Sealant for large power LED, and large power LED

A sealant and high-power technology, which is applied in the field of high-power LED sealant, to achieve good working stability, improve heat dissipation effect, and ensure the effect of light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

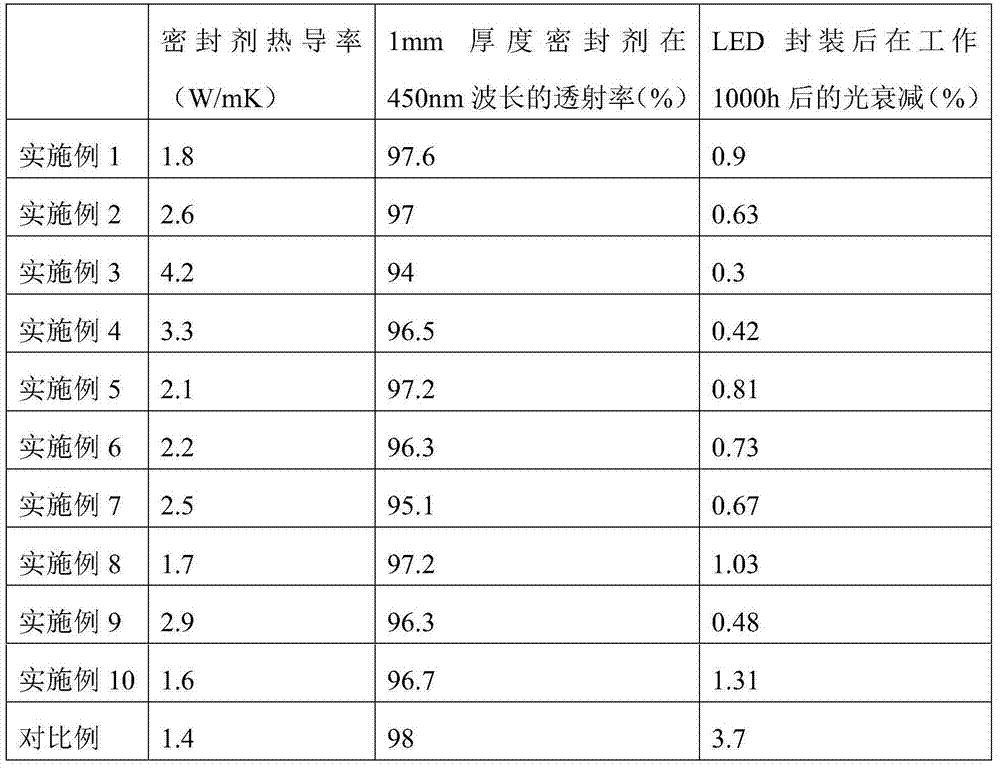

Embodiment 1

[0024] (1) Graphene is prepared by the technique of exfoliating graphite flakes with sodium cholate in liquid phase, or the graphene is first treated with strong acid, and then graphene is prepared by rapid thermal expansion above 2000°C per minute. Graphene preparation is a well-known technique , No longer go into details. The graphene was dispersed into the acetone solution by stirring first and then ultrasonic. The stirring time was 30 minutes, the ultrasonic time was 2 hours, and the power was 200W. The concentration of the obtained graphene solution is 1 mg / mL.

[0025] (2) Add silica gel to the graphene solution and stir for 30 minutes. The weight of graphene is 1% of silica gel.

[0026] (3) Put the mixed solution in a vacuum oven at 60°C for 1 hour to remove the acetone.

[0027] (4) Add the curing agent while stirring, the weight of the curing agent is 25% of the silica gel.

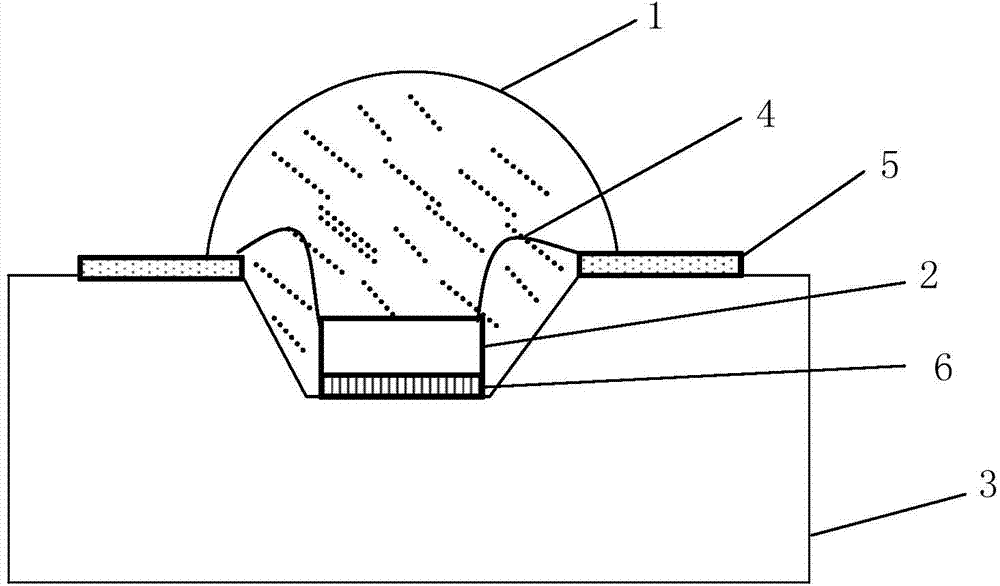

[0028] (5) Attachment figure 1 , Fill the graphene and silica gel composite material in the refl...

Embodiment 2

[0032] (1) Graphene is prepared by the technique of exfoliating graphite flakes with sodium cholate in liquid phase, or graphene is first treated with strong acid, and then graphene is prepared by rapid thermal expansion above 2000°C per minute. Graphene preparation is a well-known technique , No longer go into details. The graphene was dispersed into the acetone solution by stirring first and then ultrasonic. The stirring time was 30 minutes, the ultrasonic time was 2 hours, and the power was 200W. The concentration of the obtained graphene solution is 1 mg / mL.

[0033] (2) Add silica gel to the graphene solution and stir for 30 minutes. Graphene weight is 3% of silica gel.

[0034] (3) Put the mixed solution in a vacuum oven at 60°C for 1 hour to remove the acetone.

[0035] (4) Add the curing agent while stirring, the weight of the curing agent is 25% of the silica gel.

[0036] (5) Attachment figure 1 , Fill the graphene and silica gel composite material in the reflective cup ...

Embodiment 3

[0040] (1) Graphene is prepared by the technique of exfoliating graphite flakes with sodium cholate in liquid phase, or graphene is first treated with strong acid, and then graphene is prepared by rapid thermal expansion above 2000°C per minute. Graphene preparation is a well-known technique , No longer go into details. The graphene was dispersed into the acetone solution by stirring first and then ultrasonic. The stirring time was 30 minutes, the ultrasonic time was 2 hours, and the power was 200W. The concentration of the obtained graphene solution is 1 mg / mL.

[0041] (2) Add silica gel to the graphene solution and stir for 30 minutes. The weight of graphene is 10% of silica gel.

[0042] (3) Put the mixed solution in a vacuum oven at 60°C for 1 hour to remove the acetone.

[0043] (4) Add the curing agent while stirring, the weight of the curing agent is 25% of the silica gel.

[0044] (5) Attachment figure 1 , Fill the graphene and silica gel composite material in the reflect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com