Novel copper finery oxy-fuel combustion system

An all-oxygen combustion and copper refining technology, applied in the field of new-type copper refining furnace all-oxygen combustion system, can solve the problems of increased operating costs, low oxygen content, increased operating costs, etc., and achieves simple and easy operation methods and reduced NOX emissions. , the effect of reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

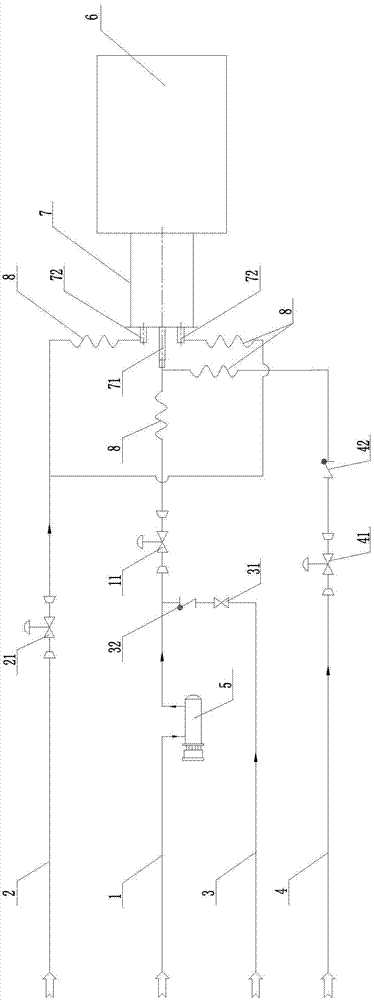

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0018] see figure 1 As shown, a new copper refining furnace oxy-fuel combustion system includes a fuel pipeline system, a gas-supporting pipeline system, a refining furnace 6 and a control system. In this embodiment, the reverberatory furnace 6 is used as the refining furnace 6 . The fuel pipeline system includes a fuel pipeline 1 for supplying fuel, a heating device 5 arranged on the fuel pipeline 1 for heating the fuel, a fuel regulating device arranged on the fuel pipeline 1 and behind the heating device 5 Valve 11. In this embodiment, the fuel is heavy oil, and the heating device 5 is a heavy oil electric heater 5. The temperature of the fuel after heating should exceed 100°C. Of course, natural gas can also be used as fuel. For example, when natural gas is used as fuel, Then there is no need to use a heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com