (0.006~0.02).

[0031] In this embodiment: the polyester diol is polyca...

Embodiment 2

[0033] A star amphiphilic polyurethane and a preparation method thereof. The preparation process of the preparation method is carried out under the conditions of 50-85°C, nitrogen protection and stirring, and the specific steps are:

[0034] Step 1: firstly add polyester diol and diisocyanate into an aprotic solvent, stir for 1-6 hours, then add polyethylene glycol monomethyl ether, and continue stirring for 1-7 hours to obtain a linear polyurethane prepolymer. in:

[0035] The mass ratio of polyethylene glycol monomethyl ether and polyester diol is 1: (1~5);

[0036] The mass ratio of polyethylene glycol monomethyl ether to diisocyanate is 1: (0.03~0.21);

[0037] The mass ratio of polyethylene glycol monomethyl ether to the aprotic solvent is 1: (0.5-2).

[0038] Step 2: adding polyhydric alcohol into the linear polyurethane prepolymer, and continuing to stir for 1-5 hours to obtain star-shaped amphiphilic polyurethane. Wherein: the mass ratio of polyethylene...

Embodiment 3

[0041] A star amphiphilic polyurethane and a preparation method thereof. The preparation process of the preparation method is carried out under the conditions of 70-100°C, nitrogen protection and stirring, and the specific steps are:

[0042] Step 1: firstly add polyester diol and diisocyanate into an aprotic solvent, stir for 4-10 hours, then add polyethylene glycol monomethyl ether, and continue stirring for 5-10 hours to obtain a linear polyurethane prepolymer. in:

[0043] The mass ratio of polyethylene glycol monomethyl ether and polyester diol is 1: (5~10);

[0044] The mass ratio of polyethylene glycol monomethyl ether to diisocyanate is 1: (0.21~2.70);

[0045] The mass ratio of polyethylene glycol monomethyl ether to the aprotic solvent is 1: (2-5).

[0046] Step 2: adding polyhydric alcohol into the linear polyurethane prepolymer and continuing to stir for 3-7 hours to obtain star-shaped amphiphilic polyurethane. Wherein: the mass ratio of polyethylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com