Preparation methods for polyolefin alloy

A polyolefin and alloy technology, applied in the field of polyolefin alloys, can solve the problem of high content of random substances, and achieve the effects of improving productivity, good hydrogen sensitivity, and realizing rational utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

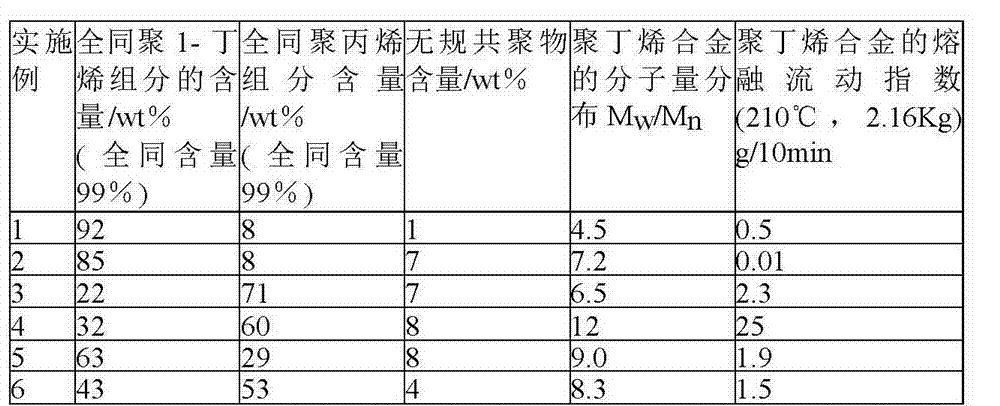

Examples

Embodiment 1

[0041] The reaction device for the preparation of polybutene alloy material by the continuous method process of the present invention is a pilot plant with a production capacity of 15kg / h, which is connected in series by three stainless steel pressure-resistant reactors with mechanical stirring devices and temperature control jackets. There is a separator between the first reactor and the third reactor, and the third reactor is followed by a flash tank. Cocatalyst triethylaluminum (5% by mass percent hexane solution), external electron donor diisopropyldimethoxysilane (3% by mass percent hexane solution), Ti-containing main catalyst (5% by mass percent % liquid paraffin mixed liquid), hexane, liquid butene-1, and hydrogen continuously enter the first reactor at a fixed rate to carry out butene-1 liquid phase polymerization. At the same time, the materials in the first reactor flow out into the second reactor at a certain rate to continue the homopolymerization of butene-1. Th...

Embodiment 2

[0046] Using the same continuous polymerization device and operating process as in Example 1, the cocatalyst is changed to triisobutylaluminum (5% hexane solution by mass percent), and the external electron donor is changed to methylcyclohexyldimethoxysilane (3% hexane solution by mass percent), the mol ratio of the Al element of triisobutylaluminum to the Ti element in the main catalyst is 80:1, the Al element of triethylaluminum and the external electron donor methylcyclohexyl di The molar ratio of methoxysilane is 8:1, and other conditions are the same as in Example 1.

[0047] The polymerization product is free-flowing granular or spherical fine powder particles, and the properties of the obtained polymer alloy are shown in Table 1.

Embodiment 3

[0049] Using the same continuous polymerization device as in Example 1, the molar ratio of Ti element to butene-1 in the main catalyst is 1 × 10 -6 : 1, the mol ratio of the Al element in the triethylaluminum and the Ti element in the main catalyst is 100:1, and the mol ratio of the Al element in the triethylaluminum and the external electron donor diisopropyldimethoxysilane is 10:1, control the flow rate of monomer propylene entering the third tank so that the flow rate ratio of butene-1 is 5:1. The temperatures of the three reactors are 30°C, 50°C, and 80°C, the pressures are controlled at 1.2MPa, 0.9MPa, and 2.0MPa, and the residence times are 0.5h, 6h, and 2h, respectively.

[0050] The polymerization product is free-flowing granular or spherical fine powder particles, and the properties of the obtained polymer alloy are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com