Preparation method of red koji vinegar containing rich gamma-aminobutyric acid

A technology of aminobutyric acid and red yeast rice vinegar, applied in the direction of microorganism-based methods, vinegar preparation, biochemical equipment and methods, etc., can solve the problems that cannot be considered as natural food additives, GABA cannot be used in food, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

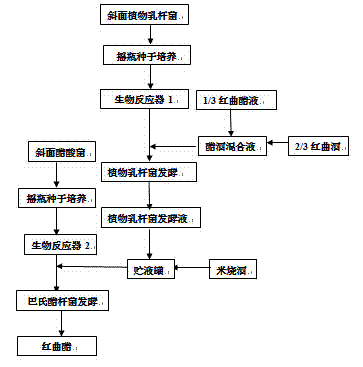

Image

Examples

Embodiment 1

[0034] 1. Carrier adsorption and proliferation of Lactobacillus plantarum

[0035] Scrape off the Lactobacillus plantarum cells cultured on the MRS solid slant medium, and use sterile water to make the number of bacterial cells 5×10 6 mL -1 plantarum suspension.

[0036] Take the suspension of Lactobacillus plantarum and inoculate it into a conical flask equipped with MRS liquid medium. The inoculum amount is 10% of the volume of MRS liquid medium. Lactobacillus plantarum seed solution.

[0037] Inject the Lactobacillus plantarum seed solution prepared in the previous step into tablet Membrane bioreactor 1, the injection volume is at the point where the liquid level exceeds the height of the carrier by 4cm. Open 1 / 4 of the intake valve, let in sterile air, and the air bubbles drive the Lactobacillus plantarum seed liquid backflow cycle, the bacterial cells of Lactobacillus plantarum are absorbed by the polypropylene hollow fiber carrier, and the remaining liquid enters th...

Embodiment 2

[0052] 1. Carrier adsorption and proliferation of Lactobacillus plantarum

[0053] Scrape off the Lactobacillus plantarum cells cultured on the MRS solid slant medium, and use sterile water to make the number of bacterial cells 2×10 6 mL -1 plantarum suspension.

[0054] Take the suspension of Lactobacillus plantarum and inoculate it into a conical flask equipped with MRS liquid medium. The inoculum amount is 10% of the volume of MRS liquid medium. Lactobacillus plantarum seed solution.

[0055] Inject the Lactobacillus plantarum seed solution prepared in the previous step into tablet Membrane bioreactor 1, the injection volume is at the point where the liquid level exceeds the height of the carrier by 4cm. Open 1 / 4 of the intake valve, let in sterile air, and the air bubbles drive the Lactobacillus plantarum seed liquid backflow cycle, the bacterial cells of Lactobacillus plantarum are absorbed by the polypropylene hollow fiber carrier, and the remaining liquid enters th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com